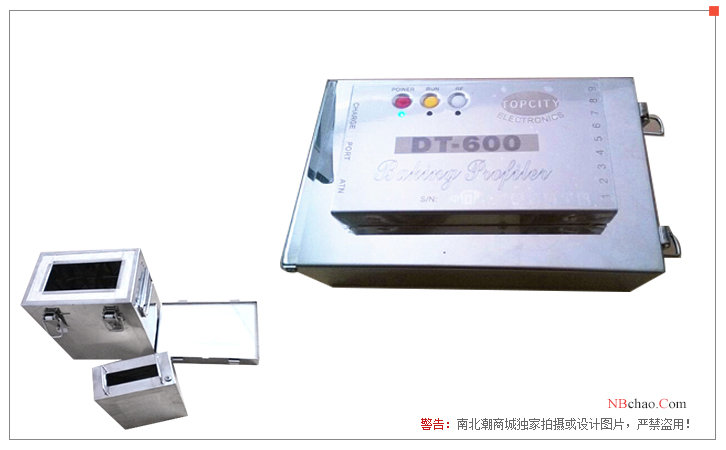

Furnace temperature tracker DT-600 DAQTECH 4/6/9 test channel, oven/tunnel furnace/oven temperature tracking

SEDAQTECH DT-600 Furnace temperature trackerSPEC

DAQTECH DT-600 Furnace temperature trackerDetails

DAQTECH DT-600 Furnace temperature trackerPacking list

- SKU

- NB001230

- Number of channels

- 4/6/9

- Probe Type

- K type

- temperature Measurement Range

- 0~1000℃

- temperature measurement Accuracy

- ±(0.1%+1℃)

- Sampling interval

- 0.25-600 seconds, software settings

- resolution

- 0.1 ℃ (full scale)

- Storage Capacity

- 80000 points/channel

- Total power

- ≤100mW

- Power

- 3.6VDC (built-in rechargeable battery)

- Connectivity

- RS-232 /USB /RF

- Recorder size

- 135*80*19mm

- Insulation box size

- 250*100*30mm

- Analysis software

- Baking-Profiling Chinese and English languages

Introduction

Dafengke DT-600 furnace temperature tracker is a four-, six-, nine-channel professional furnace temperature profiler, using K-type thermocouples, the temperature measurement range is 0~1000 degrees Celsius, and can store 20 sets of data. 232, USB, RF various communication ports to connect PC operation data. DT-600 furnace temperature tracker is a domestic (CN) professional furnace temperature tracker for ovens, tunnel furnaces, and ovens. It has professional hardware and software design, and provides accurate and effective furnace temperature curve testing and analysis to users.

Applications

Dafengke DT-600 furnace temperature tracker is suitable for high-temperature ovens for baking processes such as automotive coating, powder coating, non-stick coating, mobile phone screen, food processing, chemical industry, glue curing, metal plating and baking paint.

Temperature curve analysis setting function

1. Set the temperature and transportation speed of the oven temperature zone

2. The name of the temperature sampling point and the schematic diagram of the workpiece

3. The time between any two temperature values

4. The slope between any two temperature values

5. Time beyond the specified temperature and arrival time

6. Maximum temperature and arrival time

7. Horizontal temperature line, vertical time line and the time between the two times

8. Mesh editing refinement and curve zoom display

9. Test date and time

10. Two Operating Modes of real-time monitoring and DT-600 furnace temperature tracker recording

11. Input of company name, product name and remarks

12. Select the printing direction (landscape printing and portrait printing)

13. The temperature data report can be exported to Excel for editing

14. Insert picture function to make the position of temperature test point clear at a glance

15. Call multiple sets of temperature curves for comparison

16. Manual clearing and software clearing DT-600 furnace temperature tracker memory data method

17. Three starting modes: manual, specified time and specified temperature

Pictures