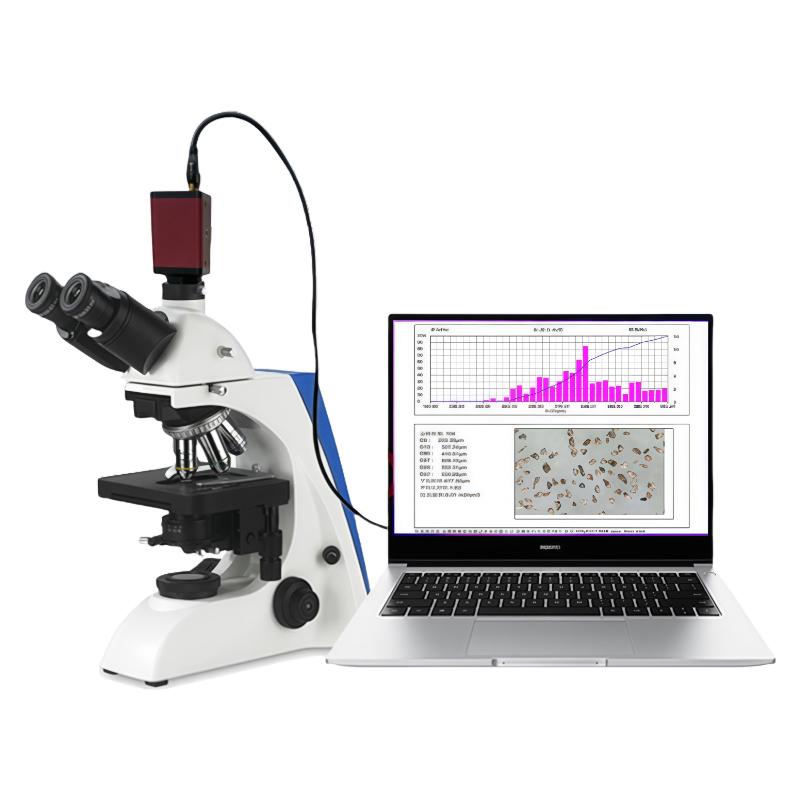

JINGXIN JX-2000A Particle image analyzer test range: 0.5~ 3000μm

SEJingXin JX-2000A Particle image analyzerSPEC

JingXin JX-2000A Particle image analyzerDetails

JingXin JX-2000A Particle image analyzerPacking list

- SKU

- NB014906

- test range

- 0.5~3000μm

- Maximum magnification

- 4000 times

- Maximum resolution

- 0.1μm

- Digital Camera (CCD)

- 3 million pixels

- Microscope

- Configure Transmission Microscope

- Ruler scale

- 10μm

- analysis project

- Particle size distribution, aspect ratio distribution, circularity distribution, etc

- Software operating environment

- Windows XP/ Windows 32位

- interface mode

- USB mode

Introduction

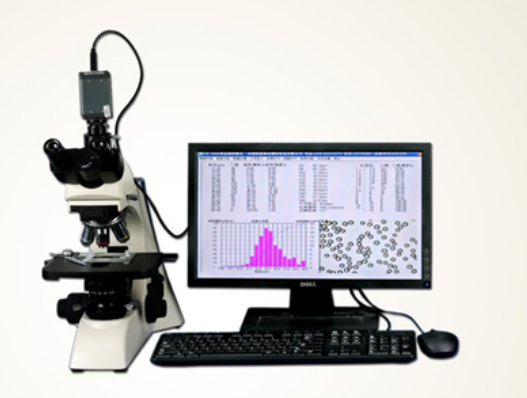

Because powders have different shapes, while testing with a laser particle size analyzer, a JX-2000A image analyzer can be used to achieve a more accurate and intuitive particle size morphology and control and analyze product quality. The system consists of an optical microscope, USB camera, image analysis software, computer, printer and other parts.

The main process of image analysis is: the sample is magnified and imaged through a microscope, and the particle morphology image captured by the camera is transmitted to the computer. The morphology of the powder particles is directly observed on the computer, and the number, area, and number of particles are obtained through calculation and analysis by proprietary software. Distribution data and images such as circumference, diameter, volume, aspect ratio, and short diameter ratio. Data distribution charts such as D10, D50, D90, D97, average particle size, surface area, etc. are also provided. The test results are displayed and saved on the computer, and particle size distribution data and particle morphology pictures can also be printed.

Applicable fields

Powder materials: diamond, silicon carbide, wollastonite, quartz powder, barium sulfate, graphite, lithium cobalt oxide, boron carbide, white corundum, cerium oxide mica powder, carbon powder, metal powder and other mineral powders.

Means and methods for validating other granularity tests.

Characteristics

The industrial-grade camera collects particles at high speed, and the optical microscope magnifies the image. The image is quickly displayed on the computer to directly observe the particle morphology, and special analysis software processes the particle data.

Measuring range: 0.5μmï½3000μm

Interface mode: USB connection.

Plan achromatic objective lens, maximum resolution 0.07 micron, maximum optical magnification 1600 times, maximum printing magnification 4000 times (A4 format).

Distribution data of number, diameter, area, volume, circularity, etc. under two standards of equal area and equal perimeter. At the same time, it provides particle number, D10, D50, D90, average particle size, surface area, aspect ratio and other particle size distribution data. It is equipped with (30) multiple image analysis and processing functions to meet various image processing needs.

Adjust the height, width, brightness, contrast, filtering, filling, etc. of the collected images, improve the analysis resolution, and mark the particle size on the grid. The test results are true and reliable.

The instrument is divided into two models, with the same technical principles and parameters. The JX-2000A particle image analyzer is equipped with a transmission microscope, and the JX-2000B particle image analyzer is equipped with a transmission and reflection microscope. The latter can also be used for various different applications such as ceramics and metals. Observation and analysis of crystal forms on the surface of light-transmitting objects.

Particle morphology images can be saved and printed, and test reports in various formats can also be output. In addition, special software can be designed according to the particularity of powders, such as abrasives, wollastonite, etc.

Image analysis and processing functions

Tone processing: negative image, grayscale, tone adjustment, brightness, contrast adjustment;

Image correction: horizontal mirroring, vertical mirroring, 90 degrees (counterclockwise), 90 degrees (clockwise), rotation, amplification, reduction, Graduation at any ratio, etc.;

Measurement units: Microns, millimeters, centimeters, inches are optional;

Image enhancement: contrast equalization, expansion, corrosion, etc.;

Image processing: image sharpening, edge smoothing, binarization, boundary filtering, analysis target erasure, hole filling, manual erasure, manual connection, particle attribute viewing, setting rulers, grids and other functions;

JX-2000A

JX-2000A