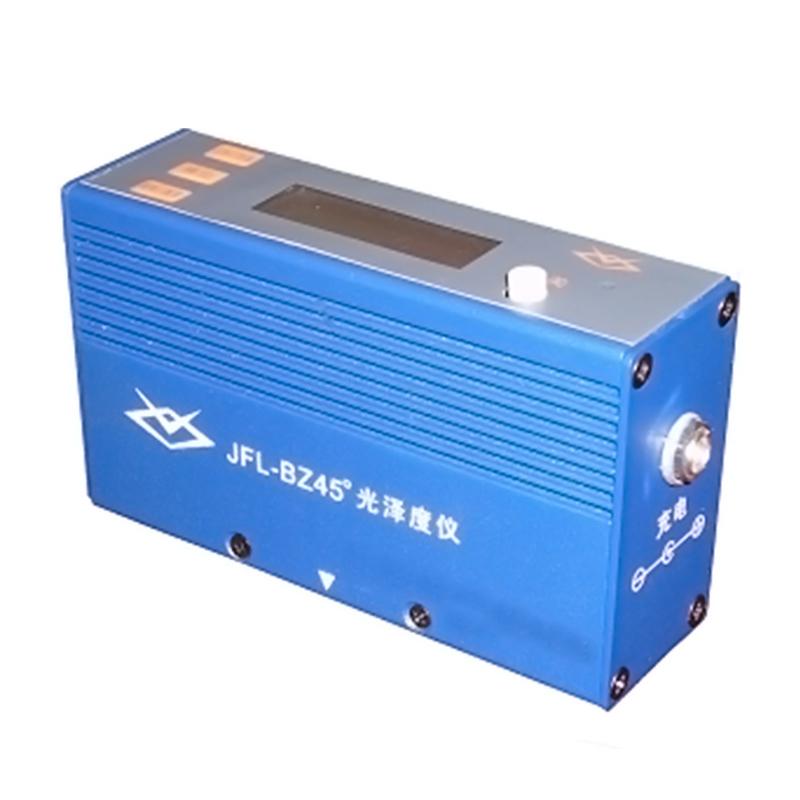

Mirror Glossmeter JFL-BZ45 (Ceramic, Plastic film smart) JFL

SEJFL JFL-BZ45 (Ceramic, Plastic film smart) GlossMeterSPEC

JFL JFL-BZ45 (Ceramic, Plastic film smart) GlossMeterDetails

JFL JFL-BZ45 (Ceramic, Plastic film smart) GlossMeterPacking list

- SKU

- NB001301

- Geometry

- 45°

- Measurement range

- 0~300GU

- Measuring Areas

- 10*14mm

- Error of indication

- ±1.2GU

- Division Value

- 0.1GU

- Standards

- ASTM-C346、ASTM-D2457、GB8807、GB/T3295

- Operating language

- Chinese

- Dimensions

- 114*35*65mm

- Weight

- 300g

- Power

- NiMH rechargeable battery

- Stability

- ±0.4GU

- Measurement port size

- 14*20mm

- Working Voltage

- 4.8V

- Application

- Plastic film, Pottery and porcelain, Enamel, Lacquerware

- Measurement port shape

- ellipse

Introduction

Jinfulan JFL-BZ45 Specular Gloss Meter is an intelligent Specular Gloss Meter with a measurement projection angle of 45 degrees, which is specially used to measure the surface gloss of plastic films and ceramics. JFL-BZ45 Specular Gloss Meter adopts a long-life Ni-MH rechargeable battery, which is small in size and has high accuracy and stability in measuring gloss. As an intelligent gloss meter, it has a larger display range than ordinary gloss meters. Twice as high, the measurement range is 0.0~300.0Gs.

Steps

The measurement method of JFL-BZ45 specular gloss meter is relatively simple, as follows:

1. Press the switch, and the JFL-BZ45 mirror gloss meter is in the measurement mode.

2. Put the measurement window of the JFL-BZ45 specular gloss meter on the sample, and the value displayed at this time is the gloss value of the sample.

Note: When the measured value is greater than 300.0 gloss units, the word "OVER" will be displayed.

Calibration method

During the use of the JFL-BZ45 specular gloss meter, if the value displayed on the standard plate differs greatly from the nominal value of the standard plate, it is necessary to calibrate the gloss meter. The specific calibration method is as follows:

1. Put the measurement window of the JFL-BZ45 specular gloss meter on the black velvet board, press the "set number/zero" button, and the value will be displayed at this time

is 0.0.

2. Replace the black velvet board with a black glass standard board, put it under the measurement window of the JFL-BZ45 specular gloss meter, press the "calibration/measurement" button to enter the setting state, and then display "000.0" and the first "0" " flashes.

3. Press the "Shift" key to move the flickering digit to the right, and press the "Number/Zero" button to change the value of the "blinking" digit from 0-9-0. By pressing the "Shift" and "Number/Set" Zero" key to make the displayed value the same as the nominal value of the black glass standard plate, then press the "Calibration/Measurement" key to complete the setting.

4. JFL-BZ45 Specular Gloss Meter is placed on the white ceramic standard plate, the error between the displayed value and the nominal value of the white ceramic standard plate

The difference should not be greater than ±1.2 gloss units, otherwise problems such as contamination of the standard plate should be considered.

5. After calibration, the sample can be measured.

Pictures

- 1GB/T 11420-2024《Vitreous and porcelain enamels—Test method of specular glossiness》

- 2GB/T 11420-1989《Measurement of specular gloss of vitreous and porcelain enamels》

- 3GB/T 10003-2008《Biaxially oriented polypropylene(BOPP) film for general use》

- 4GB/T 4456-2008《Polyethylene blown film for packaging applications》

- 5GB/T 8941-2013《Paper and board—Measurement of specular gloss》

- 6GB/T 15614-2015《Test method for measuring the glossiness of ceramic pigment》

- 7JJG 696-2015《Specular Gloss Meters and Gloss Plates》

- 8ASTM D3928-2018《Standard Test Method for Evaluation of Gloss or Sheen Uniformity》

- 9ISO 2813-2014《Paints And Varnishes - Determination Of Gloss Value At 20 Degrees, 60 Degrees And 85 Degrees》

- 10GB/T 1766-2008《Paints and varnishes - Rating schemes of degradation of coats》

JFL-BZ45 (Ceramic, Plastic film smart)

JFL-BZ45 (Ceramic, Plastic film smart)