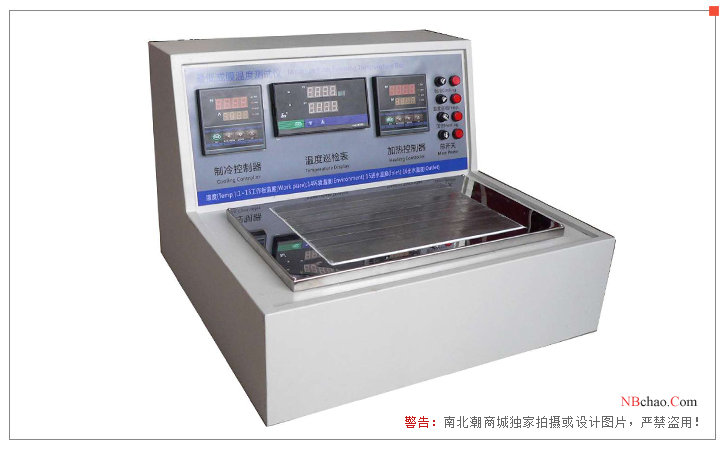

Minimum film forming temperature (MFFT) QMB RONGJIDA Determination of polymer emulsion minimum film forming temperature (MFFT)

RongJiDa QMB Minimum film forming temperature (MFFT) MeterSPEC

RongJiDa QMB Minimum film forming temperature (MFFT) MeterDetails

RongJiDa QMB Minimum film forming temperature (MFFT) MeterPacking list

- SKU

- NB001241

- Layered plate Operating temperature range

- 0~+45℃

- Temperature measurement point

- 10 point

- Temperature measurement Accuracy

- ±0.2℃

- Layer spacing

- 5 ℃±1 ℃

- Temperature measurement method

- digital display

Introduction

Rongjida QMB minimum film-forming temperature Tester is a domestic (CN) better detection instrument for determining the minimum film-forming temperature of polymer emulsion, with a simple, intuitive and accurate point, designed and manufactured according to the standard GB/T9267 and ISO2115-76 standards, the temperature control range is 0~45 degrees Celsius, and the test results are displayed digitally, which is widely used in coatings, adhesives, chemical fiber fabrics, leather, and paper.

Applications

QMB Minimum Film Forming Temperature TesterIt is used to determine the minimum film-forming temperature of polymer emulsions, such as when polymer emulsions are used as surface treatment agents such as coatings, adhesives, chemical fiber fabrics, leather, and paper.

Operating Principle

The working principle of QMB minimum film forming temperature Tester is to set up a refrigeration source and a heating source on a suitable metal plate, and keep it at the constant temperature point of its set temperature, and generate different temperature gradients on the metal plate through the principle of metal heat conduction. A uniform thickness of sample is coated on this temperature gradient plate, and the sample is evaporated by the temperature on the gradient plate to form a film. The phenomenon of film formation in the sample varies due to the temperature on the gradient plate. Find the dividing line part of the MFT temperature for that sample.

Minimum film formation temperature definition

The minimum film-forming temperature of polymer emulsion refers to the limit temperature when the polymer emulsion or latex paint is applied to the metal plate, and after the water evaporates, the polymer particles interact to form a continuous transparent film, referred to as the MFT temperature.

Actual picture of the product

- 1Minimum film forming temperature (MFFT): from theory to practice

- 2What is the minimum film formation temperature?

- 3What is the minimum film formation temperature?

- 4What is the minimum film formation temperature? How to reduce MFT

- 5How to understand the minimum film forming temperature of emulsion?

- 1HG/T 4448-2012《Textile dyeing and finishing auxiliaries.Determination of minimum film-forming temperature of polymer emulsion》

- 2GB/T 20623-2006《Emulsions for architectural coatings》

- 3GB/T 9267-2008《Emulsions for coatings and polymer dispersions for coatings and plastics - Determination of white point temperature and minimum film-forming temperature》

- 4GB/T 11175-2002《Testing methods for synthetic resin emulsions》

- 5ISO 2115-1996《Plastics - Polymer Dispersions - Determination Of White Point Temperature And Minimum Film-Forming Temperature》

- 6GB/T 9267-1988《Determination of emulsion minimum film forming temperature (MFFT) for latex paints》

QMB

QMB