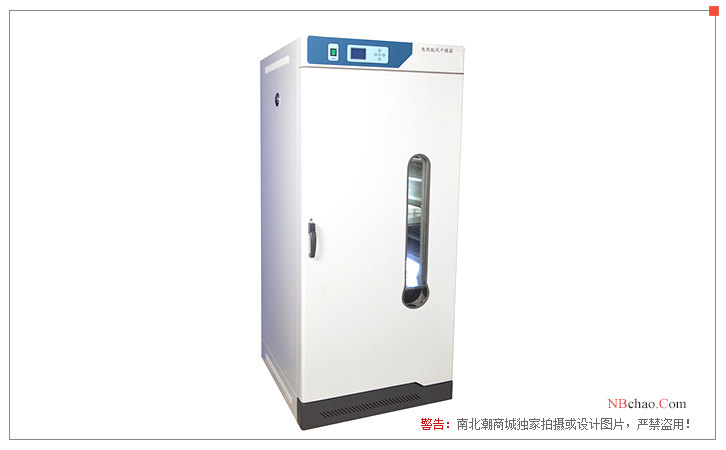

Shanghai JIECHENG DHG-9625AE Electric Forced Air Drying Oven

-

BENTING CBGLL-625BE vertical intelligent Forced Air Drying Oven 300 ℃/625L

BENTING CBGLL-625BE vertical intelligent Forced Air Drying Oven 300 ℃/625L -

YIHENG DHG-9625A Drying Oven volume 620L temperature control: 10~300 ℃$ 2287.00SE

YIHENG DHG-9625A Drying Oven volume 620L temperature control: 10~300 ℃$ 2287.00SE -

HUITAI BPG-9620A precision blast drying oven volume 620L microcomputer temperature control$ 1835.00SE

HUITAI BPG-9620A precision blast drying oven volume 620L microcomputer temperature control$ 1835.00SE -

Kenton 101-4S pointer electric Forced Air Drying Oven, stainless steel inner tank 300 ℃/640L$ 1011.00SE

Kenton 101-4S pointer electric Forced Air Drying Oven, stainless steel inner tank 300 ℃/640L$ 1011.00SE -

BOZHEN DHG-9625A vertical Forced Air Drying Oven$ 1785.00SE

BOZHEN DHG-9625A vertical Forced Air Drying Oven$ 1785.00SE

JieCheng DHG-9625AE Type II vertical Forced Air Drying OvenSPEC

JieCheng DHG-9625AE Type II vertical Forced Air Drying OvenDetails

JieCheng DHG-9625AE Type II vertical Forced Air Drying OvenPacking list

- SKU

- NB011848

- Temperature range

- RT+10~300℃

- Temperature Fluctuation

- ±0.1℃

- Temperature Resolution

- 0.1℃

- Volume

- 600L

- Interior size

- 650*700*1300mm

- Chamber material

- 304 stainless steel

- Shelf (std.)

- 2pcs

- Timer

- 1~9999min

- Power supply Voltage

- AC 220V 50Hz

- Input Power

- 800W

- Environmental temperature

- RT+5~40℃

- Dimensions

- 820*800*1600mm

- Display mode

- LCD digital display

- Door opening method

- Open the door manually

- Viewing Window

- Glass Viewing Window on door

Shanghai Jiecheng DHG-9025AE vertical blower Drying Oven has a temperature control range of room temperature +10~300°C, tempered glass observation window on the door, and 2 cargo carriers (standard). In addition, the DHG-9025AE has a temperature resolution of 0.1°C and a fluctuation of ±0.1°C, with an input power of 800W.

Features

★ The inner tank is made of 304 stainless steel, which does not rust

★ Intelligent controller, good temperature control effect, a large number of exports to European countries

★ Digital one-screen display, temperature, time and other parameters

★ After-sales service is guaranteed, and after-sales service is available all over the country (except for townships)

★ Streamlined luxury machine shape with aesthetic design concept, electrostatic spraying box, and tempered glass observation window with large Viewing Angle on the door

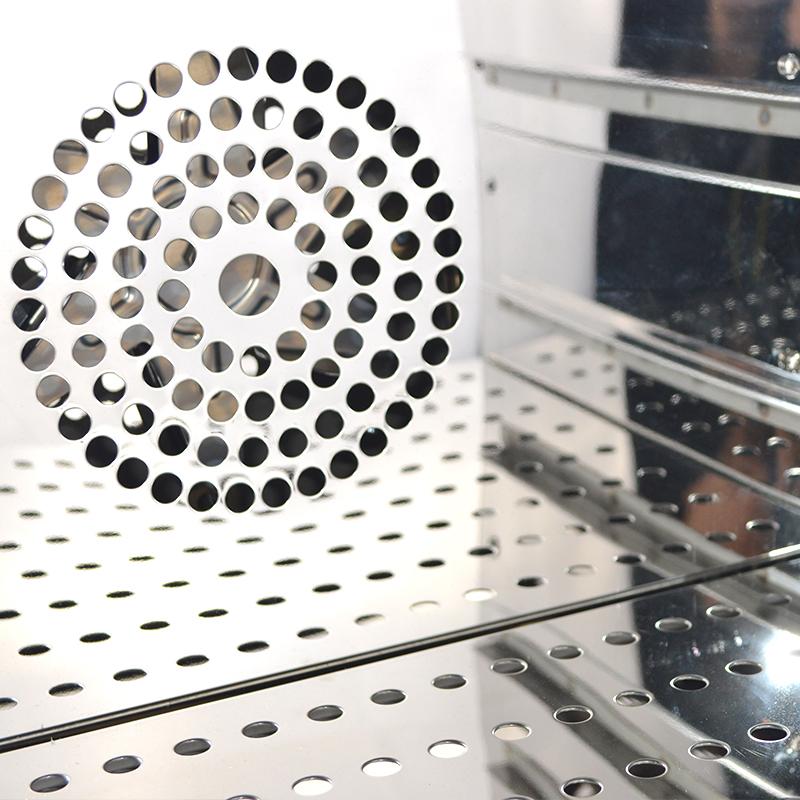

★ It is made of mirror stainless steel argon arc welding, and the box is made of good steel plate, which is beautiful and novel. Mirrored stainless steel lining, the instrument will never be corroded.

★The large LCD screen displays the set parameters and measured parameters

★ High-performance thermostatic function to avoid evaporation and drying of samples

★ The new synthetic silicon sealing strip is adopted, which can operate at high temperature for a long time, has a long service life and is easy to replace.

★ The hot air circulation system is composed of a fan that can operate continuously at high temperatures and a suitable air duct to improve the temperature uniformity in the working room.

★ The cargo carrier in the box can be adjusted freely

Introduction to controls

★ The microcomputer P.I.D. temperature controller with over-temperature deviation protection and digital display is adopted, with timing function, and the temperature control is accurate and reliable.

★ The upgraded version of the sound and light alarm environment scanning microcomputer chip has more powerful data processing functions

★ Functions such as over-temperature alarm, timed shutdown, call recovery, parameter encryption, temperature correction and so on.

★ With the function of power-off recovery, the equipment can automatically resume operation according to the original program after the external power supply suddenly loses power and the power comes again

The Type II Blower Drying Oven has the following upgrades over the Type I:

1. Partition upgrade (the partition is made of stainless steel plate punching, which can solve the unevenness of the previous grid when placing items)

2. Controller heat conduction plate (although the controller is convenient to operate at the top, the hot air will run up when the door is opened after use, affecting the control life, and the type II increases the heat conduction plate and can effectively protect the controller at the same time)

3. Improvement of air duct structure (redesign of strong convection air duct to significantly improve uniformity)

4. Door handle upgrade (upgraded snap door handle, simple and light to open and close the door)

5. Partition upgrade: (first use many partitions welded in the inner tank, put the partition on the box drawer type pull-out, type I Drying Oven is hook-type non-pullable)

6. Appearance upgrade (while completing the overall performance improvement of the equipment, the appearance upgrade is more exquisite and more atmospheric, and this series of products is also OEM for some dealers in Europe)

Introduction to controls

★ The microcomputer P.I.D. temperature controller with over-temperature deviation protection and digital display is adopted, with timing function, and the temperature control is accurate and reliable.

★ The upgraded version of the sound and light alarm environment scanning microcomputer chip has more powerful data processing functions

★ Functions such as over-temperature alarm, timed shutdown, call recovery, parameter encryption, temperature correction and so on.

★ With the function of power-off recovery, the equipment can automatically resume operation according to the original program after the external power supply suddenly loses power and the power comes again

Security settings

★ Thoughtful safety protection design realizes triple safety protection for personnel, samples and equipment

★ Safety functions: sensor fault alarm, over-temperature alarm, independent over-rise preventer, independent over-temperature protector, over-current trip protection, etc

Product display

- 1Coating film formation performance inspection method--paint (coating) film preparation

- 2Shanghai Jiecheng full series of box selection reference table [selection]

- 3DHG-9070A Blast Drying Oven operating instructions

- 4Summary of commonly used instrument types for film resistance testing

- 5How is Coating storage stability determined?

- 6Common faults of electric blast Drying Oven

陈晓雷 - 《锦州市计量检定测试所》

- 7Comparison of parameters of Yiheng BPG series blast Drying Oven

- 8Study on Wear Resistant Coating on Resin Surface

- 9Development of High Strength Polyurethane Waterproof Coatings for Railway

- 10How to measure film and film Drying time?

- 1GB/T 30435-2013《Electric gravity convection and forced ventilation ovens》

- 2GB/T 37193-2018《Optical functional films—Polyethylene terephthalate(PET) film—Determination of extraction rate》

- 3JB/T 5520-1991《Technical conditions for drying oven》

- 4GB/T 11026.5-2010《Electrical insulating materials - Thermal endurance properties - Part 5: Ageing ovens - Precision ovens for use up to 300℃》

- 5GB/T 21782.7-2008《Coating powders - Part 7:Determination of loss of mass on stoving》

- 6GB/T 16592-1996《Powder coating-Determination of loss mass on stoving》

DHG-9625AE

DHG-9625AE