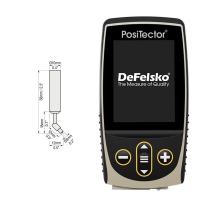

Defelsko PosiTector 6000 N45S3 Coating Thickness Gauge 45 ° micro probe

SEAdvanced eddy Current Coating Thickness Gauge, 45 ° miniature split probe for measurement of non-ferrous metal substrates, touch LCD screen, thickness measurement range 0~625μm, error +/- 1%, with calibrated certificate, suitable for measurement of small parts, difficult to contact areas.

$1804.00/set

PromotionLoading...

Coupon

Model:

Similar products

Defelsko PosiTector 6000 N45S3 Coating Thickness GaugeSPEC

Defelsko PosiTector 6000 N45S3 Coating Thickness GaugeDetails

Defelsko PosiTector 6000 N45S3 Coating Thickness GaugePacking list

- SKU

- NB001202

- Measurement principle

- Eddy Current

- Measurement range

- 0~625μm

- margin of error

- ±1%

- Resolution

- 0.1μm

- probe

- N45S3 Probe (45 ° Micro)

- statistical function

- Measurement times, MAX Maximum, MIN Minimum, Average, Standard deviation

- icon function

- Yes.

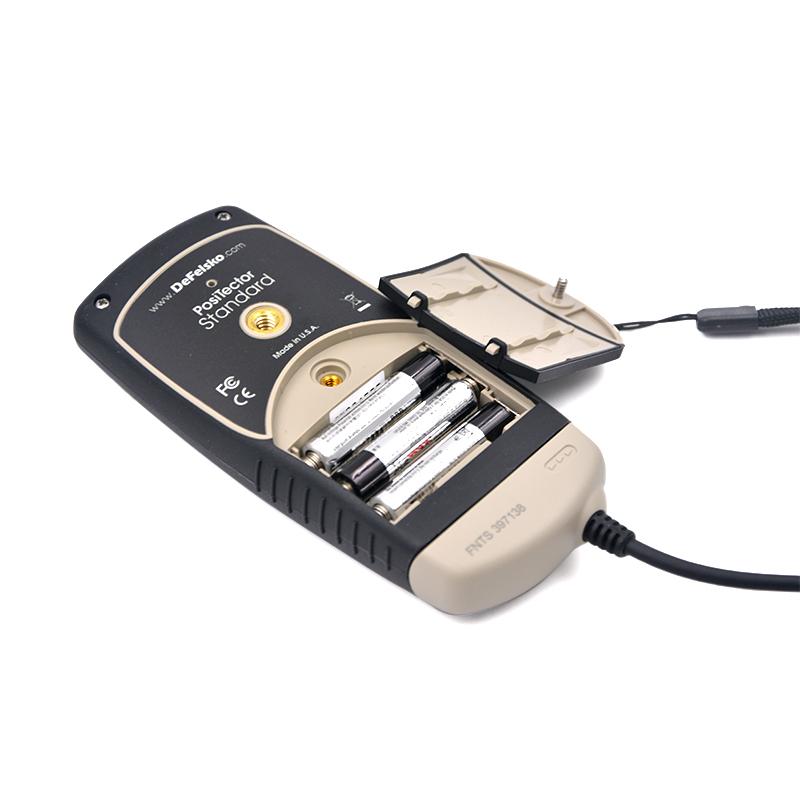

- Power Supply

- 3 * AAA alkaline battery

- Standards

- ISO 2178/2360/2808、PrEN ISO 19840、ASTM B499/D1186/D1400/D7091/E376/G12、BS3900-C5、SSPC-PA2等

- Calibrated Certificate

- Yes.

- Language

- Chinese, English

- Display screen

- 2.8-Inch color touchscreen

- Interface

- USB、Bluetooth

- supporting software

- PosiSoft Software Suite

- Machine Weight

- 137G (without battery)

- Machine size

- 127*66*25.4mm

- Data storage

- 250000 Measured values, 1000 groups

- Test environment

- Non-ferrous metal substrate nonconductive coating environment

- Defelsko calibrated standard

- STDA2

- screen image saving

- One hundred.

- Protection level

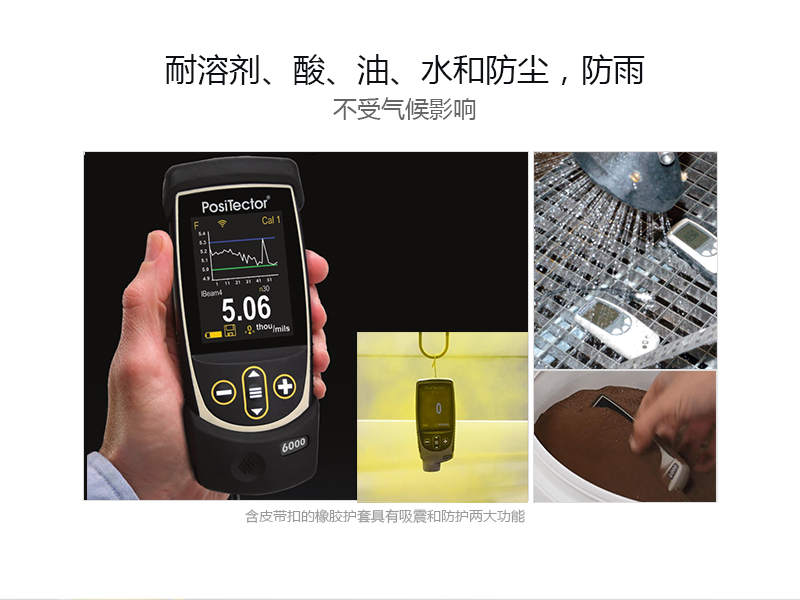

- IP65

- Measurement speed

- More than 180 readings per minute

PosiTector 6000 N45S3

Coating Thickness Gauge

Advanced eddy Current Coating Thickness Gauge, 45 ° miniature split probe for measurement of non-ferrous metal substrates, touch LCD screen, thickness measurement range 0~625μm, error +/- 1%, with calibrated certificate, suitable for measurement of small parts, difficult to contact areas.

Introduction

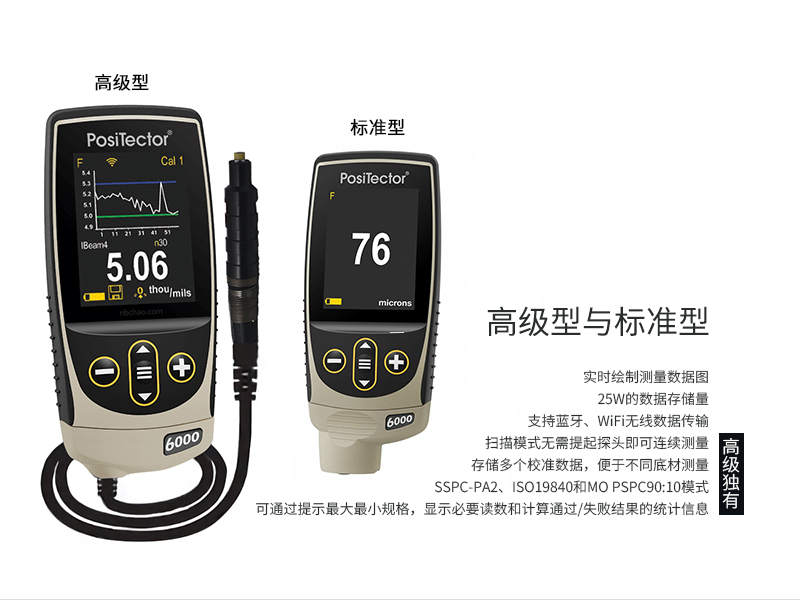

The Defelsko PosiTector 6000 N45S3 Coating Thickness Gauge is an advanced eddy current Thickness Gauge with a color high-contrast LCD display capable of displaying real-time graphics, storing up to 100,000 measurements, and providing continuous readings without lifting the probe.The PosiTector 6000 N45S3 Coated Thickness Gauge housing is IP65 rated for resistance to dust, water, and solvent acids, and the 45° miniature probe is abrasion resistant, making the tiny probe ideal for measurements in narrow coated areas.

Recommended reading

★《How do you choose the Defelsko PosiTector 6000 Coating Thickness Gauge?》

★Defelsko PosiTector 6000 Series Coating Thickness Gauge Details (Text Version)

FAQ

QDo the Defelsko 6000 series thickness gauges come standard with software?

A

This does not have a physical software CD, but PosiSoft software can be downloaded for free on the manufacturer's official website for downloading and viewing data reports.

QWhy can't the Defelsko Coating thickness gauge be charged?

A

Hello, there are two solutions: 1. It is equipped with 3 ordinary AA batteries, please open it and replace it; 2. It can also be connected to a computer for direct use, but it cannot be charged (powered by a USB cable).

QCan it be used for composite surface film testing? Carbon fiber composite substrate (such as paint coating of automotive plastic parts)

A

This model cannot test the coating thickness on plastic substrates, so the Defelsko 200 series is required

QDoes the Defelsko Coating thickness gauge meet the ISO 2360 standard?

A

The PosiTector 6000 N45S3 Coating thickness gauge can refer to

QWhat does F/N/FN mean in the model number?

A

F probe using magnetic principles to measure the film thickness of the non-magnetic coating on ferrous metals.

N probe using eddy current principle to measure the non-conductive coating on non-ferrous metals Film thickness.

The FN probe combines all the functions of the "F" and "N" probes.

Knowledge

- 1Principle and Application Analysis of Coating Thickness Gauge

- 2Explore the principle, application and selection of phosphating layer Coating Thickness Gauge

Standard

- 1ISO 《Non-magnetic metallic coatings on metallic and non-metallic basis materials — Measurement of coating thickness — Phase-sensitive eddycurrent method》

- 2JB/T 13939-2020《Nondestructive testing instruments.Eddy current thickness gauge》

- 3QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 4JJG 818-2018《Magnetic and Eddy Current M easuring I nstrument for Coating Thickness》

- 5GB/T 1727-2021《General methods for preparation of coating films》

- 6HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 7ASTM B244-2021《Standard Test Method for Measurement of Thickness of Anodic Coatings on Aluminum and of Other Nonconductive Coatings on Nonmagnetic Basis Metals with Eddy-Current Instruments》

- 8ISO 2360-2017《Non-conductive coatings on non-magnetic electrically conductive base metals — Measurement of coating thickness — Amplitude-sensitive eddy-current method》

- 9ASTM D7091-2022《Standard Practice for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied to Non-Ferrous Metals》

- 10ASTM E376-2019《Standard Practice for Measuring Coating Thickness by Magnetic-Field or Eddy Current (Electromagnetic) Testing Methods》

PosiTector 6000 N45S3

PosiTector 6000 N45S3