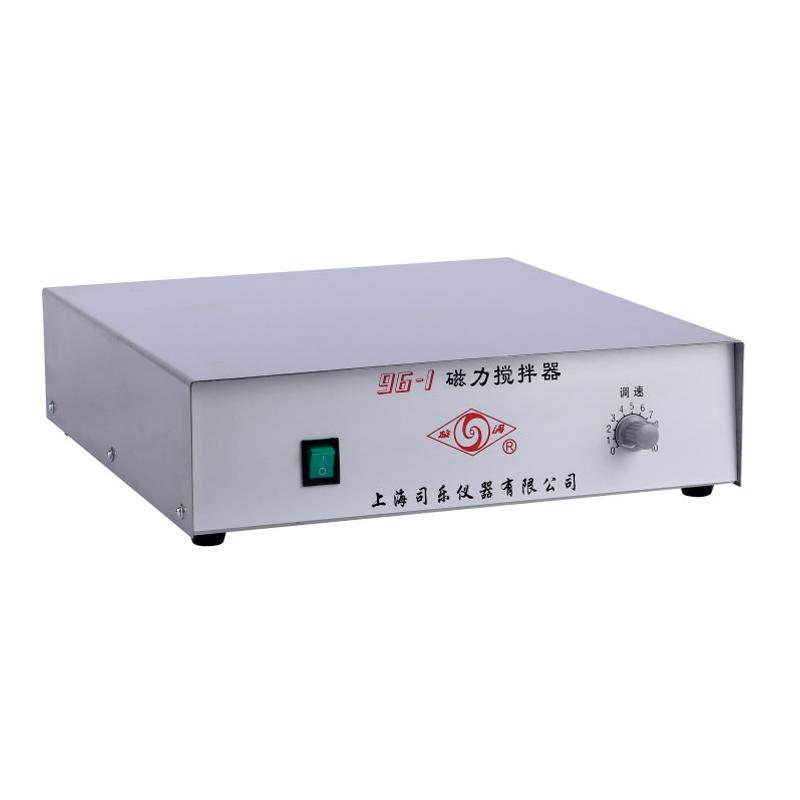

SILE 96-1 magneticstirrer

SESILE INTRUMENT 96-1 MagneticstirrerSPEC

SILE INTRUMENT 96-1 MagneticstirrerDetails

SILE INTRUMENT 96-1 MagneticstirrerPacking list

- SKU

- NB013427

- Max. Capacity of stirring

- 50L

- Stirring speed

- 50~1500rpm

- Stirring power

- 100W

- Dimensions

- 410*400*200mm

- Total Weight

- 12.5kg

- Power

- Ac220V±15%

- Operating Mode

- continuous

overview

1. It adopts a stainless steel shell, a new type of switching power supply, and a self-developed high-power brushless DC three-phase motor as the driving motor. The motor has the characteristics of no spark, high efficiency, large torque, low temperature rise, and can stir and mix liquids with low to high viscosity. It is suitable for lamps and lamps manufacturers who work continuously in three shifts for a long time. The application of this machine on the magnetic stirrer is unique in the domestic (CN) production of magnetic stirrer industry.

2. Using strong magnetic force magnetic steel, the stirring force is extremely strong. It can stir more media at one time, saving manpower and material resources, and improving production efficiency.

Instructions

1. Test run Before use, professionally conduct a test run with no load; connect the power, turn on the power switch, adjust the speed control knob clockwise, and listen carefully to hear the sound of the motor turning from slow to fast. If there are other abnormal noises, the cause needs to be found out. Can only be used after exclusion.

2. Stirring operation: put the machine flat, put the container containing the solution in the center of the workbench (that is, the electric furnace), put a suitable stirring bar in the container, (it needs to be sucked into the center, use a cylindrical stirring bar for a flat-bottomed container, and a spherical container Use a spinning agitator) to start the machine. The container should not be made of iron or materials related to magnetism, the thickness of the bottom should not be greater than 10mm, and it should be smooth. The stirring speed should be gradually accelerated from slow to fast. If the acceleration is too fast, the stirring bar will easily escape. If the stirring bar is not in the center of the container, you can turn on the stirrer first, let it idle for a while and then turn it off, the stirring bar will automatically suck into the center.

3. Note: The power supply needs to be reliably grounded; the solution in the container should not be overfilled to avoid overflow during stirring; the heating part of the machine cannot be used alone; the weight of the container cannot be concentrated on the center of the machine.

4. When the stirrer has been used for a long time and wears too much, and when a large flat surface appears, replace it with a new one, otherwise the machine will be damaged and cannot work normally.

- 1Magneticstirrer operating procedures, precautions and instructions for use

- 2Difference between Overhead Stirrer and magneticstirrer

- 3Shanghai Sile 96-1 magneticstirrer manual

- 4Sile magneticstirrer selection table [selection]

- 1GB/T 5541-2017《Disperse dyes—Determination of stability of dispersion at high temperature—Filter test of double filter papers》

- 2GB/T 6368-2008《Surface active agents - Determination of pH of aqueous solution - Potentiometric method》

- 3GB/T 33546-2017《General technica standard of electromagnetic stirrer》

96-1

96-1