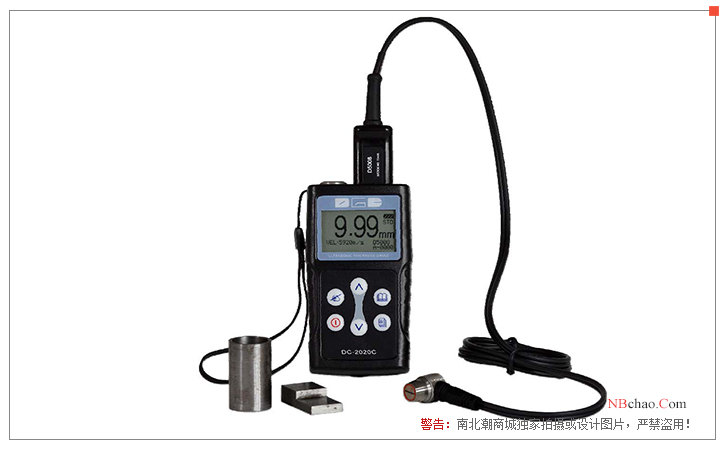

Ultrasonic Film thickness Measurement Instrument DC-2020C Deguang Electronics, Film thickness measurement of metal, plate, pipeline, etc

SE-

High-precision ultrasonic Thickness Gauge DC-6000 Deguang Electronics, suitable for high-precision measurement of ultra-thin parts$ 2439.00SE

High-precision ultrasonic Thickness Gauge DC-6000 Deguang Electronics, suitable for high-precision measurement of ultra-thin parts$ 2439.00SE -

LANDTEK TM-1240 Ultrasonic Thickness Gauge$ 322.00SE

LANDTEK TM-1240 Ultrasonic Thickness Gauge$ 322.00SE -

JINGHAI DC-2020 Thermostatic Bath Temperature range: -20 ℃~ 95 ℃$ 2049.00

JINGHAI DC-2020 Thermostatic Bath Temperature range: -20 ℃~ 95 ℃$ 2049.00 -

Ultrasonic Thickness Gauge DC-4000, automatic and manual measurement$ 2189.00SE

Ultrasonic Thickness Gauge DC-4000, automatic and manual measurement$ 2189.00SE -

Metal Ultrasonic Film thickness meter DC-3020C Deguang Electronic Glass, steel pipe and other Film thickness measurement$ 1562.00SE

Metal Ultrasonic Film thickness meter DC-3020C Deguang Electronic Glass, steel pipe and other Film thickness measurement$ 1562.00SE

DGC DC-2020C Thickness GaugeSPEC

DGC DC-2020C Thickness GaugeDetails

DGC DC-2020C Thickness GaugePacking list

- SKU

- NB001336

- Measuring range

- 0.8~300mm

- Probe frequency

- 5MHz

- Probe style

- Split probe (D5008)

- Probe contact temperature

- <60℃

- Measurement error

- Low precision: 0.65mm~ 99.9mm ± 0.1mm 100.0mm~ 400.0mm ≤ 0.3% High precision: 0.8mm~ 9.99mm ± 0.04mm 10.00mm~ 99.99mm ± (0.1% + 0.04) mm 100.0mm~ 400.0mm ≤ 0.3% Hmm Note: H is the measurement of Film thickness value

- Display resolution

- 0.1/0.01mm

- unit system

- mm/inch

- Measurement mode

- Average, Limit, MIN Minimum, Difference

- Storage Capacity

- 5000 sets

- Sound speed range

- 1000~9999m/s

- Display

- 128X64 LCD four-bit dot matrix liquid crystal display (with LED backlight)

- Operating language

- Chinese

- Data Interface

- USB

- Application software

- Yes.

- Operating Temperature

- -20~50℃

- Storage temperature

- -20~50℃

- Power

- 2 * 7 AAA battery

- Operating Time

- 48h

- Host size

- 116*64*27mm

- Weight

- 220G (including battery)

- Measurement speed

- Ordinary measurement 2 times/second; high-speed measurement 10 times/second

- Shutdown method

- 1 minute, 3 minutes, 5 minutes automatic shutdown optional

Introduction

In appearance, Deguang Electronics DC-2020C Ultrasonic Thickness Measuring Instrument is a black plastic shell with a liquid crystal display, a USB interface and a probe socket, and the keyboard has six keys (including: power switch key \ return key or exit key (in the menu) ); Menu key\Enter key (in the menu); Backlight key\Up key (in the menu); Zero calibration key\Down key (in the menu); Storage key; Read key ).

Functionally, DC-2020C Ultrasonic Thickness Measuring Instrument can not only directly measure the thickness of the material under test, but also reversely measure the thickness value of the material under test through the speed of sound. DC-2020C ultrasonic Thickness Gauge is a non-penetrating ultrasonic Thickness Gauge.

Features

1. DC-2020C Ultrasonic Thickness Measuring Instrument uses a liquid crystal display to check the thickness measurement data in real time.

2. You can choose one of 1 minute, 3 minutes, and 5 minutes to set the automatic shutdown.

3. Four measurement methods: average measurement, limit measurement, minimum measurement, differential measurement.

4. The function of sound velocity measurement is powerful, and functions such as material selection, sound velocity input, sound velocity measurement, and sound velocity storage can be selected.

5. DC-2020C ultrasonic thickness measuring instrument is an intelligent thickness measuring instrument with a storage function of 5000 sets of measurement data.

6. High indication accuracy: 0.01mm.

Probe Calibration Method

In actual measurement, the DC-2020C Ultrasonic Thickness Meter after automatic calibration will produce a small measurement deviation with the change of time and environment. Using the calibration function of the DC-2020C Ultrasonic Thickness Meter can eliminate this deviation at any time. The steps are as follows:

①Wipe the surface of the probe clean without leaving any couplant

②Press the down key, select "Probe Calibration" and enter the measurement state after automatic zero calibration.

Measurement Notes

①When measuring, only when the measurement indicator appears and is stable, it is a good measurement.

②If there is a large amount of couplant on the surface of the measured body, when the probe leaves the surface of the measured body, the couplant will cause mismeasurement. Therefore, when the measurement is over, the probe should be moved away from the surface of the measured body quickly.

③ If the probe is worn, the measurement will show unstable value, and the probe should be replaced.

④ When using ordinary probes, it should be remembered that the temperature of the workpiece to be measured should not be higher than 60°C, otherwise the probe is easily damaged.

Pictures

- 1Analysis of application status of pipeline coating

中国石油管道科技研究中心 沈光霁 陈洪源 薛致远 赵 君 - 《腐蚀科学与防护技术》

- 2Dry goods | Coating Thickness Gauge working principle and FAQ summary

杨琳 - 《浅谈涂层测厚仪工作原理与常见故障》

- 3Measuring methods of coating Thickness Gauge

- 4How to choose a Thickness Gauge?

- 5How to choose a suitable painting Thickness Gauge?

- 6Correct use of Film Thickness Gauge

张瑞;张月富

- 7Introduction of nondestructive thickness testing principle and instrument

- 1JJF 1224-2009《Calibration Specification for Reinforced Concrete Covermeter and Floorslab Thickness Tester》

- 2JJF 1126-2004《Calibration Specification for Ultrasonic Thickness Instruments》

- 3JB/T 11604-2013《Non-destructive testing instruments.Ultrasonic thickness gauge》

- 4ASTM E797-2021《Standard Practice for Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact Method》

- 5GB/T 11344-2008《Non-destructive testing - Practice for measuring thickness by ultrasonic pulse-echo contact method》

- 6JJF 1126-2004《Ultrasonic Thickness Gauge calibrating specification》

- 7ZB N 77001-1989《General Technical Conditions for Ultrasonic Thickness Gauge》