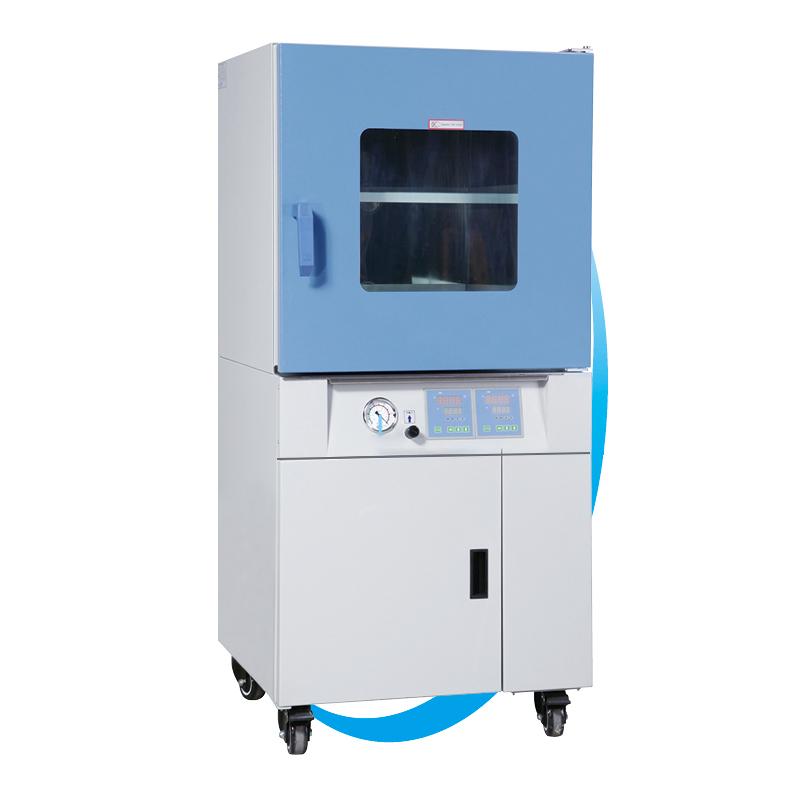

YIHENG BPZ-6933B Vacuum oven equipped with mechanical pointer vacuum meter

SEYiHeng BPZ-6933B Vacuum ovenSPEC

YiHeng BPZ-6933B Vacuum ovenDetails

YiHeng BPZ-6933B Vacuum ovenPacking list

- SKU

- NB012877

- Temperature range

- RT+10~200C

- Temperature Fluctuation

- ±1℃

- Temperature Resolution

- 0.1℃

- Inner chamber materials

- Stainless steel 304 (1Cr~ 18Ni9Ti)

- Interior size W * D * H

- 750x1160x1050

- Environmental temperature

- +5~40℃

- shelves (max)

- 4 pieces/5 pieces (independent temperature control)

- Vacuum meter

- mechanical pointer

- vacuum

- 133Pa

- Input Power

- 3800W/5600W

- Power supply Voltage

- AC380V 50HZ

- Dimensions W * D * H

- 1400x1395x2010

- Note

- Remarks: The performance parameters are tested under no-load conditions: Environmental temperature 20 ° C, Environmental humidity 50% RH 1. With "B" is a high-quality brand vacuum pump. 2. BPZ series Vacuum oven with vacuum pump and drying tank

This product is suitable for heat treatment in vacuum conditions such as defoaming, dehydrating, hardening and drying after washing treatment in the production process of electronic products, and is widely used in the vacuum drying treatment of lithium-ion batteries, LED optoelectronic components, crystal oscillators and other electronic product production processes.

Features:

● The working room is made of stainless steel plate, ensuring that the product is durable and easy to clean.

● Rectangular vacuum chamber, so that the effective volume utilization rate is large, and the space can be fully utilized.

● The elastic double-layer tempered glass door observes the objects in the workshop at a glance.

● The door closure is adjustable and the synthetic silicone rubber door is sealed to ensure a high vacuum degree in the box.

● Add over-temperature protection temperature control port to effectively prevent safety problems such as temperature runaway. (Optional)

● Low noise high-quality brand Vacuum Pump, stable and reliable vacuum control. (With "B" for high-quality brand Vacuum Pump)

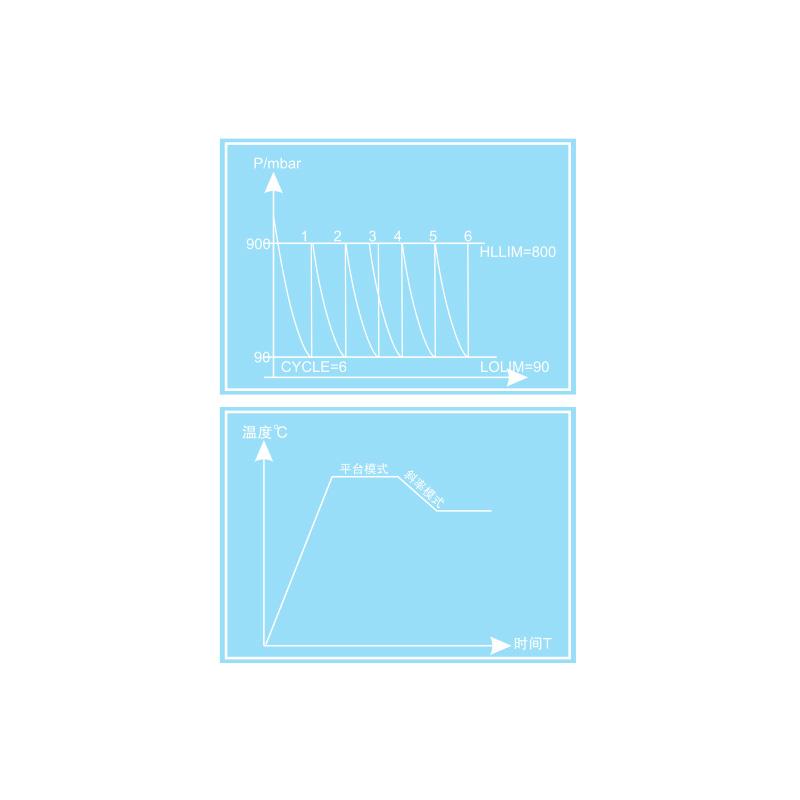

◆Program control (optional)

● Program control operation, heating, vacuum holding, and nitrogen holding time can be set according to process requirements to ensure consistency in baking each batch and minimize product baking variability.

Optional parts:(Increase the delivery time of optional parts by 7 days)

1. Inert gas inlet valve

2. Liquid water filter (priced according to specifications and models, suitable for high humidity drying)

3. Drying tank

4. Optional exhaust oil filtration device (it is recommended to replace it once every 6 months)

- 1JB/T 11365-2013《Vacuum dryer》

- 2SJ 21318-2018《General specification for vacuum high-temperature ovens》

- 3GB/T 8077-2023《Methods for testing uniformity of concrete admixtures》

- 4GB/T 8576-2010《Determination of free water for compound fertilizers - Vacuum oven method》

- 5HG/T 5164-2017《Textile dyeing and finishing auxiliaries - Water-borne polyurethane emulsions for textile coating》

- 6GB/T 5211.3-1985《Determination of volatile matter of pigments at 105℃》

- 7JB/T 9505-1999《Vacuum oven》

- 8JB/T 5520-1991《Technical conditions for drying oven》

BPZ-6933B

BPZ-6933B