Furnace temperature tracker TCK-1206 DAQTECH 6 test channel K type Thermocouple

SEDAQTECH TCK-1206 Furnace temperature trackerSPEC

DAQTECH TCK-1206 Furnace temperature trackerDetails

DAQTECH TCK-1206 Furnace temperature trackerPacking list

- SKU

- NB001226

- Number of channels

- 6

- Probe Type

- K type

- temperature Measurement Range

- 0~1000℃

- temperature measurement Accuracy

- ±1.2℃

- Sampling interval

- 0.25-600 seconds, software settings

- resolution

- 0.1 ℃ (full scale)

- Storage Capacity

- 80000 points/channel

- Total power

- ≤100mW

- Power

- 3.6VDC (built-in rechargeable battery)

- Connectivity

- RS-232 或 USB / RF

- Recorder size

- 196*103*21mm

- Insulation box size

- 250*133*30mm

- Test stand size

- 268(W)×296(L)mm

- wingspan width

- 145-268mm (std.)

- Analysis software

- ProfileManager V1.50

Introduction

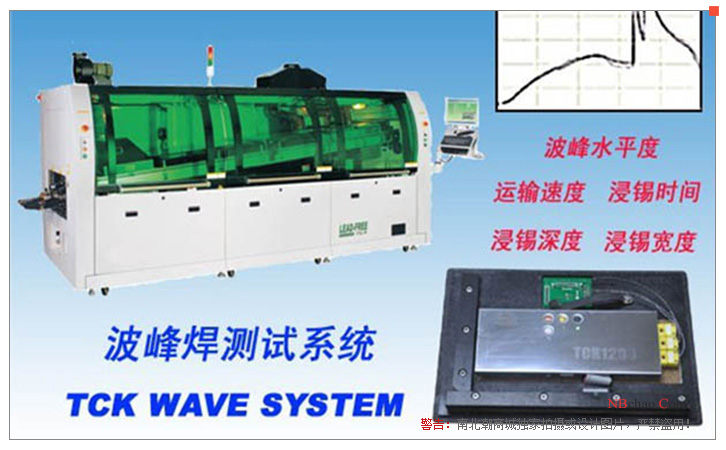

Dafengke TCK-1206 furnace temperature tracker is a professional wave soldering furnace temperature Tester designed for DIP users. It is a 6 test channel furnace temperature Tester. It uses a K-type thermocouple with good linearity and high sensitivity. The wave soldering furnace temperature test system is composed of TCK system temperature measuring instrument and W-1 wave soldering test frame. TCK-1206 Furnace Temperature Tracker can not only test the furnace temperature curve, but also measure the dipping depth, wave crest level, tin wave height, transportation speed, dipping time and dipping width. The furnace temperature tracker is powerful and easy to use.

Features

TCK-1206 furnace temperature tracker has 8 kinds of test functions, as follows:

1. Test the peak level function

2. Test tin wave height function

3. Test the tin immersion depth function

4. Test equipment chain speed function

5. Test the immersion tin width function

6. Test the dipping time function

7. Test the slope function of the preheating zone

8. Test the maximum temperature function of the preheating zone

Wave soldering temperature curve analysis function

1. Set the temperature and transportation speed in the temperature zone of the reflow furnace and the wave peak furnace

2. Name of temperature sampling point and PCB diagram

3. Time and slope between any two temperature values

4. The slope between any two time points

5. The time beyond the specified temperature

6. Maximum temperature and temperature at any point in time

7. Horizontal temperature line, vertical time line and the time between the two times

8. Mesh editing refinement and curve zoom display

9. Simulation curve function, process optimization, test date and time

10. Input of company name, product name and remarks

11. Select the printing direction (landscape printing and portrait printing)

12. The temperature data report can be exported to Excel for editing

13. Insert picture function to make the position of temperature test point clear at a glance

14. Call multiple sets of temperature curves for comparison

15. Two Operating Modes of real-time monitoring and instrument recording

16. Manually clear and software clear instrument memory data methods

17. Three starting modes: manual, specified time and specified temperature

18. Product database management, equipment database management, solder paste database management

19. Analysis of PWI process index

Pictures