Defelsko Positector 200 Series Ultrasonic Thickness Gauge nondestructive Coating thickness

Defelsko SPEC

Defelsko Details

Defelsko Packing list

- SKU

- NB001097

- Probe style

- Split probe

Positector 200 Series Ultrasonic Thickness GaugesIntroduction

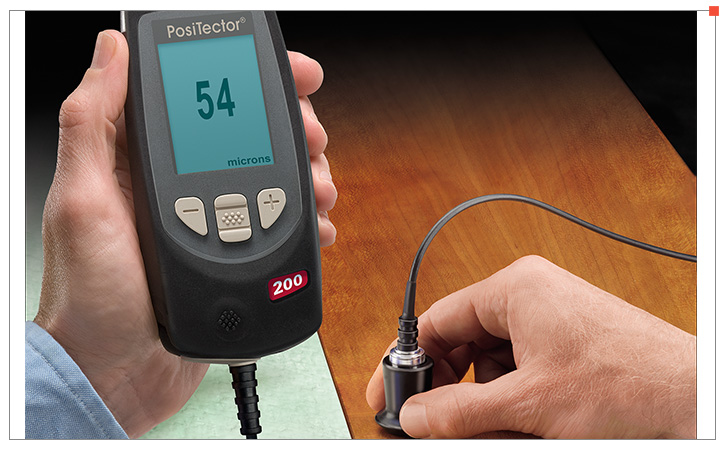

The Defelsko Positector 200 series ultrasonic Thickness Gauge is a handheld non-destructive Tester imported from Defelsko in the United States, which uses the principle of ultrasonic Thickness Gauge and can be used in a wide range of coating thickness measurement of polymers such as wood, concrete, plastics, composite materials, and metals. The Positector 200 Ultrasonic Thickness Gauge is available in Advanced and Standard versions for different applications, with the Advanced Thickness Gauge measuring up to 3 layers of coating thickness.The Positector 200 ultrasonic Thickness Gauge is available in B, C, and D probes for different applications.

The Defelsko Positector 200 Ultrasonic Thickness Gauge is the same as the Positector 6000 in terms of simplicity, durability, accuracy, and versatility.

Positector 200 Series Ultrasonic Thickness Gaugesstructure

The basic structure of the Defelsko Positector 200 gauge is as follows: IR and USB interfaces, a rubber case, a large LCD display with backlit display, a reading indicator, a - and + button, a confirmation button, a probe with abrasion resistance, and a breakage resistant wire.

Comparison of standard and advanced type

1. The standard Positector 200 ultrasonic Thickness Gauge is used to measure the total thickness of the coating

2. The advanced Positector 200 ultrasonic Thickness Gauge can measure the total thickness of the coating or the independent thickness of up to 3 layers, and can output a diagram, which can help to analyze the coating in detail.

In addition, advanced ultrasonic Thickness Gauges can display graphic data on a variety of systems including Android, IOS, tablets, computers, and more.

Positector 200 Series Ultrasonic Thickness GaugesLive shot

Power on/off method

1. Boot method: Defelsko Positector 200 ultrasonic Thickness Gauge can be turned on by pressing any button.

2. Shutdown method: The Thickness Gauge will automatically shut down after 3 minutes without any operation, and the - button and + button can also be shut down for at least 5s.

Operating Principle:

Power on – probe zeroing – known thickness calibration – measurement

1. Apply the couplant to the surface of the object

2. The Defelsko Positector 200 ultrasonic Thickness Gauge is turned on and the probe is placed flat on the surface of the object to be measured

3. When you hear two "beeps" or the indicator light of the ultrasonic Thickness Gauge is on, the LCD screen will display the measurement results after lifting the Positector 200 probe. If you want to measure a second measurement, press the probe at the same point or away from the probe in another position.

4. After the Positector 200 ultrasonic Thickness Gauge is measured, wipe off the couplant, put the Thickness Gauge back into the instrument, and the main unit and probe do not need to be disassembled.