QHY Buchholz Indentation Tester for paint/Varnish coating indentation test

RongJiDa QHY Buchholz Indentation TesterSPEC

RongJiDa QHY Buchholz Indentation TesterDetails

RongJiDa QHY Buchholz Indentation TesterPacking list

- SKU

- NB001233

- Standards

- GB/T9725-88、ISO1518-73、DIN53153

- Indentation device Weight

- 1Kg±5g

- Indentation load

- 500±5g

- Indentation reading Accuracy

- 0.1mm

Introduction

Rongjida QHY Buckholz indentation Tester is a testing instrument for measuring the hardness of paint film coatings. The indentation length is formed by applying pressure on the surface of the coating film, and the compression resistance is expressed as a function of the reciprocal of the indentation length. The hardness of the paint film can be determined based on the results of the trace test. When the indentation resistance of the coating film increases, the indentation resistance value increases. QHY Buckholtz indentation Tester is produced in strict accordance with GB/T9725-88, ISO1518-73 and DIN53153. It is reliable in quality and can accurately measure the hardness of paint coatings.

Applications

QHY Buckholtz indentation Tester is only suitable for measuring the pressure resistance of the plastically deformed paint film surface. For indentation testing of single-coat or multi-layer coatings of paints and varnishes.

product structure

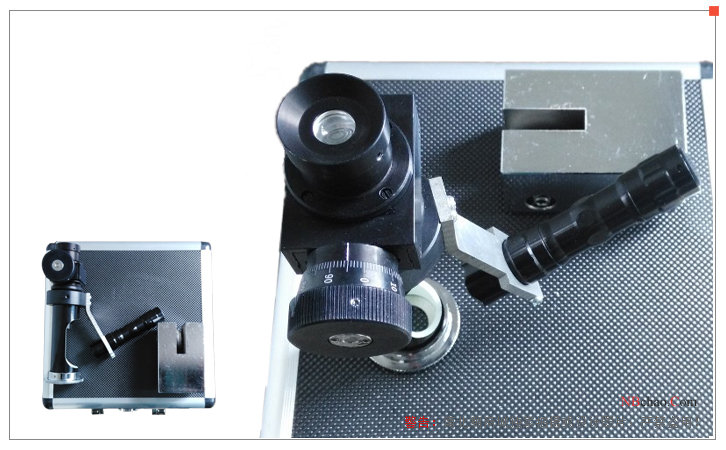

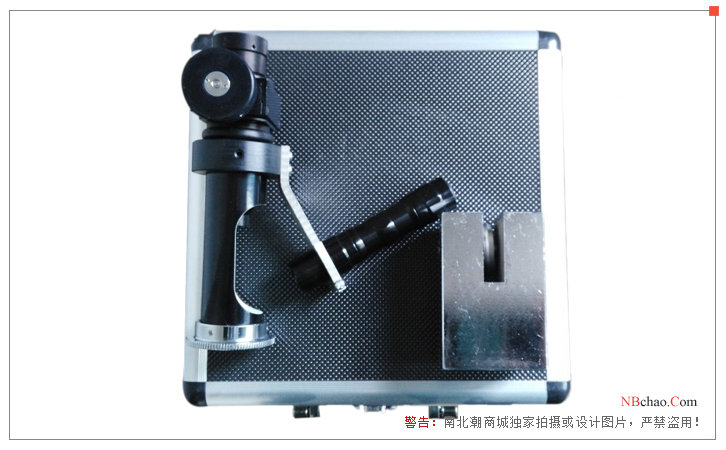

1. Measuring device

The measuring device of the QHY Buckholtz indentation Tester is a 20x reading microscope with an illumination greater than 60° to generate an image on the length of the indentation.

1) Light source 2) Microscope 3) Indentation 4) Paint film 5) Test board 6) Image

2. Indentation device

The indentation device of the QHY Buckholtz indentation Tester is composed of a rectangular metal block, a hard tool steel metal wheel with a sharp blade, and two pointed feet.

Pictures

Operation experiment

1. Experimental requirements

a. On a hard, flat, undistorted substrate with no visible bumps on the surface;

b. Under the test load, the substrate should not be deformed;

c. During the test, the paint film generally exhibits plastic deformation instead of elastic deformation;

d. Under the load of the indentation device, the film thickness of the paint film still maintains a thickness of at least 10um;

e. The paint film should be uniform, smooth and clean.

2. Sampling shall be carried out according to the standard GB3186.

3. The test panel is made according to the requirements of item 5 in the standard GB9275-88.

4. Experimental environment: under the conditions of temperature 23±2°C and Relative Humidity (50±5)%.

2. Specific operation steps

a. Put the paint film of the test panel upwards and place it on a stable test bench plane;

b. Gently place the QHY indenter of the Buckholtz indentation Tester on the appropriate position of the test plate; when placing it, firstly make the feet of the device touch the test plate, and then carefully put down the Buckholtz indentation Tester indenter. You can mark the position of the test indentation first, so that you can find the indentation again after pressing. When picking up the device and leaving the test panel after placing it for 30±1s, the indenter should be used first, followed by the feet of the device.

c. Unless otherwise specified, within 35±5s after the indenter of the Buckholz indentation Tester is removed , place the microscope on the measurement position, and express the image length of the indentation in millimeters. Accurate to 0.1mm, record the result.

d. Carry out 5 tests on different parts of the same test plate, and calculate the arithmetic mean value.

3. Calculation method

a. Round off the average number to the value in a certain column in the table, and use the rounded value of the indentation length to look up the table to obtain the indentation resistance.

b. Calculate the indentation resistance by the following formula: 100/L Chinese formula: L—indentation length mm

- 1What is an indentation peel test?

- 2What is the Buchholz indentation test?

- 3Buchholz Indentation Hardness Tester and its test program

- 4[Film Properties and Measurements] - Determination of film hardness

- 5How to measure film hardness

- 6Buchholz indentation test: an important method for measuring film hardness

- 7Test principle of paint film indentation hardness

- 8How does the Barkholz indentation Tester determine the indentation hardness of paint films?

- 9Test coating Hardness with Buchholz Indentation Tester

- 10Detailed explanation of several coating Hardness detection methods

- 1ASTM D3794-2022《Standard Guide for Testing Coil Coatings》

- 2ISO 1520-2006《Paints And Varnishes - Cupping Test》

- 3ASTM D1474-2018《Hardness of organic coatings indentation 》

- 4ISO 2815-2003《Paints and varnishes Buchholz indentation test》

- 5ISO 1518-1992《Paints and varnish scratch test》

- 6GB/T 9275-2008《Paints and varnishes Buchholz indentation test》

QHY

QHY