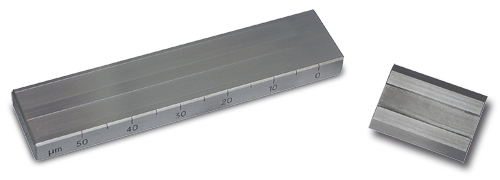

Erichsen 232 fineness grindometer 0~15μm Coating Fineness gauge

SE

Erichsen Erichsen 232/15μm Fineness of Grind GaugeSPEC

Erichsen Erichsen 232/15μm Fineness of Grind GaugeDetails

Erichsen Erichsen 232/15μm Fineness of Grind GaugePacking list

- SKU

- NB013679

- Scraper type

- double-channel

- Number of grooves

- 2

- range

- 0~15μm

- Scale unit

- μm、Hgeman

- Graduation

- 1.5μm

- Scraper size

- 125mm

- scraper material

- stainless steel

- Drawdown blade material

- stainless steel

Principle

The Fineness Meter Erichsen 232 is used to measure the fineness of the paint, which scrapes the test paint into a beam shape and visually detects that the particle size of the paint is greater than the height of the beam groove

The depth of the groove is read at the position of the dividing line between smooth and uneven on the surface of the sample, which is the fineness value of the coating.

devise

The Erichsen 232 fineness gauge is made from a single piece of hardened steel that has been specially treated to ensure dimensional stability, with two precisely machined girder grooves cut into the hardened steel. The height of the tank in μm on one side of the tank, the corresponding Hegman scale (HS) on the other side, other scales can also be customized on request, and the conversion relationship between the commonly used fineness units is shown in the following chart: The standard Erichsen 232 fineness measurement range is 15/25/50/l00μm, and a straight-edged scraper for film scraping is included in the scope of delivery.

Measurement process

Pour enough test material into the deeper end of the girder groove, be careful not to produce air bubbles, hold the scraper, perpendicular to the fineness plate and the groove, and smoothly scrape the material towards the narrow end of the groove, the stroke takes 1-2 seconds to complete.

The evaluation should be carried out within 3 seconds of scraping, with a view perpendicular to the groove and an angle of view of 20-30 degrees, to find out where the particles accumulate or scratch to appear, and the corresponding groove depth is the fineness of the test material.

Maintenance:

Fineness Meter #232 should be cleaned with solvent immediately after use, and do not use anything sharp and hard to remove any remaining paint. The straight edge used by the scraper will be subjected to continuous wear, so the minimum force should be applied during operation, and after a certain period of time, the scraper should be placed on a horizontal plane (such as along the longitudinal direction of the fineness plate), and then checked according to the principle of light transmission.

- 1Frequently Asked Questions about Fineness Plates in 2022

- 2How to use Fineness of Ground Gauge to measure colorants?

- 3Fineness gauge selection guide notes

- 4Basic Principle and Application Analysis of Coating Fineness Scraper

- 5Inks Fineness gauge principle results and usage introduction

- 6Coating fineness test method and influencing factors

- 1SJ/T 10454-2020《Dielelectric paste for multilayer lay out of thick film hybrid integrated circuits》

- 2HG/T 5173-2017《Waterborne primer for application on rusty substrates》

- 3GB/T 42541-2023《Coated steel pipes for gas piping》

- 4GB/T 21894-2008《A kind of photosensitive emulsion for plate making on fabric rotary screen printing》

- 5HG/T 5776-2020《Water-based coatings for surface of rubber sealing products》

- 6HG/T 5175-2017《Water-based decorative coating for glass and ceramic products》

- 7ASTM D3794-2022《Standard Guide for Testing Coil Coatings》

- 8QB/T 5477-2020《Water-based printing ink for decorating paper》

- 9ASTM D1210-05-2022《Standard Test Method for Fineness of Dispersion of Pigment-Vehicle Systems by Hegman-Type Gage》

- 10JB/T 9385-2017《Scraper fineness gauges》

Erichsen 232/15μm

Erichsen 232/15μm