YUSHINDT CM10FN platings Thickness Gauge

yushindt CM10FN Coated platings Thickness GaugeSPEC

yushindt CM10FN Coated platings Thickness GaugeDetails

yushindt CM10FN Coated platings Thickness GaugePacking list

- SKU

- NB011748

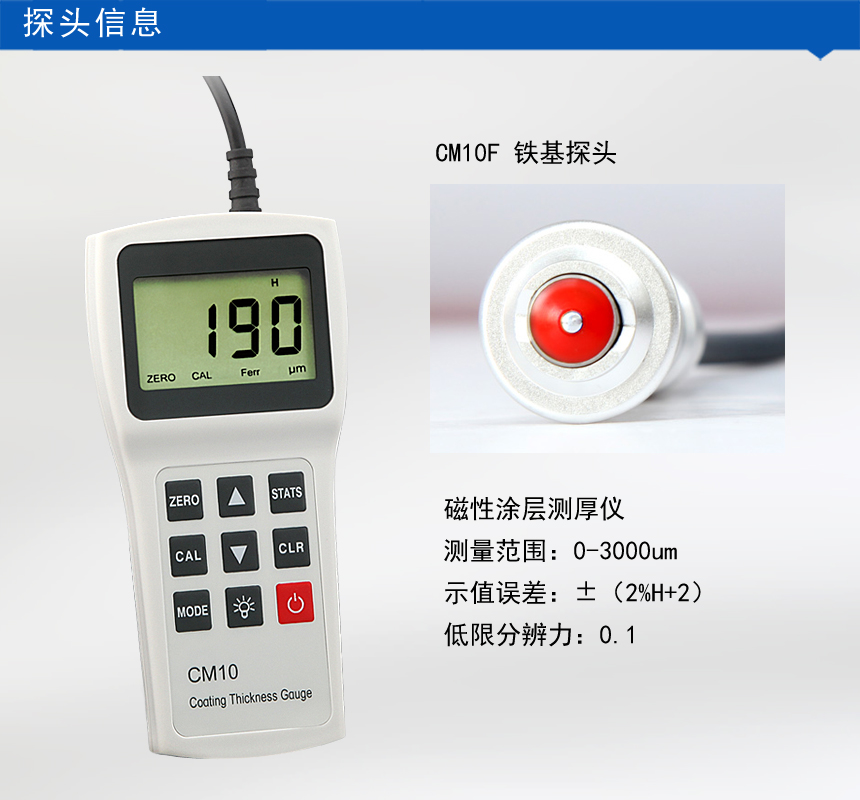

- Measurement principle

- Magnetic Induction + eddy Current

- Measurement range

- 0~1500μm

- margin of error

- ±2%

- resolution

- 0.1μm

- Minimum measurement surface

- Φ20mm

- Minimum radius of curvature

- Convex 5mm

- thinnest substrate

- 0.5mm

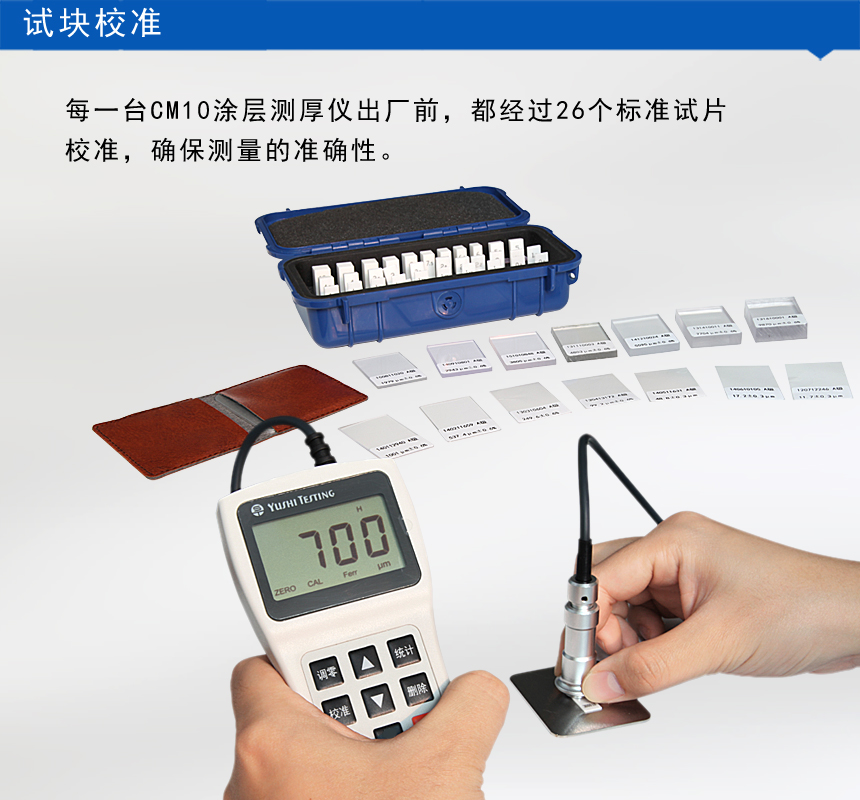

- Calibrated mode

- One point calibrated, two point calibrated

- statistical function

- Measurement times, MAX Maximum, MIN Minimum, Average, Standard deviation

- Power Supply

- Two 1.5V AA batteries, when the battery is low, there is a low Voltage prompt

- Display screen

- High contrast ratio LCD screen (LED backlight)

- Operating temperature

- -10~50℃

- Voltage prompt

- Yes.

- Battery life

- Use time is greater than 35h

- Weight

- 200G (including battery)

- Dimension

- 149*73*32mm

Applications: Widely used in electronics, power plants, petrochemical, aviation, construction and other fields. For example, it is suitable for magnetic metal surface painting, automobile surface painting, magnetic metal surface plating (door handle), etc.

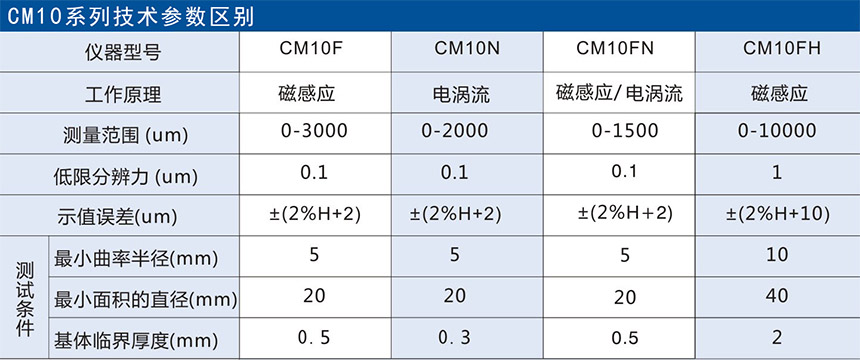

Brief description: Dual-purpose version with a range of measurement applications for CM10F and CM10N

Principle:

Magnetic induction principle (Fe): Measure the thickness of non-magnetic coating layers on ferromagnetic metal substrates such as steel and iron, such as paint layers, various anti-corrosion coatings, coatings, powder coatings, plastics, rubber, synthetic materials, phosphate layers, chromium, zinc, lead, aluminum, tin, cadmium, etc.

Eddy current principle (NFe): Measure the thickness of all non-conductive layers on non-ferromagnetic substrates such as copper, aluminum, stainless steel, etc., such as paint layers, various anti-corrosion coatings, coatings, powder coatings, plastics, rubber, synthetic materials, oxide films, phosphate films, etc.

CM10FN

CM10FN