CHINA 2ac-12/01 Spinning Coater Spin Coater

SEHuiNuo 2ac-12/01 Spin CoaterSPEC

HuiNuo 2ac-12/01 Spin CoaterDetails

HuiNuo 2ac-12/01 Spin CoaterPacking list

- SKU

- NB013759

- Power Supply

- AC200-230V, single phase, 200W

- loading diameter

- Negotiate;

- program group

- Segments 1-5 (edit pages), 12 groups

- homogenizing time

- 3000S, resolution 0.1S

- speed correction

- Rotation speed can be automatically corrected by selecting Kx practice run through A/K, and then go back to Kx to use

- Acceleration

- No such function or 100-3000RPM/S range, resolution 1RPM/S

- Dimension

- 250Mm (W) x420mm (D) x230mm (H) Height without pot

- Weight

- Spin coater 14KG, optional vacuum pump 5KG

- Vacuum input requirements

- 0.06-0 MPa, Vacuum Flow rate 40 L/Min or more

- Vacuum interface

- Comes with 6mm tube 1 meter

Overview

A Spin Coater is a device used for coating thin films, adhesive liquids, or other liquid materials onto the surface of substrates. Its operating principle is based on centrifugal force. Spin Coaters are critically important in fields such as semiconductor manufacturing, optical coatings, and material science, particularly in processes like thin film preparation and photoresist coating. The process parameters of a Spin Coater include rotation speed, rotation time, viscosity of the coating liquid, and the position of the liquid drop. These parameters influence the thickness, uniformity, and quality of the coating. Different applications and materials may require different process parameters.

Advantages

The device is characterized by high coating efficiency and ease of use.

Coating speed and time can be adjusted in multiple segments with stepless control.

The electrical circuitry is reliable, and the motor operates smoothly, with a particularly high torque that outperforms similar products.

The vacuum chuck uses an electromagnetically controlled air circuit, making it suitable for assembly line processes where a single air pump can operate multiple Spin Coaters simultaneously, improving efficiency.

Features

Coating Uniformity

The Spin Coater uses centrifugal force to evenly distribute the coating liquid on the substrate surface, achieving high-quality thin films or coatings. This uniformity is crucial for many applications, such as lithography processes.

Process Controllability

Spin Coaters typically offer a wide range of adjustable parameters, such as rotation speed, rotation time, and coating position. Operators can adjust these parameters according to specific requirements to achieve the desired coating effect and film thickness.

Wide Application

Spin Coaters are not only suitable for photoresist coating but can also be used for applying various other types of adhesives, liquid materials, or solutions, such as polymer coatings and thin film preparation in different fields.

Rotation Speed Range

Spin Coaters usually offer a wide range of rotation speeds, adjustable from low to high, to meet the requirements for different coating thicknesses and uniformity.

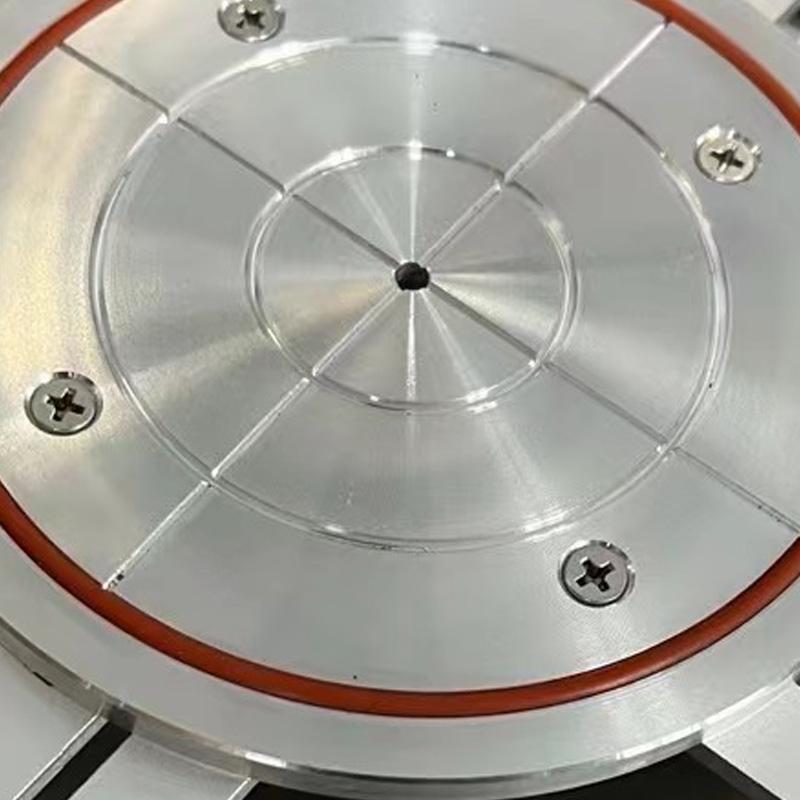

Vacuum Chuck

To ensure the stability of the substrate during the spin coating process, Spin Coaters are typically equipped with a vacuum chuck system to securely hold the substrate in place on the platen.

Automatic Control

Many Spin Coaters provide automatic control options, allowing users to preset coating parameters through programming, thereby enabling automated coating processes.

Principle

The operating principle of a Spin Coater involves dropping the coating liquid onto a rotating substrate. As the substrate spins, the centrifugal force causes the liquid to spread evenly across the surface, forming a thin film or coating. The rotation speed, duration, and viscosity of the coating liquid are crucial factors that affect the thickness and uniformity of the film or coating.

2ac-12/01

2ac-12/01