YUSHINDT LM300 Leeb Hardness Tester pen OLED screen

LM300 Leeb Hardness Tester light and small, OLED high definition color screen can replace imported written test Hardness Tester, easy to operate

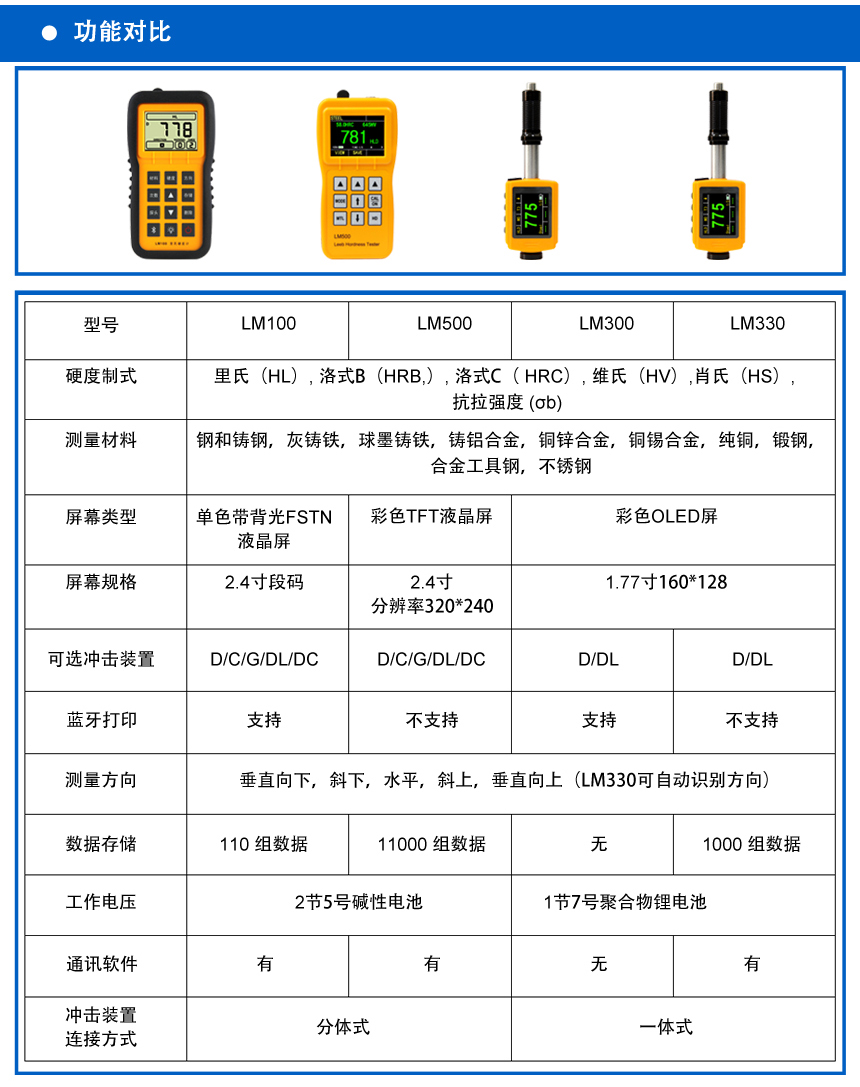

Model:

yushindt

yushindt LM300 Leeb Hardness TesterSPEC

yushindt LM300 Leeb Hardness TesterDetails

yushindt LM300 Leeb Hardness TesterPacking list

- SKU

- NB012043

- Hardness system

- HL/HRC/HRB/HB/HV/HS/σb

- Measurement range

- 200~960HLD、19.8~68.5HRC、13.5~100HRB、30~651HB、80~976HV、26.4~99.5HS、375~2639σb

- Impact device

- Type D, replaceable DL probe

- Error of indication

- ≤6HLD(HLD=800)

- Measurement direction

- Support vertical down, diagonal down, horizontal, diagonal up, vertical up

- Measurement material

- Steel and cast steel, stainless steel, gray cast iron, ductile cast iron, cast aluminum alloy, copper zinc alloy, copper tin alloy, pure copper

- Resolution

- 1HL,1HV,1HB,0.1HRB,0.1HRC,0.1HS

- Display

- 1.77 inch (resolution 160X128) color OLED display

- Communication interface

- USB port for charging or data transfer

- Power Supply

- No. 7 polymer lithium battery, Voltage 3.7V, Capacity 900mAh; when the power is insufficient, there is a low Voltage prompt

- Operating temperature

- -10~+50℃

- Dimensions

- 150 * 46 * mm (using D-type Impact device), 204 * 46 * 23mm (using DL-type Impact device)

- Weight

- 110G (using D-type Impact device), 125g (using DL-type Impact device)

- meet the standard

- GB/T 17394-1998,ASTM A956

- Adjustment

- Users can calibrate themselves

- working language

- Available in Chinese, English, Traditional Chinese, Spanish, Japanese

- Indication Repeatability

- <6HLD(HLD=800)

LM300

Leeb Hardness Tester

LM300 Leeb Hardness Tester is light and small, and the OLED high-definition color screen can replace the imported written test Hardness Tester, which is easy to operate.

It is suitable for failure analysis of installed mechanical or long-term tissue parts, abrasive cavities, heavy workpieces, pressure vessels, other equipment of automobile generator set machines, narrow test areas, production lines of bearings and other parts, material differentiation of metal material warehouses and on-site hardness testing of large workpieces, and batch testing of workpieces on the production line. It is also widely used in metal manufacturing, transportation, power plants, petrochemicals, aviation, construction and laboratories.

FAQ

QIs the price listed on the website the final cost for overseas purchases?

ANo, it isn't. This is the ex-factory price of the product in the Chinese Mainland. In addition to this price, buyers from different countries need to account for additional costs such as shipping fees, tariffs, and others. For specific regional quotes, please consult our customer service or fill out a quotation form.

QWhat is the specific process for purchasing the product?

AFirst, please click on the quotation form on the website and fill in detailed information. Our customer service personnel will then send you a quotation based on your specific country and region, confirming payment and delivery methods. Following this, we proceed with contract signing, payment, and shipment. You can then await delivery.

QWhat should I do if the instrument I purchase needs repair?

AAfter-sales repair for overseas instruments is an unavoidable issue. Our repair terms stipulate that the sender is responsible for the shipping and insurance costs incurred for the repair. Repairs within the warranty period are free, while repair costs beyond the warranty period are determined based on the actual situation.

Knowledge

LM300

LM300