TQC VF2073 Immersion Viscosity Cup with calibrated certificate 4mm filter

TQC sheen VF2073+Certificate Viscosity cupSPEC

TQC sheen VF2073+Certificate Viscosity cupDetails

TQC sheen VF2073+Certificate Viscosity cupPacking list

- SKU

- NB012536

- Viscosity range

- 96~683cSt

- outflow time

- 25~150s

- flow hole diameter

- 4mm

- Cup height

- 74mm

- Maximum width

- 63mm

- Total height

- 250mm

- Cup body material

- Titanium anodic oxidation aluminum

- Filter material

- stainless steel

- Handle material

- Titanium anodic oxidation aluminum

- Applicable standards

- Approximate DIN 53211

- Certificate

- With Certificate

- Weight

- 176~179g

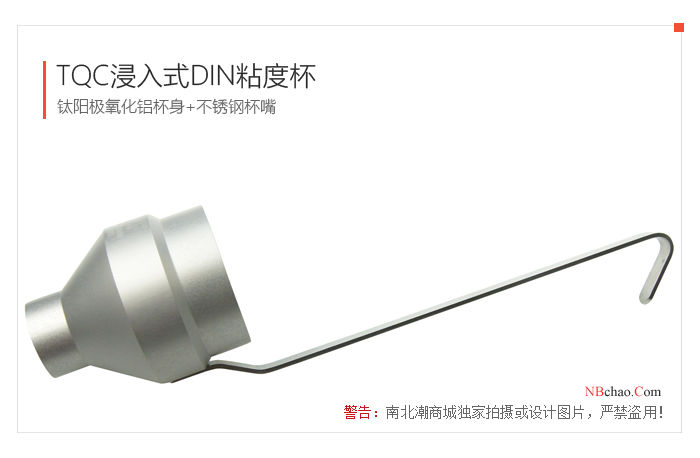

TQC immersion Viscosity CupIntroduction

TQC immersion Viscosity Cup is a kind of Viscosity Cup is designed with a long handle on one side of the Viscosity Cup, it is very convenient to measure the viscosity of the coating, just need to carry the Viscosity Cup into the paint with one hand, fill it with the paint, lift it to measure the viscosity value, you can control the viscosity value determination well, and the accuracy is high. This TQC immersion Viscosity Cup is made of aluminum alloy, and the filter is made of stainless steel. TQC dipstyleViscosity cups are suitable for viscosity testing of most coatings.

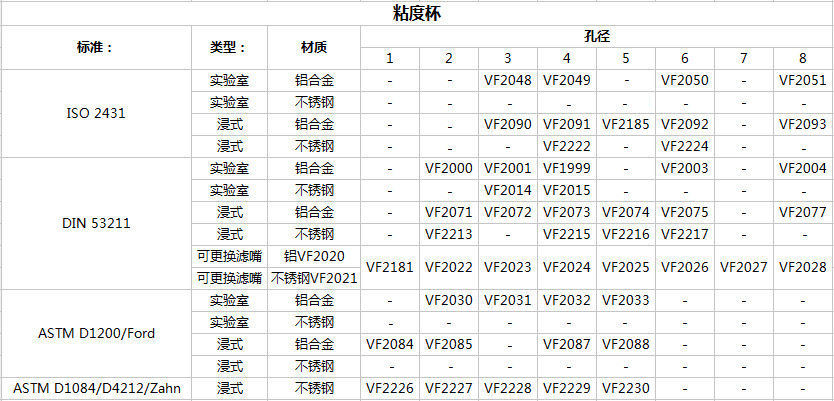

rootThe TQC immersion Viscosity Cups are available in VF2071, VF2072, VF2073, VF2074, VF2075 and VF2077 with different filter diameters. The TQC immersion Viscosity Cup complies with DIN 53211 and is suitable for detecting viscosity values in coatings, inks and other industries.

How to use:

1) According to the standard, the temperature of the liquid to be measured is 23 degrees Celsius, and the temperature fluctuation needs to be minimized and cannot exceed +/- 0.2 degrees Celsius during the test.

2) Adjust the temperature of the liquid to be measured if necessary.

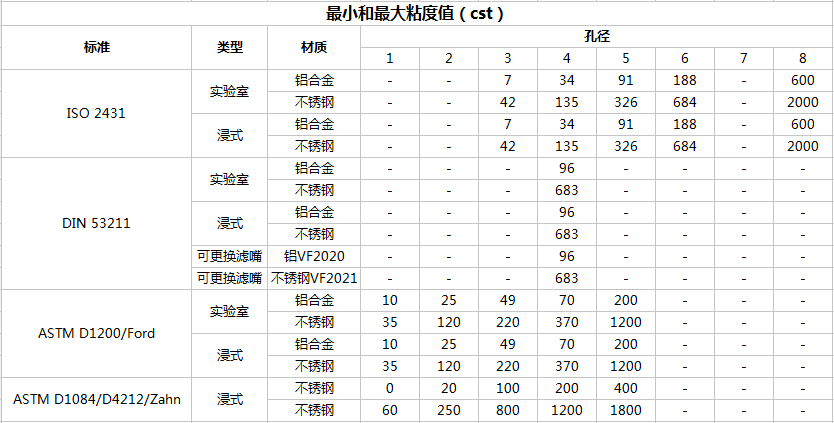

3) According to the specification table and the expected viscosity range of the liquid to be measured, select the appropriate pore sizeTQC immersion Viscosity Cup.

4) WillThe TQC immersion Viscosity Cup slowly dips into the paint viscosity until the top edge of the cup is able to submerge.

5) Put a thermometer into the Viscosity Cup and measure the temperature of the test sample.

6) Remove the thermometer.

7) Hook the handle ring with your fingers to keep the cup vertical. Maintain a steady state and quickly lift the Viscosity Cup from the sample when TQCThe immersion Viscosity Cup leaves the surface of the test paint to start the timer. During the liquid flow process, the Viscosity Cup should be kept above the surface of the sample, no more than 15 cm.

8) Stop the timer when the liquid flow beam is interrupted for the first time.

Maintenance method:

1. It is especially important to clean the outflow hole to remove residue and avoid scratching its inner surface.

2. Although the Viscosity Cup is designed to be strong, it is a precision instrument and should not be dropped or impacted.

3. It needs to be cleaned after use.

4. Please use soft cloth to clean the Viscosity Cup, and do not use such as wire brush or sandpaper. This is because this can be caused by corrosive cleaning agentsLong-lasting damage.

5. Do not directly tap the spout when disassembling the spout. Use the pin rod supplied with the Viscosity Cup against the spout before tapping with a heavy object (e.g., a paperweight).

6. Before installing the cup spout, please make sure that the cup spout and Viscosity Cup are clean.

7. When not in use, please useTQC immersion Viscosity CupPut it back in the box.

8. We recommend calibration once a year.

9. RightTQC immersion Viscosity CupThe maintenance can ensure the accuracy of the experiment

Product detail drawing

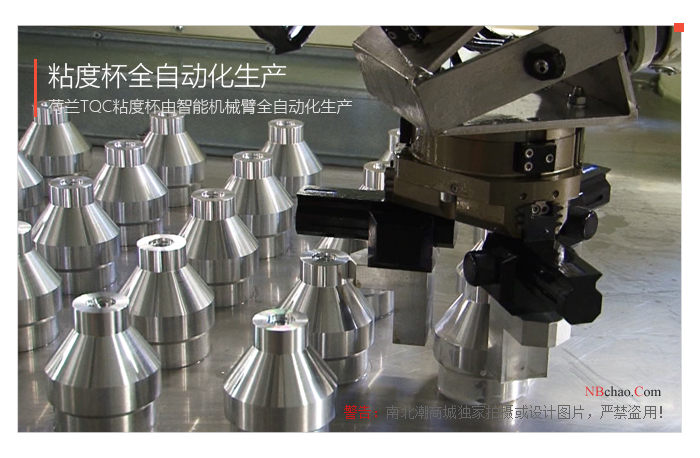

TQC Model Selection

Take you to the Dutch TQC

VF2073+Certificate

VF2073+Certificate