Plastic Shore Durometer LX-D-2 Hypertherm Plastic Shore D Hardness Gauge Plastic product hardness testing

SE-

LEEB LX-D Shore Durometer Measurement range 20~90HD$ 196.00

LEEB LX-D Shore Durometer Measurement range 20~90HD$ 196.00 -

SUNDOO LXB-D Rubber and Plastic Shore Durometer Dual Pointer Type D Shore Durometer$ 175.00SE

SUNDOO LXB-D Rubber and Plastic Shore Durometer Dual Pointer Type D Shore Durometer$ 175.00SE -

SUNDOO LX-D Shore Durometer vulcanized rubber and plastic products hardness testing$ 170.00SE

SUNDOO LX-D Shore Durometer vulcanized rubber and plastic products hardness testing$ 170.00SE -

Pointer Shore Durometer LX-D Hypertherm Type D Shore Durometer High Hardness Pointer$ 157.00SE

Pointer Shore Durometer LX-D Hypertherm Type D Shore Durometer High Hardness Pointer$ 157.00SE -

TQC LD0551 Shore durometer type D, Dial-Type portable Shore durometer$ 1022.00SE

TQC LD0551 Shore durometer type D, Dial-Type portable Shore durometer$ 1022.00SE

HBO LX-D-2 Shore Shore DuroMeter (double needle)SPEC

HBO LX-D-2 Shore Shore DuroMeter (double needle)Details

HBO LX-D-2 Shore Shore DuroMeter (double needle)Packing list

- SKU

- NB001390

- Pin stroke range

- 0~2.5mm

- Measurement range

- 0~100HD

- Measurement range

- 20~90HD

- measurement error

- ±1HD

- Pin end pressure

- F = 445HD (mN); HD is the Shore D hardness gauge Hardness reading

- Weight

- 0.16kg

- Crimping head size

- SR0.1mm

- Dimension

- 112*60*25mm

product description

Haibao LX-D-2 Plastic Shore Hardness Tester is a double-pointer D-type Shore Hardness Tester, which can be used for hand-held testing, or can be purchased separately for testing with the same type of test bench. LX-D-2 Plastic Shore Hardness Tester is used to measure the hardness value of plastic products, vulcanized rubber, plastic test pieces and other products. It is produced and designed according to various international and national standards.

When the LX-D-2 Plastic Shore Hardness Tester is used to test plastic samples, the test shall be carried out in accordance with the relevant provisions of GB/T2918-1998 "Standard Environment for Condition Regulation and Testing of Plastic Samples". The recommended range of measurement is 20-90HD.

Product Structure

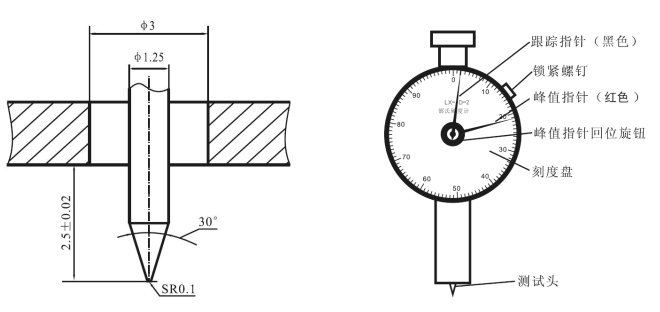

LX-D-2 plastic Shore Hardness Tester is composed of test head, dial, peak pointer return knob, peak pointer (red), locking screw, tracking pointer (black) and other parts. The specific size and structure diagram are as follows:

Pre-test inspection method

1. Before use, check whether the pointer of the LX-D-2 plastic Shore Hardness Tester is pointing to the zero position in a free state (if the pointer slightly deviates from the zero position, you can loosen the compression screw at the upper right corner, and turn the dial to align with the zero position , and then tighten the compression screw); if the peak pointer value deviates from the zero position, you should turn the peak pointer return knob first, and put the peak pointer close to the right side of the tracking pointer.

2. When the LX-D-2 plastic Shore Hardness Tester is pressed on the reference plane to check the zero position, because the hard indenter is easy to press into the reference plane under heavy load, it cannot read accurately, so it needs to be pressed on the reference plane. Put on the standard gauge block. When operating, hold the LX-D-2 plastic Shore Hardness Tester, align the indenter with the center hole of Lingkuai, and press down the plastic Shore Hardness Tester. When the pressing foot of the LX-D-2 Hardness Tester is pressed with the special gauge block and the reference surface, the Hardness Tester should display 10±0.5HD (the thickness of the gauge block is 2.25±0.003mm, which is equal to the indentation depth when the Hardness Tester is pressed into 10HD) , if it cannot be displayed accurately, the Hardness Tester cannot be used.

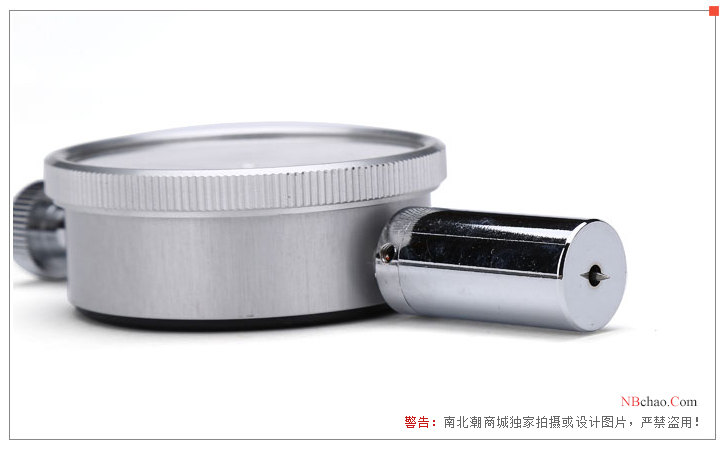

Pictures

- 1DIN 《Shore A and Shore D hardness testing of rubber》

- 2ASTM -2022《Standard Test Method for Indentation Hardness of Elastomeric-Type Sealants by Means of a Durometer》

- 3JJG 2006-1996《Measuring Instruments of Hardness Testing on Shore Scale D》

- 4JJF 2075-2023《 Calibration Specification for International Rubber Hardness Degrees Testers(Scales N,H,L)》

- 5JJF 2074-2023《Calibration Specification for International Rubber Hardness Degrees Reference Blocks(Scales N,H,L)》

- 6JC/T 2570-2020《Color sand flooring materials》

- 7JB/T 8284-1999《Specifications for D - type Shore hardness testers》

- 8KS MISO 868-2001《Plastics and Ebonite - Determination of Indentation Hardness by Means of a Durometer (Shore Hardness)》

- 9GB/T 603-2023《Chemical reagent—Preparations of reagent solutions for use in test methods》

- 10GB/T 18173.3-2014《Polymer water-proof materials―Part 3:Hydrophilic expasion rubber》

LX-D-2

LX-D-2