OTZ 70x150x0.5 TinplateSPEC

OTZ 70x150x0.5 TinplateDetails

OTZ 70x150x0.5 TinplatePacking list

- SKU

- NB001044

- Model

- 70 * 150 * 0.5 (without punching)

- Thickness (mm)

- 0.5

- Product size

- 70*150mm

- Encasement

- 500 pieces/bag

- Tin plating amount

- E4

- Whether to punch holes

- No

- corner shape

- Rounded corners, no punching

Introduction

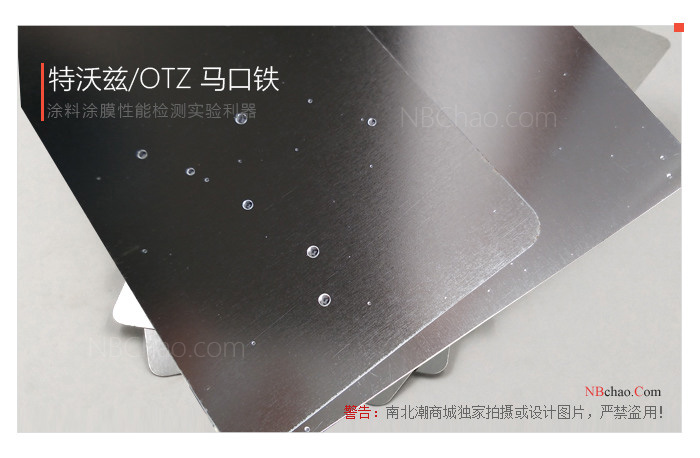

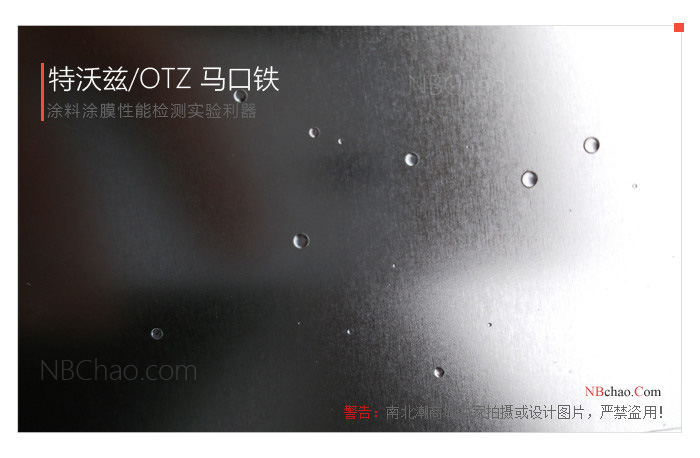

Twoz/OTZ 70x150x0.5mm tinned iron plate is a customized type, tinplate thickness 0.5mm. Tinplate iron plate is a thin iron plate with tinned surface and rectangular rounded corners, which is made of plate plate after heating, hot rolling, pickling, cold rolling, heat treatment, leveling, electro-tin plating and then shearing according to user needs, and finally formed a tinplate plate. Tinplate is often used for proofing in the paint and ink industry and is a consumable product.

Parameters

| Model | Thickness (mm) | Dimensions (mm) | wrap | Amount of tinning | remark |

| 70x150x0.5 (without punching) | 0.5 | 70x150 | Each package is 500 tablets | E4 | Rounded corners, no perforations |

Note: The tinned iron plates sold in the North and South Tide Mall are sold in whole packages, with 500 pieces per package (free shipping including tax).

Actual picture of the product

- 1Discussion and analysis of tinplate mass and standard

- 2How to control Coating Viscosity when Tinplate painting?

许腾辉 - 《马口铁涂装时涂料粘度的控制》

- 3Reasons and Solutions of Strip Defects on the Surface of Cold Rolled Tinplate

周景龙 - 《马口铁冷轧板表面缺陷研究》

- 4Analysis of Thickness Determination Method of Tinplate and Chromium-plated Iron Coating

刘九强 - 《马口铁、镀铬铁涂油量的测定方法》

- 5Analysis of Tinplate Surface Spreader Process

成文 - 《马口铁表面涂布工艺》

- 6Tinplate Spreader printing process "flower stand injury" problems and measures

徐灏 - 《马口铁“花架伤”弊病的影响因素及解决对策》

- 7Tinplate Spreader FAQ Analysis Solutions

曾建辉 - 《马口铁涂布常见问题的处理》

- 8What factors affect the inks hue in tinplate printing?

崔建荣 - 《马口铁印刷中影响油墨色相的因素分析》

- 9Discuss and analyze the surface coating treatment scheme of tinplate

孙秋菊; 赵桂贞; 郑弘; 盛金满 - 《马口铁表面涂层处理的研究》

- 10Causes and measures of defects of "white spots" on tinplate surface

王健; 杜明山; 王锋; 房锦超 - 《马口铁表面“白斑”缺陷成因分析》

- 1WJ 2669-2005《Specification for cathode electrophoresis paint for shell》

- 2 901-2021《Technical specification for the application of fireproof coatings for tunnels》

- 3 10254-2022《Green building materials evaluation fire retardant coating》

- 4GB 15442.1-1995《Classification and test methods for fire retardancy of finishing fire retardant paints--Classification for fire retardancy》

- 5GB 28375-2012《Fireproof coatings for concrete structure》

- 6GB 12441-2018《Finishing fire resistant coating》

- 7GB 14907-2018《Fire resistive coating for steel structure》

- 8HG/T 5187-2017《Automobile axle spring anticorrosive primer》

- 9GB/T 14907-2018《Fire resistive coating for steel structure》

- 10GB/T 9779-2015《Multi-layer coatings for architecture》

70x150x0.5

70x150x0.5