Defelsko PosiTest AT-A 20mm Pull-off adhesion Tester 20mm kit size

SE-

TIANDIXINGHUO TC-A20 Automatic Adhesion Tester with 20mm kit$ 1902.00SE

TIANDIXINGHUO TC-A20 Automatic Adhesion Tester with 20mm kit$ 1902.00SE -

TIANDIXINGHUO XH-M Adhesion Tester Pull-off adhesion Detector 20mm$ 1424.00SE

TIANDIXINGHUO XH-M Adhesion Tester Pull-off adhesion Detector 20mm$ 1424.00SE -

KOSON KS-M coating adhesion Detector 20mm$ 917.00SE

KOSON KS-M coating adhesion Detector 20mm$ 917.00SE -

Defelsko PosiTest AT-M 50mm Pull adhesion instrument kit size 50mm Manual$ 3086.00SE

Defelsko PosiTest AT-M 50mm Pull adhesion instrument kit size 50mm Manual$ 3086.00SE -

Defelsko PosiTest AT-A 50mm Adhesion Tester kit Size 50mm Fully automatic$ 4089.00SE

Defelsko PosiTest AT-A 50mm Adhesion Tester kit Size 50mm Fully automatic$ 4089.00SE

Defelsko ATA20A Adhesion Tester (Pull Type)SPEC

Defelsko ATA20A Adhesion Tester (Pull Type)Details

Defelsko ATA20A Adhesion Tester (Pull Type)Packing list

- SKU

- NB001181

- Measurement mode

- fully automatic

- Kit diameter

- 20mm

- Range

- 0.7~24MPa/100~3500psi

- Resolution

- 0.01MPa(1psi)

- Accuracy

- ±1%

- typical application

- Metal coatings

- Data storage

- 100,000 readings, 1000 batches

- Display

- Color touch LCD screen

- Force unit

- MPa、psi

- Power Supply

- Rechargeable NiMH battery

- meet the standard

- ASTM D4541、ASTM D7234、ISO 4624、ISO 16276-1、AS/NZS 1580.408.5等

- software

- PosiTector APP (iOS and Android)

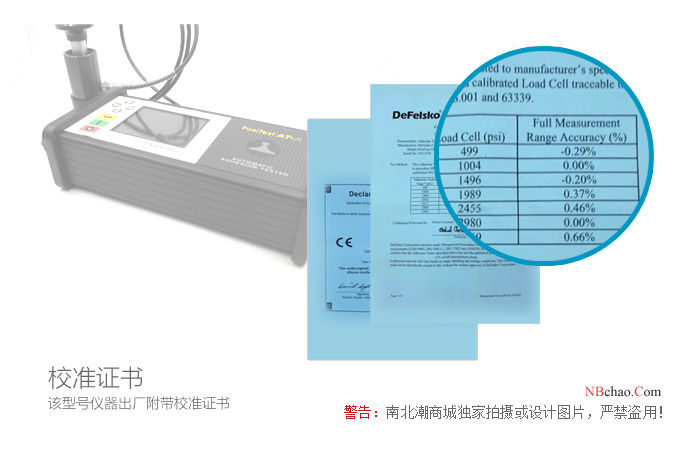

- Calibrated Certificate

- Yes.

- Accessories

- ATA20:20 mm kit (20), 20 mm trimmer, and 20 mm kit transparent sleeve

Introduction

The Defelsko Pull-Off Adhesion Tester PosiTest AT-A 20mm uses a 20mm jack and is suitable for a maximum adhesion of 350psi, unlike the manual typePosiTest AT-M 20mm,PosiTest AT-A 20mmThe pull-off adhesion Tester is fully automatic, and the electronically controlled hydraulic pump automatically generates a smooth and continuous pull-out force, which greatly reduces the impact of the manual pull-out process on the measurement results due to uneven force on the operator. The pull-off adhesion Tester is operated and controlled by a touch keyboard, and the shell has the advantages of waterproof and dustproof.

Features

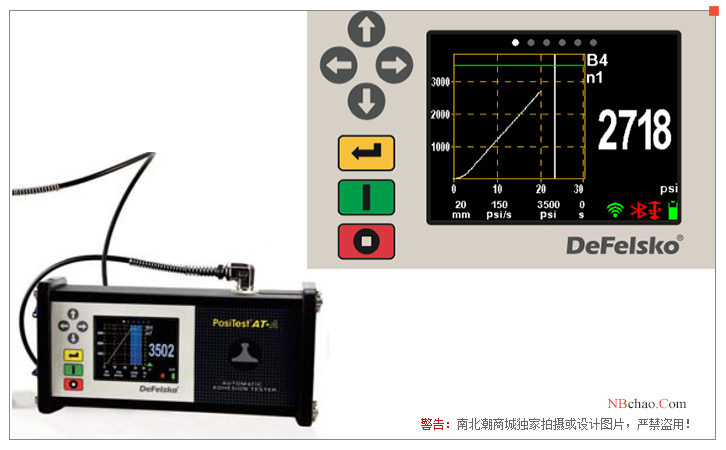

1. Color LCD screen, touch button operation, no need to wear gloves.

2. The electronically controlled hydraulic pump automatically produces a smooth and continuous pulling force. Reduce the influence of uneven force on the measurement results caused by manual operation of the staff.

3. Built-in rechargeable battery, each charge can be continuously tested 200 times. While the battery is charging, AC power can also be used for testing.

4. It adopts environmentally friendly sealed shell, which fully conforms to and exceeds IP65 level, and has strong waterproof, dustproof and shockproof characteristics.

5. Rubber grip with adsorption, the base is stable and non-slip.

6. Automatically align and position the top sub, so that it can be accurately measured on smooth or rough surfaces.

7. There are 10, 14, 20 and 50mm jacks to choose from to meet the test needs of different adhesion ranges.

10mm: 1400psi (96MPa); 14mm:7000psi(50MPa);20mm:3500psi(24MPa);50mm:560psi(3.8MPa)

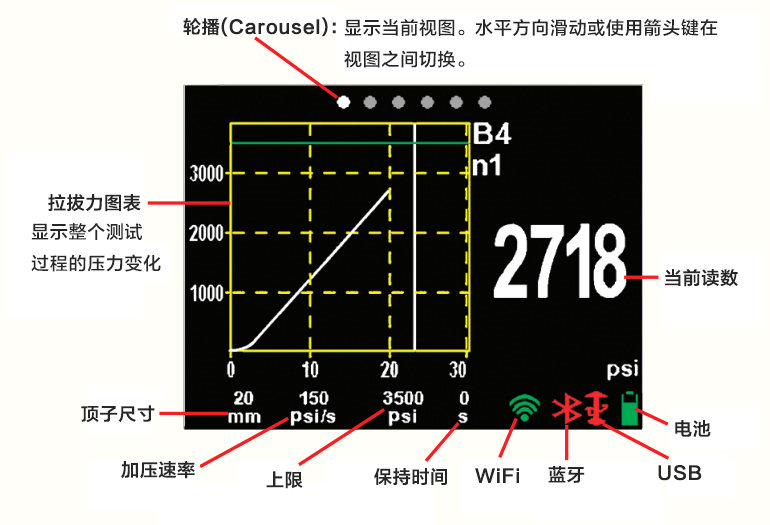

8. The user can adjust the tensile rate, the limit of the tensile force and the holding time.

9、PosiTest AT-A 20mmPull-off adhesIon MeterIt can be tested horizontally or vertically, and the LCD display can be rotated.

10. The pressure system is calibrated by traceable NIST load cell, and the accuracy reaches ±1% (full scale)

Product structure diagram

Product interface diagram

Positector APP features

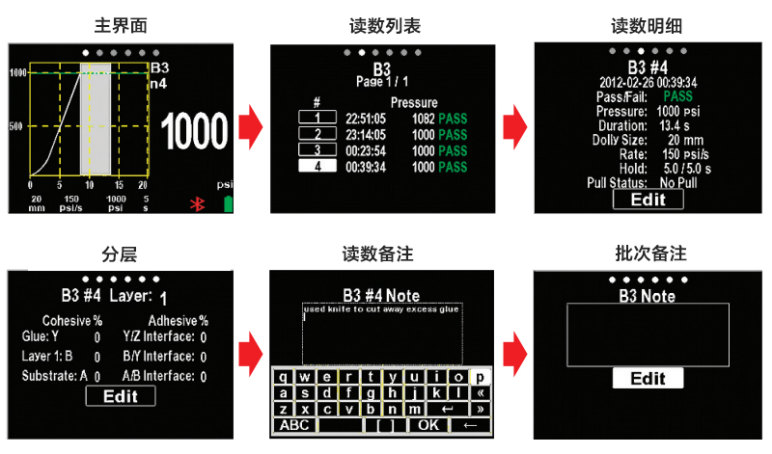

1. Add pictures or text through the camera or keyboard.

2. Create customized, professional PDF reports.

3. Measurement data can be shared, backed up, synchronized and recorded.

4. Automatic pairing Bluetooth (BLE) connection.

5. Check the help manual to learn how to use it.

Meets standards

The Defelsko Pull-Off Adhesion Tester PosiTest AT-A complies with a variety of international standards, including ASTM D4541,ASTM D7234、ISO 4624、ISO 16276-1, AS/NZS 1580.408.5 and others.

Storage and recording features

1、The built-in memory of the adhesIon Meter can store up to 100,000 pieces of data(including tensile force value, pressurization rate, test time, and top size), which can be divided into 1000 groups.

2. Record the adhesion test results (pass/fail) and the firmness of adhesion (good, fair, poor).

3. You can install the free Positector APP on your mobile device and connect wirelessly. (Available for IOS and Android)

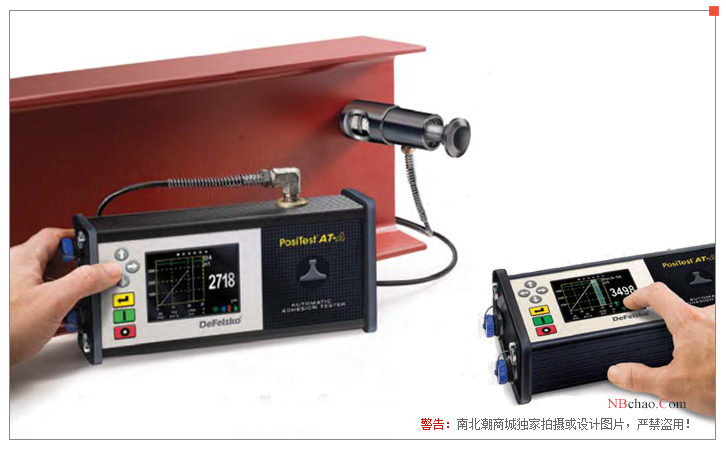

Actual picture of the product

PosiTest AT-A 50mm and 20mm comparison

| Model | PosiTest AT-A 20mm | PosiTest AT-A 50mm |

| Top sub specifications | 20mm | 50mm |

| Typical Applications | coating on metal | Coatings on concrete, wood, plastic |

| range | 0.7 – 24 MPa 100 – 3500 psi 100 – 7550 N | 0.4 – 3.8 MPa 50 – 560 psi 100 – 7550 N |

| resolution | 0.01 MPa (1 psi) | |

| precision | ±1% full scale | |

| fittings | ATA20: 20 mm top (20), 20 mm edge cutter and 20 mm top clear sleeve ATA50: 50 mm jack (8), 50 mm Edge cutter and 50 mm Top transparent sleeve | |

- 1HG/T 2406-2014《Pressure sensitive adhesives label for general purpose》

- 2SH/T 3022-2019《Design standard for anticorrosion coating of equipment and piping in petrochemical industry》

- 3ISO 2819-2017《Metallic coatings on metallic substrates - Electrodeposited and chemically deposited coatings - Review of methods available for testing adhesion (Third Edition)》

- 4ASTM D7234-2012《Standard Test Method for Pull-Off Adhesion Strength of Coatings on Concrete Using Portable Pull-Off Adhesion Testers》

- 5GB/T 39289-2020《Determination of the adhesion strength—Plastic and metal》

- 6ISO 12944.6-2018《Paints And Varnishes - Corrosion Protection Of Steel Structures By Protective Paint Systems - Part 6: Laboratory Performance Test Methods》

- 7GMW 4205《Eletroplating standards for zinc-nickel alloys》

- 8HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 9HG/T 2454-2014《Solvent-thinned polyurethane coatings (two-component)》

- 10TB/T 2965-2011《Technical specification for waterproof layer of railway concrete bridge》

ATA20A

ATA20A