MODERNER SFJ-500 ground dispersion mixing machine, brushless DC motor 500W

Moderner SFJ-500 Multifunctional mixing and grinding machineSPEC

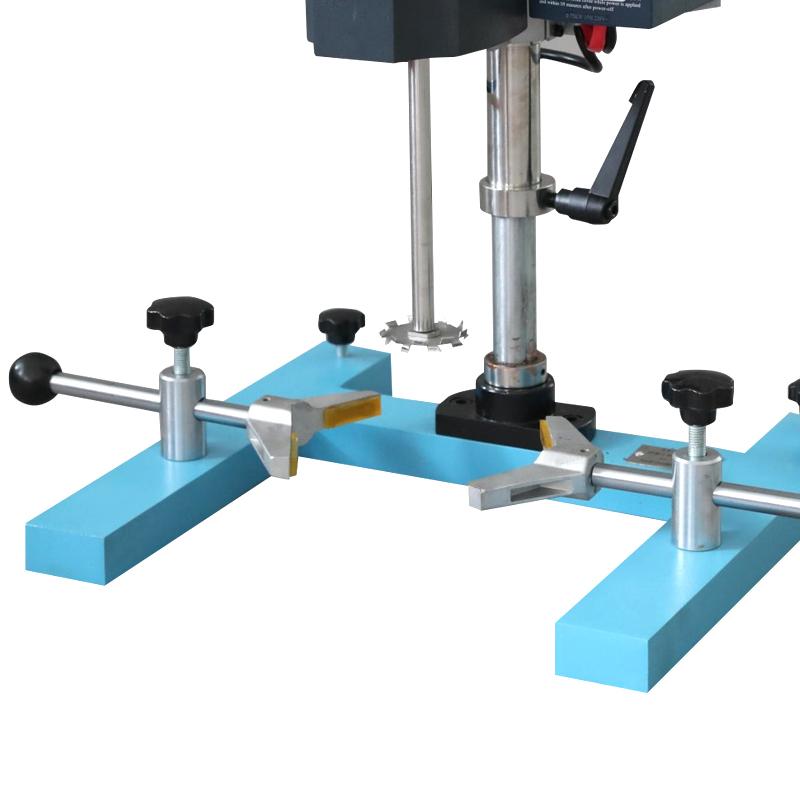

Moderner SFJ-500 Multifunctional mixing and grinding machineDetails

Moderner SFJ-500 Multifunctional mixing and grinding machinePacking list

- SKU

- NB001435

- Motor Power

- 500W

- Speed regulation range

- 50~6000rpm

- Lifting stroke

- 200mm

- Power

- 220V 50Hz/60Hz

- Dimensions

- 450*420*650mm

- Weight

- 25kg

Overview of SFJ-500 grinding, dispersing and mixing multi-purpose machine

MODERNER SFJ-500 grinding, dispersing and mixing multi-purpose machine is an effective equipment for laboratory use. It has three functions: disperser, mixer and Grinder. It uses a brushless DC motor and an extended spindle motor. It operates through vector frequency conversion control and a digital knob. Speed ââadjustment, simple operation, stable and reliable. The mixing speed of the SFJ-500 grinding, dispersing and mixing multi-purpose machine is directly displayed on the display screen, which is clear and intuitive. The use of stainless steel spindle allows the sand grinding, dispersing and mixing multi-purpose machine to have a longer service life and is not prone to rust.

Application

The grinding, dispersing and mixing multi-purpose machine SFJ-500 is widely used in chemical laboratories in industries such as pigments, adhesives, coatings, inks, paints, and paints.

process approach

1) Select a suitable mixing blisk and screw it to the main shaft of the SFJ-500 grinding, dispersing and mixing multi-purpose machine .

2) Install the spindle into the chuck: Pull up the sliding sleeve on the outside of the chuck as far as it will go, and insert the spindle into the chuck hole. After the spindle is inserted to the bottom, rotate relatively until the sliding sleeve on the outside of the chuck can be lowered to the lowest position. At this time, there should be no relative rotation between the chuck and the spindle.

3) Loosen the column locking handle of the SFJ-500 grinding, dispersing and mixing multi-purpose machine , adjust the height of the mixing blisk and the bottom of the barrel (positioning rings can be used), and then raise the main shaft to place the barrel.

4) Lower the spindle to the appropriate position and tighten the column locking handle.

5) Make sure there is no contact between the mixing blade disk and the barrel, and then start stirring.

6) When starting up the SFJ-500 multi-purpose grinding, dispersing and mixing machine , press the "RUN" button first, and then slowly turn the digital speed knob to the speed required for the experiment.

7) After the operation is completed, when shutting down, first use the speed control knob to reduce the speed, and then press "STOP" to shut down, so as to avoid splattering the experimental sample when the speed increases too fast the next time the machine is turned on.

8) The SFJ-500 grinding, dispersing and mixing multi-purpose machine must be cleaned promptly after use for subsequent use.

- 1GB/T 21868.4-2008《Pigments and extenders - Methods of dispersion for assessment of dispersion characteristics - Part 4:Dispersion using a bead mill》

- 2GB/T 21868.3-2008《Pigments and extenders - Methods of dispersion for assessment of dispersion characteristics - Part 3: Dispersion using a high-speed impeller mill》

SFJ-500

SFJ-500