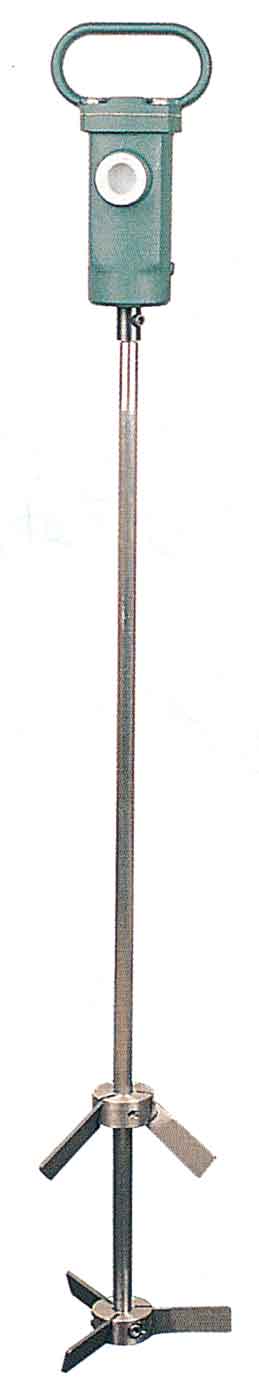

MODERNER QSJ-0.5 Pneumatic Handheld Stirrer

Moderner QSJ-0.5 Pneumatic Handheld StirrerSPEC

Moderner QSJ-0.5 Pneumatic Handheld StirrerDetails

Moderner QSJ-0.5 Pneumatic Handheld StirrerPacking list

- SKU

- NB011222

- Input Power

- ≥0.5kw

- Impeller configuration

- Φ150mm

- Machine Weight

- 4kg

- Speed range

- ≤1800r/min

- air consumption

- ≤22L/s

- Use air pressure

- 0.63MPa

- inner diameter of trachea

- 13mm

product description

This machine is suitable for blending and stirring various paints, pulps, dyes, coatings and emulsions. It can improve labor efficiency, reduce labor intensity and improve Operating Conditions. Since this machine uses compressed air as the power source, it is suitable for mixing volatile and flammable paints or coatings, and is also suitable for use in explosion-proof workshops.

use

Insert the air tube into the connecting tube of the machine, connect the air source and you can use it.

Precautions

1. The compressed air used is kept at 0.63MPa and purified. If the air pressure is too high, wear will increase and life will be affected; if the air pressure is too low, efficiency will decrease.

2. Three major components, filter, pressure regulating valve and lubricator, must be placed in the gas line. In the absence of these three major components, lubricating oil must be injected from the air inlet every 2 to 3 hours. Use No. 20 engine oil in summer and No. 10 engine oil in winter.

3. Before connecting the machine to the air line, the air line should be opened first to discharge the dirt in the air line.

4. Pay attention to taking good care of the equipment during work, and do not throw it away randomly to avoid damaging the parts.

QSJ-0.5

QSJ-0.5