Statistical Coating Thickness Gauge AMITTARI AC-110B Integrated Sensors can store 99 sets of thickness measurement data

SE-

IPRE CT400 magnetic Induction eddy Current Coating Thickness Gauge Measurement range 0~1500μm$ 256.00SE

IPRE CT400 magnetic Induction eddy Current Coating Thickness Gauge Measurement range 0~1500μm$ 256.00SE -

AMITTARI AC-110A built-in thickness probe with resolution of 0.1 μm$ 344.00SE

AMITTARI AC-110A built-in thickness probe with resolution of 0.1 μm$ 344.00SE -

Coating Thickness Gauge AMITTARI AC-110BS Coating Thickness Gauge$ 510.00SE

Coating Thickness Gauge AMITTARI AC-110BS Coating Thickness Gauge$ 510.00SE -

LANDTEK CM8825Fn platings Thickness Measurement Instrument Dual function coating Thickness Measurement Instrument$ 389.00SE

LANDTEK CM8825Fn platings Thickness Measurement Instrument Dual function coating Thickness Measurement Instrument$ 389.00SE -

LANDTEK CM8828 Film Thickness Gauge for automotive coatings$ 389.00SE

LANDTEK CM8828 Film Thickness Gauge for automotive coatings$ 389.00SE

AMITTARI AC-110B Coating Thickness GaugeSPEC

AMITTARI AC-110B Coating Thickness GaugeDetails

AMITTARI AC-110B Coating Thickness GaugePacking list

- SKU

- NB001468

- Measurement principle

- Magnetic Induction + eddy Current

- Measurement range

- 0~1250μm

- margin of error

- ±3%

- Resolution

- 0.1μm|1μm

- Minimum measurement surface

- Φ26mm

- Minimum radius of curvature

- F: convex 1.5mm/concave 25mm; N: convex 3mm/concave 50mm

- thinnest substrate

- 0.3mm

- probe

- F and NF integrated probes

- icon function

- without

- Power Supply

- 2 * AAA 1.5V battery

- Standards

- 1502178、1502360、Gb4956、Gb4957

- Calibrated Certificate

- without

- system language

- Chinese

- Display screen

- 4-Bit digital backlight LCD

- Interface

- RS-232C、USB、Bluetooth

- supporting software

- Yes (optional)

- Machine Weight

- 90G (without battery)

- Machine size

- 130*63*24mm

- Data storage

- 99 sets of data

- statistical function

- Single measurement, continuous measurement

- Operating temperature

- 0~50℃

- Optional accessories

- RS-232C data cable interface, USB data cable output, Bluetooth Data output

- Relative Humidity

- <80%RH

Overview

An Miao AC-110BStatisticalStatisticalThe coating Thickness Gauge is an all-in-one statistical typeThe coating Thickness Gauge can store 99 sets of new measurement data values, which has the characteristics of small measurement error, high reliability, good stability and easy operation, and is an indispensable non-destructive testing instrument for controlling and ensuring the quality of crystal production.AC-110BStatisticalStatisticalCoating Thickness Gauge is to makePortable battery-powered measuring instrument with magnetic induction and eddy current principle. The measurement method conforms to the international national standards Gb4956 and GB4957 for 1502178 and 1502360. It uses a number of professional technologies such as computer technology and non-destructive testing technology to accurately measure the thickness of the coating without damaging the measured body.

Features

* The F-type probe can directly measure the thickness of non-magnetic overlays (e.g., paint, plastic, enamel, copper, aluminum, zinc, chromium, etc.) on the surface of magnetically permeable materials (e.g., iron, nickel). It can be applied to the thickness measurement of electroplating, paint layer, enamel layer, aluminum tile, copper tile, babbitt alloy tile, phosphating layer and paper, and can also be used for thickness measurement of hull paint and attachments of underwater structural parts.

* The N probe can measure the thickness of the insulating covering on non-magnetic metal substrates, such as paint, plastic, and rubber coatings on the surface of materials such as aluminum, copper, zinc, and non-magnetic stainless steel, as well as the anodizing thickness of aluminum or aluminum alloy materials.

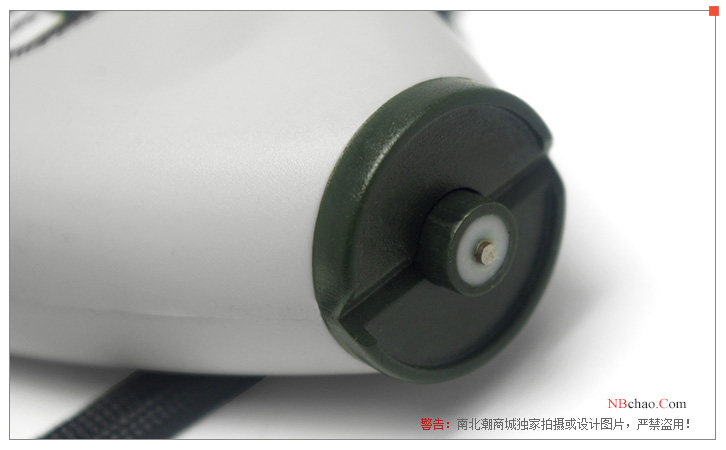

* AC-110BStatisticalStatisticalCoating Thickness GaugeSpring-guided bushing probe with wear-resistant hard metal probeThe head can not only measure on hard or rough surfaces, but also ensure that the probe has a constant compression force and a stable sampling value.

* Wide measurement range and high resolution.

* Automatic memory of calibration values, easy to use.

*Integrated structure, small size, light weight.

* Digital backlit display, no parallax.

* It can store 99 sets of data, and realize the statistical function of the instrument by measuring the average, maximum and minimum values.

* Utilizes optional RS232C software and cable available with PCComputer communication to realize the functions of data collection, processing, analysis and printing.

*rootAC-110BStatisticalStatisticalCoating Thickness GaugeIt is equipped with automatic shutdown to achieve power saving function.

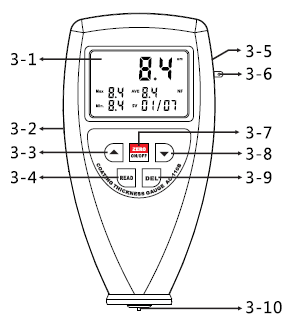

Functional structure diagram

3-1 Display;

3-2 RS-232C interface;

3-3 plus one key;

3-4 Read key;

3-5 battery cover;

3-6 wrist rope buckle;

3-7 Power button;

3-8 minus one key;

3-9 Delete key;

3-10 sensors

Procedure

1) Press the power button lightly, and after turning on the power of the whole machine, it is wonderfulAC-110BStatisticalStatisticalCoating Thickness GaugeAutomatically enter the measurement state and automatically restore the parameter settings before the last shutdown.

2) After confirming that the calibration is correct, the measurement can begin. If there is any doubt about a previous calibration, a second calibration should be performed.AC-110BStatisticalStatisticalCoating Thickness GaugeOnce calibrated, the calibration results are automatically stored in the instrument and do not need to be calibrated again the next time the machine is turned on for measurement, unless there is doubt about the accuracy of the measurement.

3) Press the measuring sensor onto the coating to be measured, and the value on the display is the measured value of the coating to be measured. If necessary, the measured value can be corrected by adding one key or subtracting one key to correct the north and south tides: press plus one key or subtract one key to correct the elbow, and the measuring probe must be lifted, otherwise pressing plus one key or subtracting - key is invalid.

(Note: Since all magnetic coating gauges use the principle of electromagnetic induction; non-magnetic coating gauges use the principle of eddy current, it is important to take care that the probe does not press the body too slowly.) Otherwise, there will be artificial measurement errors. )

4) To take the next step of the measurement, the measurement sensor needs to be lifted to more than 1 cm and then repeat the above steps. thisAC-110BStatisticalStatisticalCoating Thickness GaugeThe measured value of each measurement is automatically stored and the maximum, minimum, average and number of measurements are displayed on the screen.

5) If you want to change the unit of measurement, just tap the power button and hold on until "UNIT" appears on the monitor. (It takes about 6 minutes from the time the power button is turned on to the time the UNIT appears.)

6) If you want to change the measurement mode and realize the conversion between single measurement and continuous measurement, you can also press the power button until AC-110BStatisticalStatisticalcoating Thickness GaugeYou can release the button only when the SC appears on the monitor (it takes about 8 seconds from pressing the power button to the time the SC appears). When measuring at the end of power-on, if there is no "(())" symbol on the monitor (only displayed during measurement), it means a single measurement mode, and the buzzer will sound once every time you measure. If "(())" is displayed all the time, it indicates continuous measurement mode, and the buzzer does not stop during measurement.

Precautions for use

1. In order to reduce the influence of the material of the measuring body on the measurement accuracy, it is recommended to use the uncoated measuring body or the standard test block with the same material as the measuring body as the reference block for calibration.

2、AC-110BStatisticalStatisticalCoating Thickness GaugeAfter the measurement, press the power button to turn off the power of the whole machine. If it is not used for a long time, it is recommended to apply a little grease to the contacts and reference block of the measuring head to prevent rust.

3. The instrument should be protected from violent vibration and impact. Wipe off after useAC-110BStatisticalStatisticalCoating Thickness GaugePut the surface oil stain in the instrument case and store it properly.

4. It is strictly forbidden to knock or collide with the probe so as not to affect the performance of the probe.

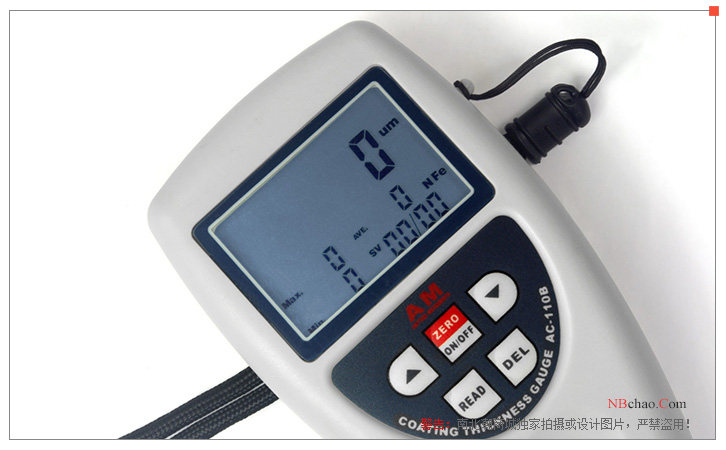

Actual picture of the product

- 1GB/T 44757-2024《Anodizing coating on titanium and titanium alloys》

- 2QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 3NF EN ISO 2808-2007《Paints and varnishes - Determination of film thickness.》

- 4JJG 818-2018《Magnetic and Eddy Current M easuring I nstrument for Coating Thickness》

- 5GB/T 1727-2021《General methods for preparation of coating films》

- 6HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 7HG/T 5367.1-2018《Coatings for rail transit vehicles - Part 1: Waterborne coatings》

- 8ASTM B244-2021《Standard Test Method for Measurement of Thickness of Anodic Coatings on Aluminum and of Other Nonconductive Coatings on Nonmagnetic Basis Metals with Eddy-Current Instruments》

- 9ASTM B499-2021《Standard Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis Metals》

- 10 B530-2014《》

AC-110B

AC-110B