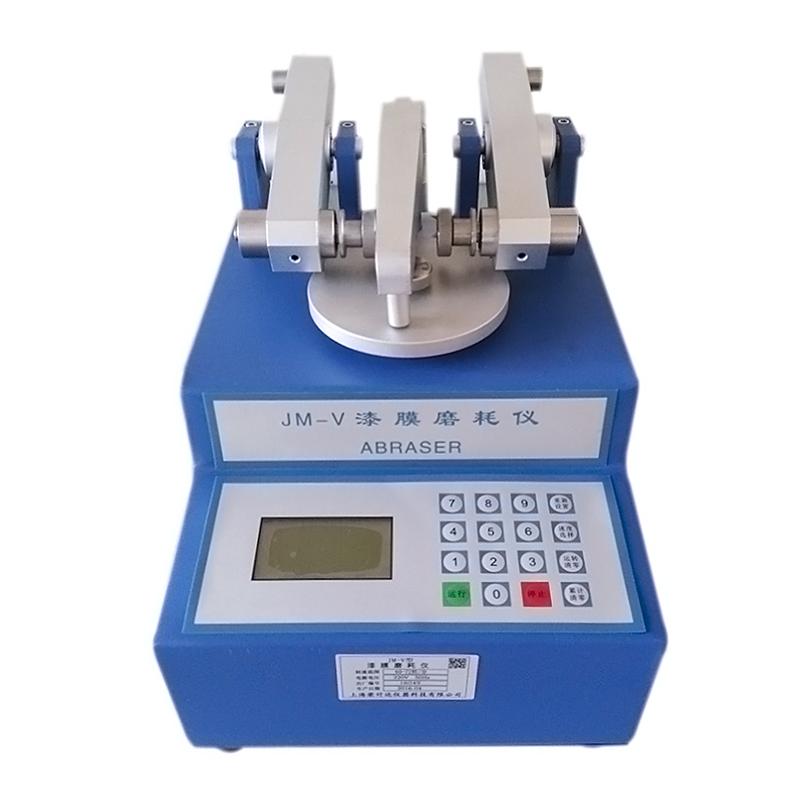

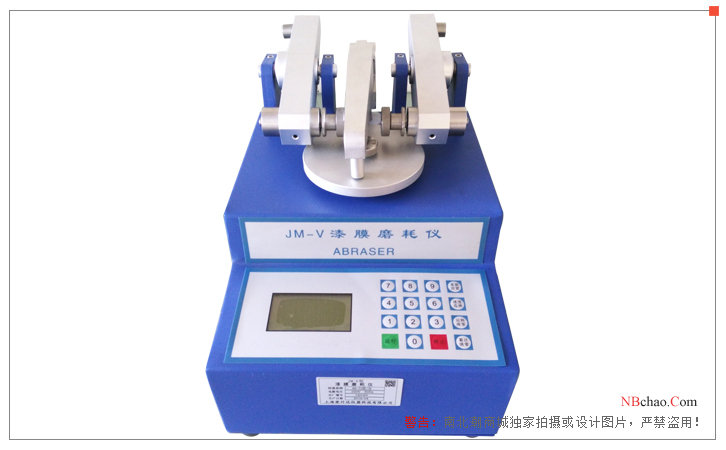

Paint film abrasion instrument JM-V RONGJIDA Coating paints wood dual-use wear performance testing

-

JINGKELIAN JM-VI abrasion instrument, film wear resistance performance test$ 1399.00SE

JINGKELIAN JM-VI abrasion instrument, film wear resistance performance test$ 1399.00SE -

MODERNER JM-V abrasion instrument (film configuration) is suitable for wear performance testing of Coating, paper, plastic, Spinning & weaving products

MODERNER JM-V abrasion instrument (film configuration) is suitable for wear performance testing of Coating, paper, plastic, Spinning & weaving products -

JINGKELIAN JM-VI abrasion instrument, wood wear performance test$ 1575.00SE

JINGKELIAN JM-VI abrasion instrument, wood wear performance test$ 1575.00SE -

Huida HD-2036 Wear Tester Load 250/500/1000g$ 1481.00SE

Huida HD-2036 Wear Tester Load 250/500/1000g$ 1481.00SE

RongJiDa JM-V Paint film abrasion instrumentSPEC

RongJiDa JM-V Paint film abrasion instrumentDetails

RongJiDa JM-V Paint film abrasion instrumentPacking list

- SKU

- NB001237

- Stepper motor parameters

- 2.5A 21kgcm

- Rotation speed of turntable

- 60/70/min

- Abrasive wheels size

- Φ51.4×12.7mm

- Load Weight Actual Weight

- Paint film 250/500/750/Wood 250g

- Load Weight label Weight

- Paint film 500/750/1000/Wood 500g

- Abrasive wheels equilibrating Weight

- Paint film 1/2/5/10/20g/wood 1/2/5g

- Dimensions

- 220×280×254mm

- Weight

- 13kg

Introduction

JM-V paint film abrasion Tester is a required instrument for wear resistance testing test, yesRongjida is manufactured in strict accordance with the GB/T1768-2006 standard for the test parameters of the wear resistance of the paint film, and also refers to the parameters of the wear resistance test of the material itself specified in the GB/T17657 standard, and is equipped with different turntable components and wear wheels for paint film and wood detection, which is a dual-purpose Detector.JM-V paint film abrasIon Meter is driven by stepper motor, which avoids the speed change caused by power grid Voltage fluctuations, and displays the working parameters and status of the abrasIon Meter through the LCD screen, which is accurate and reliable, and has the advantages of simple operation, flexible and convenient use, and reliable performance.

Applications

JM-V paint film abrasion Tester is suitable for laboratory testing the wear resistance of various coatings and paints, such as deck paint, floor paint, road paint, etc., and can also be used for testing the wear resistance of paper, plastics, textiles, decorative boards, etc.

Features

1. Driven by stepper motor, it avoids the speed change caused by power grid Voltage fluctuations, and the detection performance is reliable and stable.

2. Programmable control, high-resolution LCD screen.

3、JM-V Paint Film Abrasion TesterIt has the functions of information breakpoint protection and fault query.

4. It has a wide range of applications, such as coatings, paints, paper plastics, textiles, etc.

Meets standards

JM-V paint film abrasion Tester complies withGB/T1768-2006、GB/T17657、GB/T15036.2, GB/T15102, GB/T18102, GB/T4893.8, ISO7784.2 and other standards.

Operating Principle

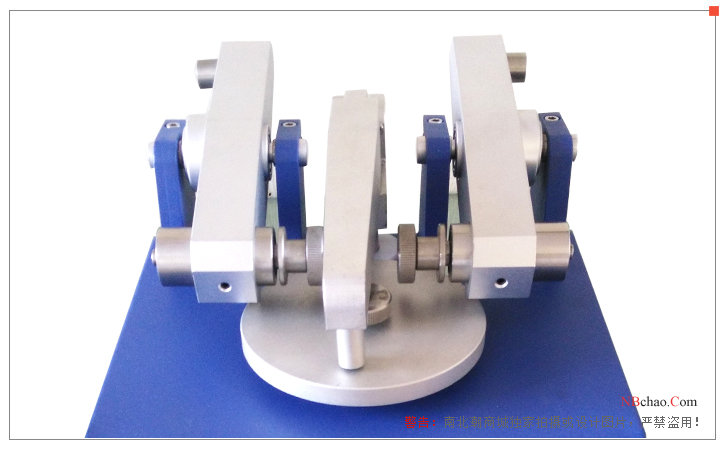

The JM-V paint film abrasion Tester is to contact two abrasive grinding wheels at a certain distance from each other with the specimen sample installed on the horizontal turntable, and make the central axis of the second grinding wheel and the central axis of the turntable not in the same plane. When the turntable rotates, a grinding wheel on the left produces friction from the outside to the center of the sample surface, while a wear wheel on the right produces friction from the center of the template surface to the outside. When the turntable rotates continuously, a series of intersecting circular friction marks in the form of a network form are formed on the surface of the template. This abrasion arrangement is adopted, so that the surface of the sample is rubbed in all directions, and the friction of the abrasIon Meter that reciprocates in one direction is avoided, and the friction has obvious directional defects, so that the abrasion evaluation is more objective.

Actual picture of the product

How to use:

1. Preparation before start-up:

(1) Correct the horizontal position of the JM-V paint film abrasIon Meter, the switch should be in the "off" position, and then plug in the power supply. Note: The ground terminal on the power outlet needs to be connected to the ground wire.

(2) Plug in the vacuum cleaner plug, insert the hose jokingly called it into the vacuum cleaner interface on the left side of the JM-V paint film abrasIon Meter, and adjust the height of the vacuum pipe (loosen the bolt on the back of the main unit), so that the vacuum nozzle is 1~2mm away from the surface of the template, and tighten the bolt after adjustment.

(3) When installing the grinding wheel, you need to unscrew the grinding wheel fixing nut first, wipe the dust on the shaft, and then install the grinding wheel that meets the requirements and tighten the nut.

(4) Install the required load weights at the front end of the pressurized arm.

(5) When placing the test sample, first unscrew the nut on the turntable, take out the washer, install the test plate, put in the washer and tighten the nut, and then gently put down the pressure arm and put down the suction pipe at the same time.

(6) Add a balance weight to the pin at the end of the pressurized arm:

Weight of balance weight = weight of grinding wheel - weight of pin 20g

For example, if the weight of the grinding wheel is 28g, a balance weight of 8g is added (the pin is fixed on the JM-V paint film abrasion Tester)

2. Operation of paint film abrasIon Meter:

(1) When the power switch is turned on, the buzzer makes a "beep" sound, which means that the JM-V paint film abrasIon Meter is working normally.

(2) Then display "Welcome to use, thank you for your cooperation" on the LCD screen.

(3) Then the LCD screen enters the operation interface to display:

"Operating speed: 60r/min"

"Set Laps: 0000 "

"Laps: 0000 "

"Cumulative Count: 00 "

JM-V Paint Film Abrasion TesterThe default speed is 60r/min, if you want to adjust the running speed to 70r/min, you just need to press the "speed selection" button. If you press the button again, the running speed returns to 60r/min

(4) The number keys on the button correspond to the number of 1,000 digits of the set number of laps. Each digit of the input buzzer will emit a "beep" sound, indicating that the input is valid, otherwise it means invalid. If you find that the input number is incorrect, please press the "Set Zero" button, and the number after "Set Laps" will be canceled immediately. If you confirm that the input is correct, please press the "Run" button, at this time the turntable will run immediately, and the "number of running revolutions" will automatically add 1 for each rotation. At this time, the buzzer emits an alarm sound of "Di Di Di", and the "cumulative times" will automatically add 1. This method of counting is particularly suitable for repeated operation of the abrasIon Meter over multiple cycles. For example, if there are 15 cycles of 500 revolutions, as long as "15" is displayed in the "number of revolutions", it means that 15 cycles have been rotated according to the "set number of revolutions", and there is no need to count them manually.

(5) "Set to zero", "Reset the number of laps", and "Clear the number of times" can clear the numbers in the "Set number of laps", "Number of laps", and "Number of revolutions" respectively. If you press the "Stop" button once during operation, the turntable will stop immediately. The original number and the number of laps that have been run are retained. To continue working, simply press the "Run" button and the JM-V abrasIon Meter will continue to run until the number of revolutions is set.

Precautions for use

(1) After use, cut off the power supply first, then clean the JM-V paint film abrasIon Meter, and cover the JM-V paint film wear Tester.

(2) If it is not used for a long time, the grinding wheel should be removed and put away.

(3) JM-V paint film abrasIon Meter needs to be overhauled and refueled once every year to two years

- 1Abrasion resistance, what is abrasion resistance?

- 2Determination of abrasion resistance of paint film

- 3Determination of leather colour fastness by swirl/spin friction Tester

- 4New elasticity Wooden ground floor film wear resistance test

孙伟圣;姜俊;沈斌华;徐立;陈明贵 - 《木材工业》

- 5Three effective tests for washable, brush & Wear testing machines

- 6What is the main role of talc in coating powder?

- 7Film abrasion resistance test

郑顺兴 - 《涂料与涂装科学技术基础》

- 8How is paint film abrasion resistance measured?

- 9Film performance testing summary

- 10What should be paid attention to in abrasion test?

- 1GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 2HG/T 3829-2006《Floor coatings》

- 3GB/T 13448-2006《Test methods for Prepainted Steel Sheet》

- 4GB/T 1768-2006《Paints and varnishes - Determination of resistance to abrasion - Rotating abrasive rubber wheel method》

- 5GB/T 4893.8-2013《Test of surface coatings of furniture - Part 8:Determination of wearability》

- 6GB/T 4893.8-1985《Furn iture-Methods of test for surface coatings》

- 7GB/T 9261-2008《Deck paint》

JM-V

JM-V