Cross Hatch Cutter Solid and soft substrates Universal 6-tooth paint film cross-cutting instrument

TQC sheen SPEC

TQC sheen Details

TQC sheen Packing list

- SKU

- NB001353

- Number of teeth

- 6 teeth

- Tooth spacing

- 2mm

- Application standard

- ISO/DIN 2409

This paint film scratcher is one of the three applications of TQC imported from the NetherlandssameThe paint film scratcher, howeverEach has different characteristics, and it is designed for different scratching experimental occasions and user habits to design different functions of paint film scratchers.

Applicable objects: soft substrates with a film thickness of less than 60 microns and strong substrates with a film thickness of 61~120 microns, bifunctional type.

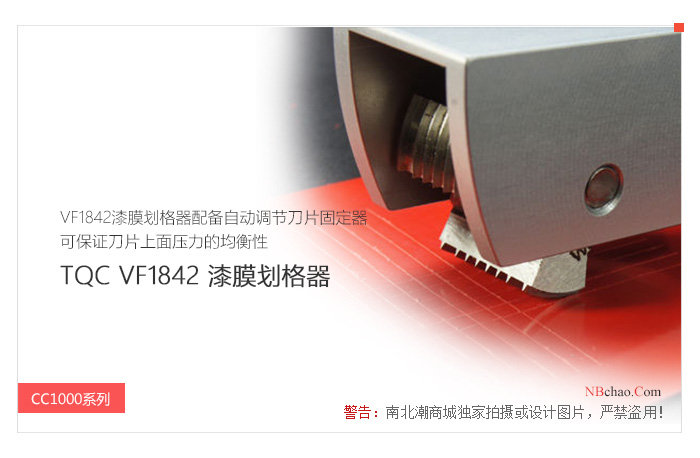

The first: a paint film scratcher with adjustable blade holder

Model: CC1000 series, VF1842

The paint filmThe griddle is characterized by a self-adjusting blade holder to ensure a better performance of the blade under uniform force, and a rounded head with 8 cuts. VF1842Paint filmThe number of teeth of the cutter head of the scratcher is six, and the spacing between the cutter teeth is 2mm.

The second: a paint film scratcher with automatic adjustment of the blade holder and a rotating handle

Model: CC2000 series SP1691

The special feature of this paint film scratcher is that it not only has a self-adjusting blade holder, but also comes with a rotating handle that automatically changes and adjusts the cutter without the need for additional tools, resulting in better measurement uniformity.The SP1691 has 6 teeth, which is in accordance with the standard ISO/DIN2409.

The third one: a paint film scratcher that can freely adjust the cutting depth

Model: CC3000 series, SP1681

The distinctive feature of this paint film scratcher is that the blade holder maintains a fixed distance between the paint film surface and the two auxiliary wheels, which can be adjusted freely and accuratelyPaint film scratcherThe depth of the cut to ensure that the results of the scribing experiment are well repeated.SP1681The paint film scriber complies with ISO/DIN2409 standards and has 6 teeth.

The above is a detailed introduction to the three types of paint film scratchers, and more specific information needs to read the product manual.The application objects of the three types of paint film scratchers are the same, each with its own characteristics, and users can choose freely according to the actual situation.

- 1JJF 2163-2024《Calibration Specification for Paint Film Scribers》

- 2SJ 20910A-2018《General specification for powder spraying coating》

- 3HG/T 5299-2018《Optical polyethylene terephthalate(PET) transparent hardening film for indium tin oxide(ITO)》

- 4QJ 990.14-1986《Coating inspection method coating adhesion inspection method》

- 5GB/T 9286-1998《Paints and varnishes cross-cut test》