Paint film cross-cut instrument, specially used for paint film cross-cut test instrument with solid substrate paint film below 60μm

TQC sheen SPEC

TQC sheen Details

TQC sheen Packing list

- SKU

- NB001352

- Number of teeth

- 6 teeth

- Tooth spacing

- 1mm

- Application standard

- ISO/DIN 2409

There are many brands and models of scratching instruments used in the scratching experiment of the paint film, but there are not many characteristics, this issue mainly recommends three paint film scratching instruments produced in the TQC, a major European manufacturer, for the test conditions of the paint film layer below 60 microns and the solid substrate.

Conditions apply: Less than 60um film thickness cut substrate is firm

The first: a paint film scratcher equipped with a blade holder for more repeatable tests

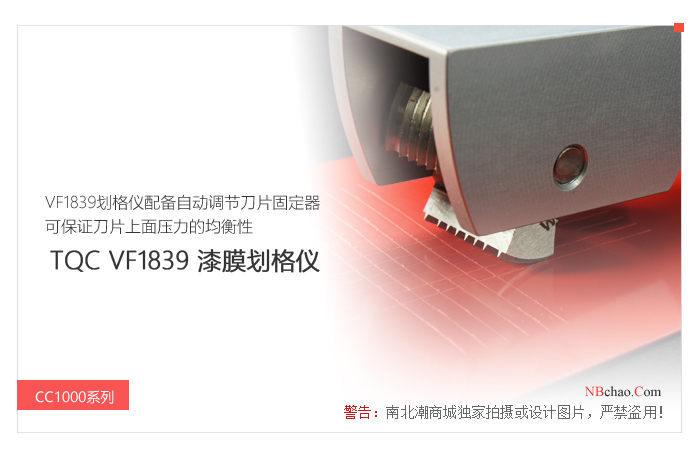

CC1000 series, model VF1839 paint film scratcher

The scratcher is ISO/DIN2409 compliant and has a head with 6 teeth and a 1 mm tooth spacing. VF1839Paint film scratching instrumentThe circular incision has 8 incisions. What is more distinctive is that the VF1839 grid retainer is equipped with a blade holder, which can be automatically adjusted to ensure that the force on the blade is uniform, making manual testing more repeatable.

The second model: equipped with a rotating handle to realize the free change of the cutter

CC2000 series, model SP1690Paint film scratching instrumentIn addition to the self-adjusting blade holder, a swivel handle is included for easy knife changes without the need for additional tools. SP1690 is also ISO/DIN2409 compliant and is recommended for scratching films up to 60 microns with strong substrates

The third model: a paint film scratcher that can automatically adjust the cutting depth

CC3000 series, model SP1680 scribing instrument can adjust the accuracy according to specific test needs to achieve precise cutting depth, so as to test adhesion more accurately. Compared with other brands of scribing instruments, SP1680Paint film scratching instrumentUsed for different coating film thicknesses and substrate sizes according to the standard, and it is very convenient to apply a variety of adhesion tests by simply adjusting.

The above three paragraphsPaint film scratchingThe instrument is suitable for the paint film scratching test with a solid substrate and a dry film thickness of less than 60μm, this page only presents the characteristics of the three, and the specific model and description can refer to the series manual.

- 1JJF 2163-2024《Calibration Specification for Paint Film Scribers》

- 2SJ 20910A-2018《General specification for powder spraying coating》

- 3GB 10810.4-2012《Uncut finished spectacle lenses - Part 4: Specifications and test methods for anti-reflective coatings》

- 4HG/T 5299-2018《Optical polyethylene terephthalate(PET) transparent hardening film for indium tin oxide(ITO)》

- 5QJ 990.14-1986《Coating inspection method coating adhesion inspection method》

- 6GB/T 9286-1998《Paints and varnishes cross-cut test》