3D three-axis vibration instrument AMITTARI AV-160D simultaneous measurement of three-axis or single-axis vibration parameters

SEAMITTARI AV-160D 3D triaxial vibratorSPEC

AMITTARI AV-160D 3D triaxial vibratorDetails

AMITTARI AV-160D 3D triaxial vibratorPacking list

- SKU

- NB001481

- display

- 4-Position 18mm LCD display for numerical values and measurement status

- Sensors Type

- Three-dimensional piezoelectric accelerometer, that is, set X, Y, Z axis three piezoelectric Sensors into one Sensors

- Accuracy

- ± (5% n + 2) words

- Displacement Measurement range

- 0.001~4.000mm

- Speed Measurement range

- 0.1~400mm/s

- Acceleration Measurement range

- 0.1~400.0m/s²

- Displacement frequency range

- 10Hz~1KHz

- Speed frequency range

- 10Hz~1KHz

- Acceleration frequency range

- 10Hz~10KHz

- Operating Temperature

- 0~50℃

- Relative Humidity

- <90% RH

- output

- 2.0V AC load resistance 10k

- Dimensions

- 140*70*30mm

- Power

- 4X1.5vAAA No. 7 battery

- Weight

- About 130g (without battery)

- Optional accessories

- Headphones, USB data cable, RS-232C cable and software

- shutdown

- 2 modes, manual can shut down at any time, automatic will shut down automatically after 5 minutes of the last keyboard operation

Overview of AV-160D 3D Three-axis Vibration Meter

An Miao 3D Three-axis Vibration Meter AV-160D is a portable digital display 3D three-axis vibrating meter. The sensor used is a three-axis piezoelectric vibration sensor, which has X, Y, Z axes or three axes, and can measure three axes at the same time. Vibration parameters or vibration parameters for a single axis. The 3D three-axis vibratIon Meter AV-160D has the function of bearing condition measurement, which conforms to the international standard ISO2954, and is used to test various mechanical vibrations. The measurement accuracy is ±5%+2 characters.

AV-160D Features and Advantages

* Auto power off function.

* Lightweight and easy to operate, easy to use.

* Wide frequency range, up to 10-10KHz.

* With AC signal output, it is convenient for auscultation and recording.

* It has bearing condition measurement function.

* Comply with international standard ISO2954, GB13823.3, for periodical motion measurement to detect unbalance and deviation of moving machinery.

* Designed for on-site measurement of various mechanical vibrations to provide data for quality control, running time and prior equipment maintenance.

* Three piezoelectric accelerometers with high performance are selected to realize three-dimensional vibration measurement with high accuracy and good repeatability.

* Liquid crystal LCD display, one display can display three vibration parameters (velocity, acceleration and displacement) of one-dimensional vibration at the same time, and can also display a selected parameter of three-dimensional vibration at the same time.

* Optional earphones can be used as a stethoscope.

*Using optional RS232 software and cable, it can communicate with PC computer to realize functions such as printing and statistics.

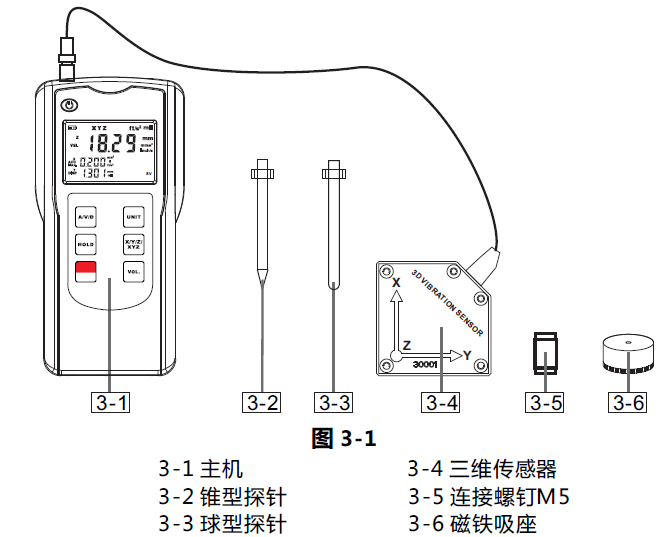

Outline structure diagram

Pictures

Machine vibration classification selection table

| Vibration intensity | Applicable machine category | |||

| Vibration velocity V rms (mm/s) | I | II | III | IV |

| 0~0.28 | A | A | A | A |

| 0.28~0.45 | ||||

| 0.45~0.71 | ||||

| 0.71~1.12 | B | |||

| 1.12~1.8 | B | |||

| 1.8~2.8 | C | B | ||

| 2.8~4.5 | C | B | ||

| 4.5~7.1 | D. | C | ||

| 7.1~11.2 | D. | C | ||

| 11.2~18 | D. | |||

| 18~28 | D. | |||

| 28~45 | ||||

| >45 | ||||

Note: (1) Class I is a small motor (motor less than 15kw, etc.); Class II is a medium-sized machine (motor 15kw~75kw, etc.); Class III is a large prime mover (hard foundation); Class IV is a large prime mover ( Elastic base)

(2) A / B / C / D are vibration levels; A is good, B is satisfactory, C is not satisfactory, and D is not allowed. The measured speed (RMS) values shall be in three orthogonal directions of the bearing housing.

AV-160D

AV-160D