LEEB140 Leeb Hardness Tester built-in printer, standard D-type Impact device, optional Miscellaneous Impact device

SE-

Shore Hardness Gauge KAIRDA NDT280S Durable Shore hardness testing meter for rolls

Shore Hardness Gauge KAIRDA NDT280S Durable Shore hardness testing meter for rolls -

Handheld Leeb Hardness Tester KAIRDA NDT280 Metal shell Durable Hardness Gauge

Handheld Leeb Hardness Tester KAIRDA NDT280 Metal shell Durable Hardness Gauge -

Portable Leeb Hardness Tester KAIRDA NDT230 Plastic Housing Richter Hardness Test Meter

Portable Leeb Hardness Tester KAIRDA NDT230 Plastic Housing Richter Hardness Test Meter -

Metal Leeb Hardness Tester KAIRDA NDT290 + Hardness measurement of various metal materials

Metal Leeb Hardness Tester KAIRDA NDT290 + Hardness measurement of various metal materials -

Leeb Hardness Tester KAIRDA NDT290 Portable Richter Hardness Tester with printer

Leeb Hardness Tester KAIRDA NDT290 Portable Richter Hardness Tester with printer

Leeb leeb140 Leeb Hardness TesterSPEC

Leeb leeb140 Leeb Hardness TesterDetails

Leeb leeb140 Leeb Hardness TesterPacking list

- SKU

- NB001261

- Error of indication

- ±6HLD (HLD=760)

- Indication repeability

- 6HLD (HLD=760)

- Measurement direction

- 360°

- Hardness system

- HL/HB/HRC/HRB/HV/HS

- Optional impact device

- D、G、C、DL、DC、D+15

- PC communication

- Yes.

- Print roll diameter

- 26.7±0.5mm

- Printing paper width

- 56.5±0.5mm

- Power

- 4.7V-6V

- Charging time

- 6 hours

- Power

- 9V/600mA

- Dimensions

- 210*80*35mm

- Weight

- About 0.4Kg

- Optional accessories

- Various special-shaped support rings, standard Hardness blocks, communication software, 8 kinds of impact devices

Introduction

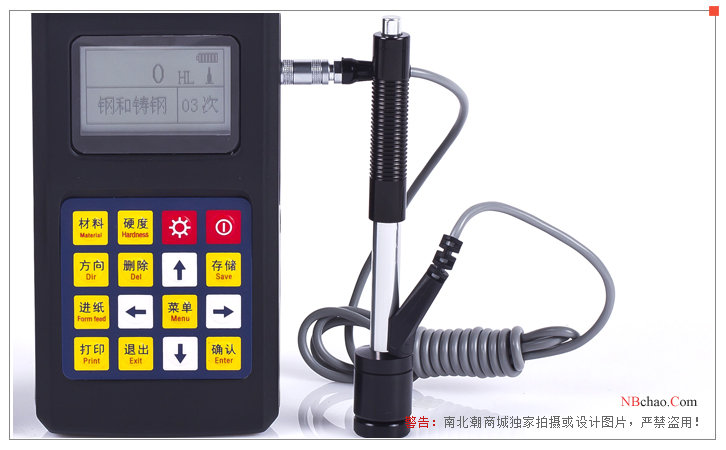

Libo leeb140 Leeb Hardness Tester is a multifunctional Leeb hardness measuring instrument with a built-in high-speed thermal printer. Tolerance can be set. It is equipped with a D-type impact device as standard. Other impact devices can be purchased according to actual needs. It is not necessary to replace the impact device. Calibration, with automatic identification function.

Leeb140 Leeb Hardness Tester adopts a full Chinese display screen, menu-style operation, simple and convenient, and can directly display various hardness values such as Leeb, Brinell, Rockwell, Vickers, and Shore. Small size, easy to carry.

Applications

1) Mold cavity.

2) Heavy workpieces.

3) Installed mechanical or permanent assembly parts.

4) Failure analysis of pressure vessels, turbogenerators and their equipment.

5) Measure workpieces with very narrow space.

6) Bearings and other parts.

7) Rapid inspection of multiple measuring parts in a large range of large workpieces.

8) Material classification of metal material warehouse.

Features

1. Leeb140 Leeb Hardness Tester is equipped with D-type impact device as standard.

2. Designed according to the principle of Leeb hardness measurement, it can perform three calibrations of Leeb, Rockwell, and Brinell, and the Rockwell measurement interface will be displayed when the machine is turned on.

3. The hardness and tensile strength can be converted to each other.

4. One leeb140 Leeb Hardness Tester host can be equipped with 7 different impact devices for use, no calibration is required for replacement, and automatic identification is required.

5. Use standard Rockwell hardness test blocks to save costs.

6. It can display the measured value, impact direction, test times, test material, average value, date, hardness system and other information.

7. The built-in thermal printer supports on-site instant printing to ensure the fairness of the measurement results and the long-term storage and traceability of the data.

8. You can input the test date and code.

9. It has the function of automatic shutdown and indication calibration.

10. The Leeb Hardness Tester has charging indication and low Voltage alarm function.

Pictures

Note: Leeb140 Leeb Hardness Tester has gray and black shells, users can choose one of them.

main application

1. When testing gear hardness, if the gear is too small, you need to choose DL impact device.

2. When testing castings, if it is difficult to express the smoothness, you need to choose the G-type impact device.

3. For the hardness testing of products in the process of mass production, generally a standard set can meet the testing requirements.

4. For hardness testing of annealing, tempering, quenching and other heat treatments, if there is a hardened layer, you need to pay attention to the thickness of the hardened layer. If the hardened layer is too thin, you need to choose a C-type impact device.

5. When testing the hardness of the bearing, it is necessary to pay attention to the bearing diameter. If the diameter is too small, it is necessary to select a special-shaped support ring.

Other types of impact devices

| serial number | Impact device type | Standard Leeb hardness block hardness value | Indication error | Indication repeatability |

| 1 | D. | 760±30 HL D 530±40HLD | ±6 HLD ±10 HLD | 6 HLD 10 HLD |

| 2 | DC | 760±30 HLDC 530±40 HLDC | ±6 HLDC ±10 HLDC | 6 HLD 10 HLD |

| 3 | DL | 878±30 HLDL 736±40 HLDL | ±12 HLDL | 12 HLDL |

| 4 | D+15 | 766±30HLD+15 544±40HLD+15 | ±12HLD+15 | 12HLD+15 |

| 5 | G | 590±40HLG 500±40HLG | ±12 HLG | 12 HLG |

| 6 | E. | 725±30HLE 508±40 HLE | ±12 HLE | 12 HLE |

| 7 | C | 822±30 HLC 590±40HLC | ±12 HLC | 12 HLC |

- 1DL/T 1845-2018《Test method for Leeb hardness of high-alloy steels in power equipment》

- 2GB/T 13313-2008《Methods of shore and leeb hardness testing for rolls》

- 3GB/T 17394.1-2014《Metallic materials―Leeb hardness test―Part 1: Test method》

- 4GB/T 17394.4-2014《Metallic materials―Leeb hardness test―Part 4:Tables of hardness values conversation》

- 5GB/T 17394.3-2022《Metallic materials—Leeb hardness test—Part 3: Calibration of reference test blocks》

- 6GB/T 17394.2-2022《Metallic materials—Leeb hardness test—Part 2: Verification and calibration of hardness testers》

- 7GB/T 17394-1998《Metallic materials--Leeb hardness test》

- 8GB/T 17394.3-2012《Metallic materials - Leeb hardness test - Part 3: Calibration of reference blocks》

- 9GB/T 17394.2-2012《Metallic materials - Leeb hardness test - Part 2: Verification and calibration of hardness testers》

- 10JB/T 9378-2001《Leeb hardness testers》

leeb140

leeb140