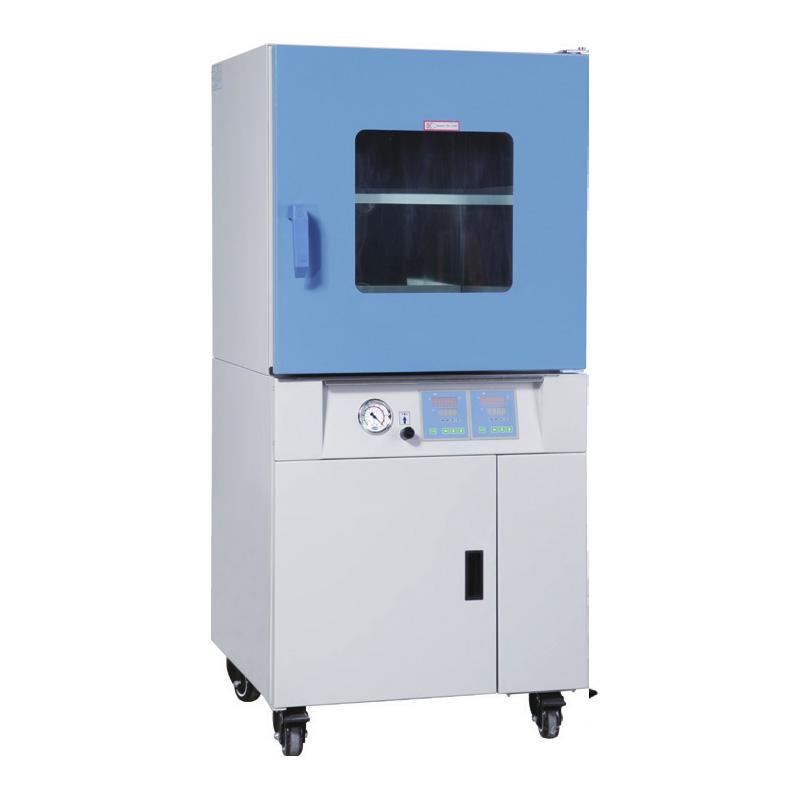

YIHENG BPZ-6123LC Vacuum Oven

SEYiHeng BPZ-6123LC Vacuum OvenSPEC

YiHeng BPZ-6123LC Vacuum OvenDetails

YiHeng BPZ-6123LC Vacuum OvenPacking list

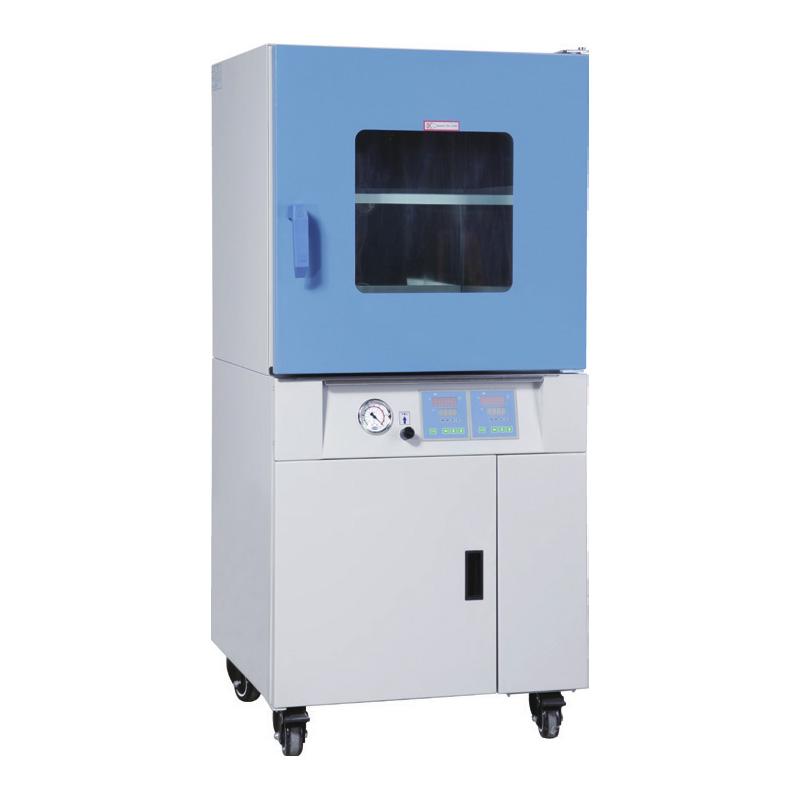

- SKU

- NB012847

- Temperature range

- RT+10~200℃

- Temperature Fluctuation

- ±1℃

- Temperature Resolution

- 0.1℃

- Interior size

- 500*500*500mm

- Chamber material

- Stainless steel 304 (1Cr 18Ni9Ti)

- Shelf (std.)

- 3pcs

- Vacuum meter

- digital display

- Vacuum Sensors

- Adopt resistance silicon tube pressure sensor

- vacuum

- 10~105Pa

- Power supply Voltage

- AC 220V 50Hz

- Input Power

- 2050W

- Dimensions

- 660*640*1400mm

- Net Weight

- 178kg

- Gross Weight

- 218Kg

- Packing size

- 770*800*1590mm

The vacuum Drying Oven series produced by Yiheng Instrument has the characteristics of short heating time, accurate control, safety and reliability, and can smoothly dry heat-sensitive substances and easily oxidized substances. Yiheng Instrument is a manufacturer that uses digital pressure sensors to automatically control the vacuum degree and Vacuum Pump through a microcomputer.

Features

● Cuboid studio, so that the effective volume utilization rate is large, microcomputer temperature controller, accurate and reliable temperature control.

● Tempered, bulletproof double-glazed door to observe the objects in the studio, at a glance, can be filled with inert gas.

● The door closure is adjustable and the silicone rubber door sealing ring is integrated to ensure a high vacuum degree in the box.

● The studio is made of stainless steel sheet material to ensure that the product is durable and easy to clean.

● Storage, heating, testing and drying can be carried out in an environment without oxygen or filled with inert gas, which will not cause oxidation.

● Shorten the drying time, compared with the traditional vacuum Drying Oven, the drying time is reduced by more than 50%.

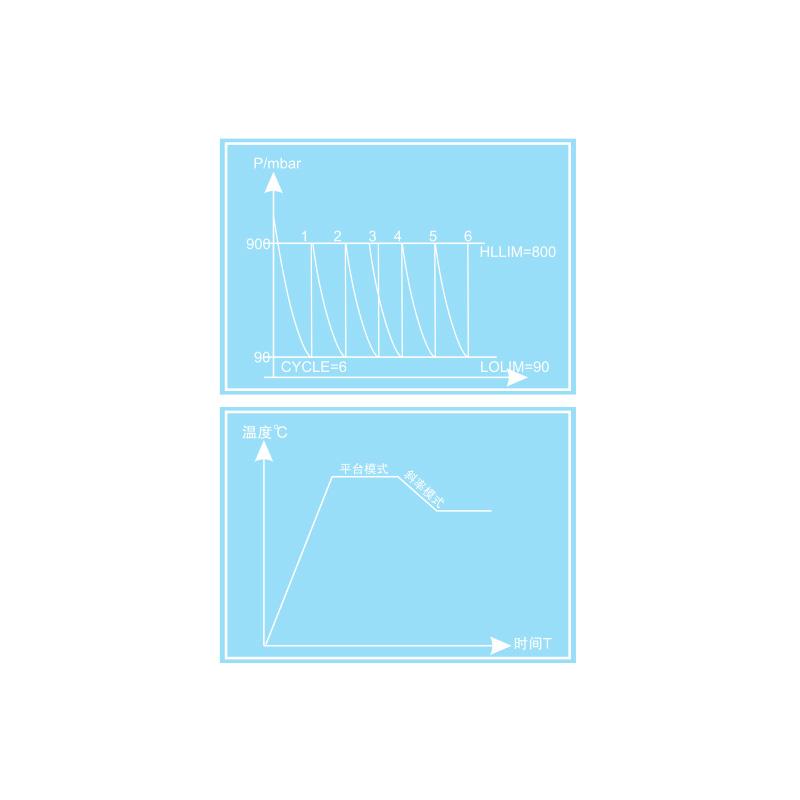

Drying process control

Vacuum drying process control can provide programmed vacuum cycles, which can further reduce drying times by simply setting the maximum and minimum vacuum values according to your requirements. For example, the vacuum cycle is controlled by the program, the minimum vacuum degree is set to 50Pa, the maximum vacuum degree is 900Pa, the number of cycles is 6 times, and the drying process is shown in the figure. With each cycle, the humidity decreases and the drying speed is significantly accelerated, up to a maximum of 99 cycles.

Cycle program control function

Humanized operation interface and programming program, saving customer time, to ensure a reliable heating or drying process, can be directly programmed in the operation interface, can be preset 7 groups of 63 steps programmable, each group of setting time 1-99 hours 59 minutes, can preset the start and shutdown time.

Vacuum control

Vacuum Drying Oven uses digital technology to control the vacuum degree, "manual control" has long become a thing of the past, do you still think that in the 21st century, the manual lever operated valve can accurately control the vacuum degree? Through the panel, the vacuum degree can be easily controlled in the range of 10~10 5 Pa (the minimum vacuum degree is 133Pa) between any two points or areas, and the control accuracy is ±1%. The vacuum gauge uses a resistive silicon tube pressure sensor, so as to ensure a stable pressure value, which is not affected by the air flow, and transmits the stable pressure value to the LED display of the vacuum gauge.

Advantages of temperature control

It has 7 groups of 63-step temperature programmable functions: it has the traditional program control mode, and can also set the temperature and constant temperature time, which means "temperature ~ the temperature constant temperature time", and BPZ-LC also contains slope mode program control, which should be defined in the format of "temperature-time-temperature": the time required to rise or fall from one temperature to another, so as to accurately realize the rate control of the rising or cooling process. This allows you to control every process throughout the temperature experiment, whether it is heating up, constant temperature or cooling down.

- 1JB/T 11365-2013《Vacuum dryer》

- 2SJ 21318-2018《General specification for vacuum high-temperature ovens》

- 3GB/T 8077-2023《Methods for testing uniformity of concrete admixtures》

- 4GB/T 8576-2010《Determination of free water for compound fertilizers - Vacuum oven method》

- 5HG/T 5164-2017《Textile dyeing and finishing auxiliaries - Water-borne polyurethane emulsions for textile coating》

- 6GB/T 5211.3-1985《Determination of volatile matter of pigments at 105℃》

- 7JB/T 9505-1999《Vacuum oven》

- 8JB/T 5520-1991《Technical conditions for drying oven》

BPZ-6123LC

BPZ-6123LC