YUSHINDT YUT2600 Ultrasonic Flaw Detector, zero-point calibrated coating penetration free

yushindt YUT2600 Ultrasonic Flaw DetectorSPEC

yushindt YUT2600 Ultrasonic Flaw DetectorDetails

yushindt YUT2600 Ultrasonic Flaw DetectorPacking list

- SKU

- NB012034

- Frequency range

- 0.5~15MHz

- Speed of sound

- 1000~9999m/s

- Operating Mode

- Pulse echo, double crystal

- pulse shift

- 0~2000mm

- Probe zero

- 0-99.99us

- Gain range

- 0~110dB, (0.1, 1, 2, 6) dB steps

- Vertical Linearity

- ≤3%

- Horizontal Linearity

- ≤0.3%

- resolution

- ≥32dB

- Dynamic range

- ≥30dB

- Sensitivity margin

- ≥ 55dB (depth 200mm. flat bottom hole)

- Average electrical noise level

- ≤10%

- Operating Time

- > 8 hours

- Power Supply

- 12V DC,220V AC

- Dimension

- 270*190*60mm

- Weight

- 2Kg (including battery)

YUT2600 ultrasonic flaw Detector is a portable industrial non-destructive testing instrument, which can quickly, conveniently, without damage and accurately detect, locate, evaluate and diagnose a variety of defects (cracks, looseness, porosity, inclusions, etc.) inside the workpiece. It can be used both in the laboratory and in the engineering field.

Scope of application

It is suitable for all kinds of metal materials, all kinds of welded parts, forgings, castings, etc., and is widely used in the design stage, manufacturing process, finished product inspection, in-service inspection and other fields in boilers and pressure vessels, aerospace, electric power, petroleum, chemical industry, offshore oil, pipelines, military industry, shipbuilding, automobiles, machinery manufacturing, metallurgy, metal processing industry, steel structure, railway transportation, nuclear power, universities, road construction, dam construction, bridge construction and other fields.

Features

The full-screen display function allows the echo display area to cover the entire screen, giving workers a significant window experience

Solid waveform display, increase the visual contrast of the waveform, and it is not easy to miss the detection for fast scanning

Large-capacity memory for up to 1000 datasets, including waveforms, curves, parameters, etc. (including 1000 channels in the traditional sense)

Innovative high-energy lithium battery for computer notebooks

There are two operation interfaces in Chinese and English

The operation is simple, and the user can quickly grasp the use of the instrument

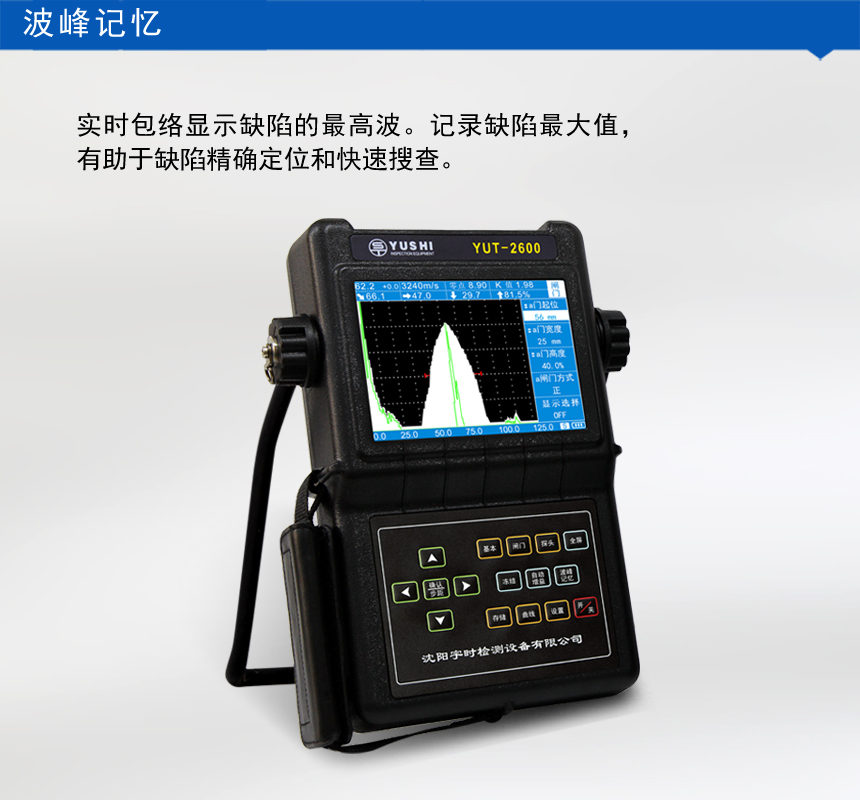

Peak memory: The real-time envelope displays the highest wave of the defect, records the maximum value of the defect, helps to accurately locate the defect and quickly scan, and can also characterize the defect with the help of the envelope waveform

Auto Gain: Automatically adjusts the gain to the set amplitude height

Alarm function: incoming/losing alarm

Real-Time Clock: Automatically records the date and time of the stored waveform

Display Freezing: Capture waveform and sound path data at any time, and move the gate to measure echo parameters after freezing

Defect location: real-time display of sound path S, level X, depth Y, wave height H

Digital rejection: 0-80%, in 1% increments, without affecting linearity and gain

Data communication: communicate with the computer through RS232 interface, transmit waveforms and data, and realize the management of flaw detection results and the generation and printout of flaw detection reports on the computer

2 independent measuring gates to monitor echo amplitude and sound path distance

During shear wave flaw detection, the depth of the second and third wave defects is automatically calculated according to the plate thickness

The perfect DAC curve function changes with the change of gain, sound path, and displacement

Adjustable brightness of the true color TFT LCD screen, with a variety of color schemes to choose freely

- 1Ultrasonic Flaw Detectors: the right-hand man for nondestructive detection

- 2Application of Ultrasonic Flaw Detector

- 3How to use ultrasonic Flaw Detector for rail flaw detection?

- 4What factors determine the sensitivity of ultrasonic Flaw Detector?

- 5Application of Ultrasonic Nondestructive Testing in Steel Structure Identification and Testing

- 6Method for calibrating ultrasonic straight probe, dual crystal probe and oblique probe

- 7Ultrasonic Thickness Gauge FAQ and solution

- 8Analysis of the Method of Detecting Steel Castings with Ultrasonic Flaw Detector

- 9How does Ultrasonic Thickness Gauge pass through the coating measurement Film thickness?

- 10Detailed explanation of commonly used ultrasonic flaw detection methods

YUT2600

YUT2600