TQC SP1880 Impact Tester meets ISO6272 and ASTMD2794 standards

SE-

JINGKELIAN ZCJ High-Duty Impact Tester$ 577.00SE

JINGKELIAN ZCJ High-Duty Impact Tester$ 577.00SE -

Impact Tester TQC SP1895 coating imapct Tester ASTM G14$ 5211.00SE

Impact Tester TQC SP1895 coating imapct Tester ASTM G14$ 5211.00SE -

Falling ball impact test instrument, Dutch TQC SP1891 standard ISO 6272-1 and ASTM D2794$ 4545.00SE

Falling ball impact test instrument, Dutch TQC SP1891 standard ISO 6272-1 and ASTM D2794$ 4545.00SE -

Impact Tester TQC SP1890 meets ISO 6272-1 standard$ 4141.00SE

Impact Tester TQC SP1890 meets ISO 6272-1 standard$ 4141.00SE -

MODERNER ZCJ Heavy-duty impact Tester for impact testing and penetration testing of various coatings for construction

MODERNER ZCJ Heavy-duty impact Tester for impact testing and penetration testing of various coatings for construction

TQC sheen SP1880 Impact test instrumentSPEC

TQC sheen SP1880 Impact test instrumentDetails

TQC sheen SP1880 Impact test instrumentPacking list

- SKU

- NB001425

- Drop Weight Mass

- 1000g

- Striker Diameter

- Φ15.9mm、Φ12.7mm

- die base aperture

- Φ16.3mm

- Standards

- ISO 6272-2:2002、ASTM D 2794:2004、JIS K5600-5-3:1989、EN 12206-1:2004、EN 13523-5:2001、AAMA 2605-05、Qualicoat 2006、Qualisteelcoat 2008

- Maximum test plate thickness

- 45mm

- Bubble level

- Built-in base

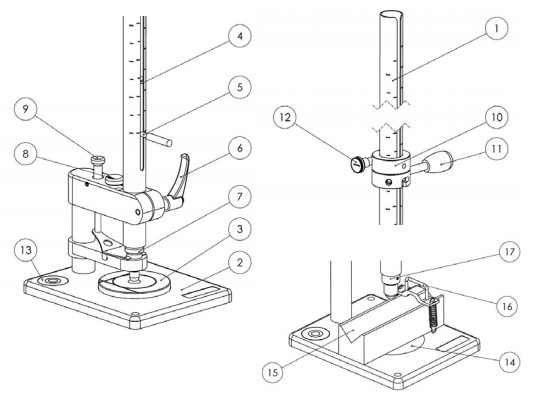

Overview of SP1880 drop weight impact testing machine

The Dutch TQC SP1880 drop weight impact testing machine is a special testing equipment used to test the impact resistance and flexibility of coatings. The SP1880 drop weight impact testing machine has dual scales and a special indicator to ensure that the distance of each impact test is in compliance with the standard. Additionally, for correct positioning, a level is built in.

The maximum test plate thickness of the SP1880 drop weight impact testing machine is 45mm.

SP1880 drop weight impact testing machine application standards

SP1880 drop weight impact testing machine complies with ISO 6272-2:2002, ASTM D 2794:2004, JIS K 5600-5-3:1989, EN 12206-1:2004, EN 13523-5:2001, AAMA 2605-05, Qualicoat 2006, Qualisteelcoat 2008 and other standards.

* The standards that meet the requirements depend on the type of impact testing machine, and other standards can be applied by changing the device combination.

Indirect type impact operation method

1) Check whether the SP1880 drop weight impact testing machine is placed horizontally, whether all components are installed correctly and a punch of appropriate diameter is selected.

2) Press the red button to raise the punch and place the test sample on the mold base.

3) Gently lower the weight onto the punch and adjust the guide tube. The 0 mark on the guide tube should be kept level with the bracket of the drop weight.

4) Make sure that the punch can be raised when the red button is pressed and the drop weight can slide freely on the pipe.

5) Adjust the height limit ring, and adjust the weight to the corresponding scale line in the conduit according to the height required for the test.

6) Raise the drop weight and lock it with the release clamp.

7) In a safe state, release the release clamp to allow the weight to fall.

8) Press the red button to take out the test sample.

9) Check the coating.

10) The operation test can be repeated according to the actual situation.

SP1880 drop weight impact testing machine display diagram

Differences in functional structure diagram of TQC series drop weight impact testing machine

| serial number | Part Name | SP1880 | SP1890 | SP1891 | SP1895 |

| 1 | catheter | â | â | â | â |

| 2, 6, 13 | Base with built-in bubble level | â | â | â | â |

| 3 | 16.3mm die | â | â | ||

| 3 | 27.0mm die | â | â | ||

| 4 | 1kg weight | â | â | ||

| 5 | Heavy hammer | â | â | â | â |

| 7 | 15.9mm diameter punch | â | â | â | |

| 8 | 12.7mm diameter punch | â | |||

| 9 | lift release punch | â | |||

| 10,11,12 | height limit ring | â | â | â | â |

| 14,15,16 | V-notch vise with spring clamp | ||||

| 17 | weight | â | â |

Drop weight impact testing machine functional structure diagram

- 1How to get accurate test results from drop weight impact test?

- 2General Impact Test for Paints and Coatings - ASTM D2794

- 3Discussion on Impact Strength of Paint Film and Its Influencing Factors

- 1JJF 002-2015《Calibration Specification for Film Impact Testers》

- 2SH/T 3022-2019《Design standard for anticorrosion coating of equipment and piping in petrochemical industry》

- 3 10302-2023《Sag resistance polyurethane waterproofing coating》

- 4ASTM 《Standard Specification for Aluminum Particle-Filled Basecoat/Organic or Inorganic Topcoat, Corrosion Protective Coatings for Fasteners》

- 5JT/T 821.1-2011《Anti-corrosive coatings for concrete bridge surface.Part 1: Solvent based coatings》

- 6DL/T 2308-2021《Technical specification for conductive anticorrosion coating for grounding in power engineering》

- 7JG/T 224-2007《Anticorrosive coatings for building steel structure》

- 8HG/T 5060-2016《Anticorrosive coatings for liquified natural gas (LNG) tanks》

- 9HG/T 4338-2012《High-chlorinated polyethylene anti-corrosion coatings》

- 10 0025-2018《PBC Biological Heavy Anti-corrosion Coating》

SP1880

SP1880