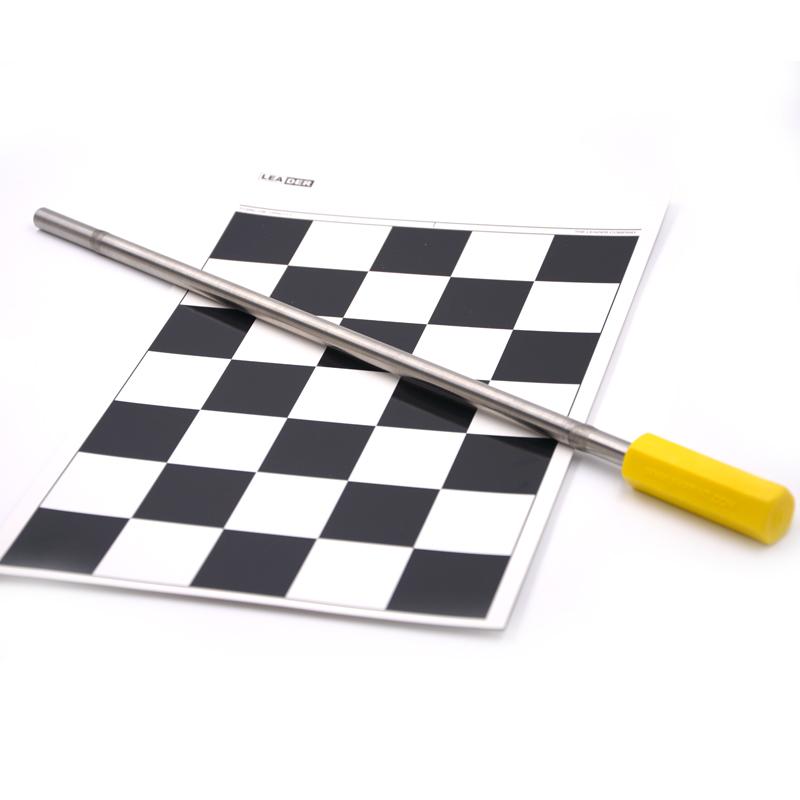

UK RK KHC.11.1 long coating rod WFT 6μm yellow rubber head No. 1 rod

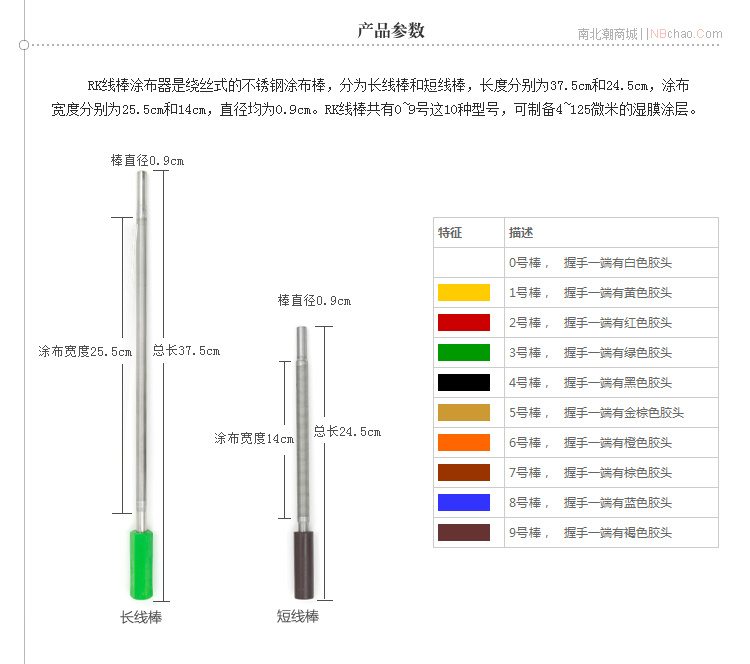

SEWire-wound, wet film thickness 6μm, diameter 9mm, Total length 375mm, application width 255mm, grip width 60mm, material stainless steel. One-handed film

$168.00/piece

PromotionLoading...

Coupon

Model:

Similar products

-

US RDS 3 #3/8 "Mayer Rods coating bar 6.9μm Length 400mm$ 162.00SE

US RDS 3 #3/8 "Mayer Rods coating bar 6.9μm Length 400mm$ 162.00SE -

US RDS 3 #1/4 "inks coating bar film thickness 6.9μm rod diameter 6.35mm$ 156.00SE

US RDS 3 #1/4 "inks coating bar film thickness 6.9μm rod diameter 6.35mm$ 156.00SE -

RDS 3 #1/4 "wire-wound Applicator rod film thickness 6.9μm Wire diameter 0.08mm$ 156.00SE

RDS 3 #1/4 "wire-wound Applicator rod film thickness 6.9μm Wire diameter 0.08mm$ 156.00SE -

Japan OSP-05/250 thread coating bar WFT 5μm length 250mm$ 153.00SE

Japan OSP-05/250 thread coating bar WFT 5μm length 250mm$ 153.00SE -

Japan OSP-08/250 formed coating rod WFT 8μm length 250mm$ 153.00SE

Japan OSP-08/250 formed coating rod WFT 8μm length 250mm$ 153.00SE

RK KHC.11.1 Applicator rodSPEC

RK KHC.11.1 Applicator rodDetails

RK KHC.11.1 Applicator rodPacking list

- SKU

- NB000141

- Production process

- Wire-wound

- WFT

- 6μm

- diameter

- 9mm

- Total length

- 375mm

- Application width

- 255mm

- grip width

- 60mm

- material

- stainless steel

KHC.11.1

Applicator rod

Wire-wound, wet film thickness 6μm, diameter 9mm, Total length 375mm, application width 255mm, grip width 60mm, material stainless steel. One-handed film

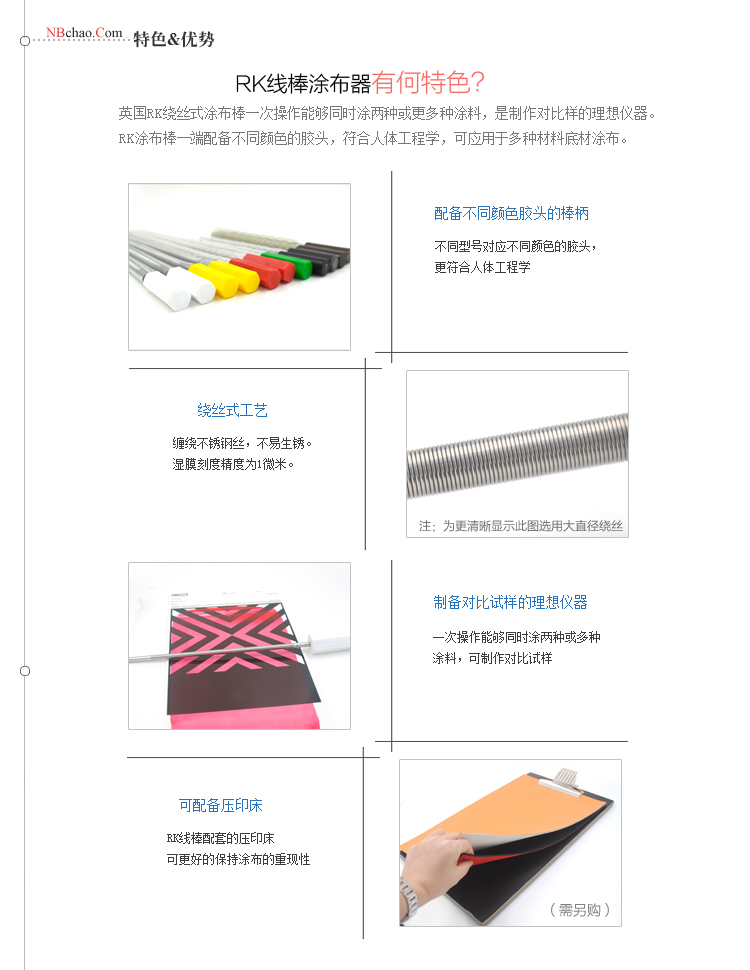

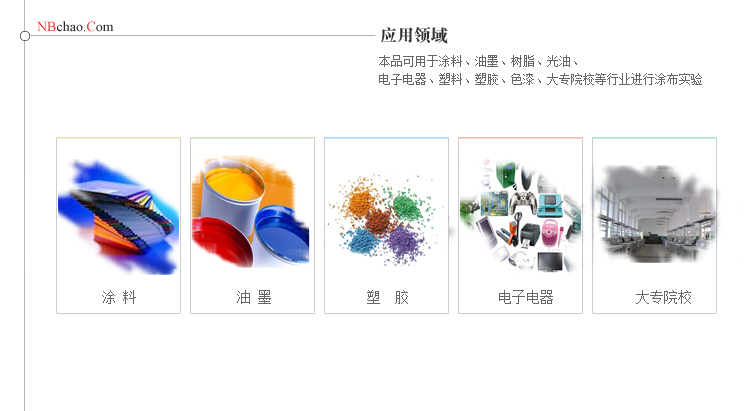

The British RK1 coating rod is a coating rod with a thickness of 6 microns. It has a yellow plastic handle on one end. It is a wire-wound stainless steel coating rod. It is divided into two lengths: 24.5 cm and 37.5 cm. The coating width is 25.5 cm respectively. cm and 14cm. RK coating rod is a high-end brand of coating rod. It is an ideal instrument for preparing comparative samples. Different models of coating rods have different handles in different colors. There are 10 models in 10 colors. The prepared wet film thickness Coating range from 4 to 120 microns.

Optional

| |

|  |

Note: Click on the accessory image to view product details.

FAQ

QWhat is the effective Spreader width of RK1 Mayer Rods in mm?

A

Hello, the width of the Spreader is 25.5cm.

QCan this coating rod be prepative of multi-layer ultra-thin film?

A

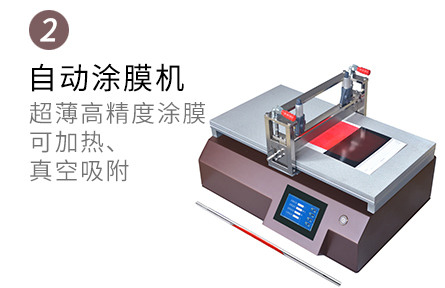

The wire rod can be prepared for 1.5 micron ultra-thin film. Everyone must know it, but another advantage of it is multi-layer film, which is much better than I-shaped film applicator. But multi-layer film tests the flatness of the previous layers of film drying. Generally, the film thickness (such as less than 10 microns/layer) is too thin to control. The wire rod with Film Applicator is a very good solution, eliminating the problem of uneven pressure and speed of hand scraping.

QI want to do a test on the GB/T13217.1 standard. Is this Applicator rod okay?

A

Sure

Knowledge

- 1Bar Spreader Technology: Principles, Applications and Advantages over Miscellaneous coating methods

- 2Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

Standard

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2GB/T 7044-2022《Colour carbon black》

- 3HG/T 5370-2018《Waterborne coatings for bicycles》

- 4HG/T 3951-2007《Water based colorants for architectural coatings》

- 5GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 6HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

- 7ASTM D4147-2023《Standard Practice for Applying Coil Coatings Using Wire-Wound Drawdown Bars》

- 8GB/T 13217.1-2009《Test method for colour of liquid ink》

- 9GB/T 13217.7-2009《Test method for adhesion to substrate of liquid ink with tape》

- 10GB/T 13217.1-2009《Test method for colour of liquid ink》

KHC.11.1

KHC.11.1