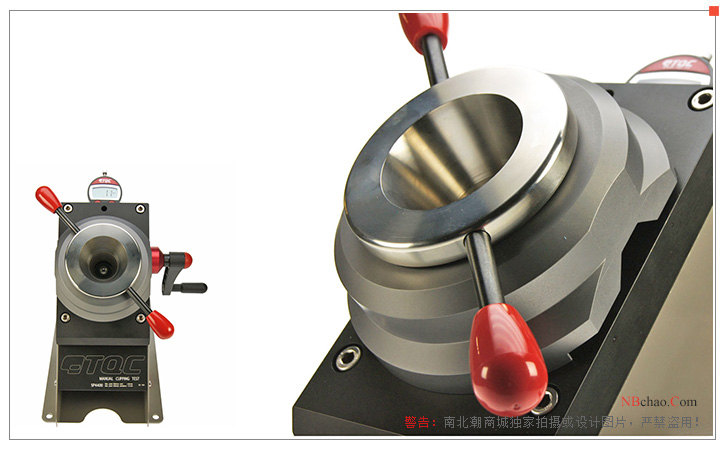

Cupping test machine, TQC SP4400 digital display manual cupping machine

SETQC sheen SP4400 cupping deviceSPEC

TQC sheen SP4400 cupping deviceDetails

TQC sheen SP4400 cupping devicePacking list

- SKU

- NB001429

- Striker Diameter

- Φ20mm

- Die base diameter

- 27Mm (hard steel)

- Impression Accuracy

- ±0.01mm

- Maximum depth of indentation

- 15mm

- Digital resolution

- 0.01mm

- displacement per revolution

- 0.48mm/r

- Test board size

- Maximum width: 95mm; Maximum length: uncertain

- Dimensions

- 313 * 340 (including handle) * 370mm

- Total Mass

- 16kg

- material

- Anode aluminum, stainless steel, spray steel, carbide steel

- Standards

- EN-ISO 1520、BS 3900 E4 sentire

- Speed Accuracy

- +/- 1% of the set speed

- Display

- Blue light illumination, image 100 x 35 cm, 193x64 pixels

- security

- Emergency button with integrated audible alarm

- function

- Push button

- Stroke length

- 0~12 mm

- plate thickness

- ≤1.2mm

The cupping Tester is a special equipment used to test the cracking resistance and separation performance of the coating from the metal substrate at different deformation stages according to the ISO 1520 standard. The SP4400 cupping testing machine has a built-in gearbox to better reduce the manual force required to deform the test plate, and maintain pressure stably applied to the test plate to deform it evenly . The depth of indentation and deformation are displayed in digital form with a resolution of 0.01mm.

The SP4400 cupping Tester is a coating cracking resistance testing instrument approved by Qualicoat, QIB and GSB laboratories.

Application fields of cupping testing machine SP4400

Suitable for steel protection, galvanizing, laboratory, coating industry, paint and other fields testing.

Application standards for cupping testing machine SP4400

This SP4400 cupping testing machine complies with EN-ISO 1520, BS 3900 E4 standards.

Features and advantages of cupping testing machine SP4400

1. Effortless operation

2. Small indentation

3. Left-hand model can be selected according to requirements

Display diagram of cupping testing machine SP4400

Cupping Tester SP4400 operation method

1) Place the test plate in the clamping device of the SP4400 cupping Tester, with the coated side facing up; the thickness of the test plate should not exceed the thickness indicated on the specifications and Tester. Testing a test plate that is too thick may damage the drive shaft and cause deformation making the cupping Tester unusable;

2) Close the clamping device and keep the test plate clamped in place. Do not use too much force when clamping, otherwise when disassembling the test board, the operator will have to use a lot of force to loosen the test board;

3) Open the micrometer;

4) Gently turn the handle upward to raise the pressure head. To achieve an indentation speed of 0.2mm/s, one indentation is required every 2 seconds;

5) The test results are judged either based on the predetermined indentation depth or coating indentation evaluated on the test panel , or based on the depth of the first indentation on the coating;

6) After confirming the test results, return the indenter to the 0 position;

7) Loosen the sample clamping device and take out the sample.

- 1Cupping test and its role in Coating evaluation

- 2Cracking resistance of coatings: Cupping test

- 3Working principle and application of UV coating Cupping testing device

- 1WJ 2669-2005《Specification for cathode electrophoresis paint for shell》

- 2GB/T 22638.11-2023《Test methods for aluminum and aluminum alloy foils—Part 11: Determination of mechanical properties》

- 3GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 4HG/T 2006-2006《Thermosetting powder coatings》

- 5TB/T 2260-1991《Technical conditions for supply of anti-rust primers for railway rolling stock》

- 6HG/T 5370-2018《Waterborne coatings for bicycles》

- 7HG/T 5367.1-2018《Coatings for rail transit vehicles - Part 1: Waterborne coatings》

- 8GB/T 1981.2-2009《Varnishes used for electrical insulation - Part 2: Methods of test》

- 9GB/T 9271-2008《Paints and varnishes standard panels for testing》

- 10ISO 1520-2006《Paints And Varnishes - Cupping Test》

SP4400

SP4400