JINGKELIAN QPM plane grinding machine Grinder relative tinting strength and dilution color determination standard test

SEJingKeLian QPM Tablet GrinderSPEC

JingKeLian QPM Tablet GrinderDetails

JingKeLian QPM Tablet GrinderPacking list

- SKU

- NB001530

- Motor power

- 370W

- Grinding disc speed

- 86rpm

- Power

- 220V 50HZ

- Weight

- 40Kg

- Counting range

- 0~999

- Counting range

- 0~999

- Load Weight

- 0.9Kg * 1 / 1.75Kg * 2 / 2.92Kg * 1

- Grinding disc diameter

- 240mm

QPM Flat Mill Overview

JinKeLian QPM flat mill is a kind of special test equipment suitable for the chemical industry such as coatings and pigments. It is a special test equipment for the determination of relative tinting strength and diluted color . In addition, the double-belt transmission motor sheave ensures the accuracy of the transmission data. The components of the QPM flat Grinder are imported high-quality products, which enhance the anti-interference performance.

Features of QPM flat Grinder

1. There is a concave socket on the grinding disc to facilitate the replacement of the grinding disc, without using tools to pry.

2. The total weight of the weight is about 7.32Kg, which is divided into four pieces, including one piece of 0.9Kg, two pieces of 1.75Kg, and one piece of 2.92Kg.

3. The locking structure of the grinding disc bracket is sensitive, convenient and reliable.

4. The motor sheave belt adopts double-belt transmission to ensure accurate transmission speed (the triangular belt is O-shaped, and the belt length is 630mm).

5. The electrical components are all domestic (CN) professional components, which have strong anti-interference.

6. The foot of QPM flat mill is made of oil-resistant rubber material, which has the advantages of shock absorption, non-slip and no damage to the work surface.

7. The weight of the whole machine is about 40Kg, which is suitable for placing on the ordinary work surface (it is very good to place on the cement platform), and the operating height is moderate.

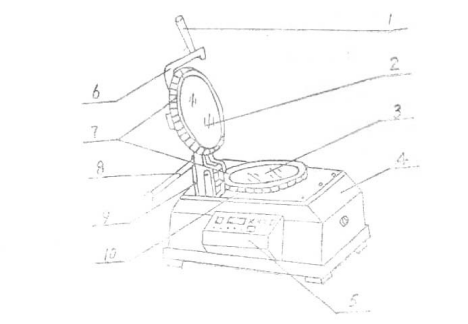

Structural diagram of QPM flat mill

1. Handle hook 2. Upper grinding disc 3. Lower grinding disc 4. Machine cover 5. Electric control box

6. Support frame 7. Fastening ring 8. Exhaust handle 9. Thallium hook 10. Working table

Principle

After the motor of the QPM flat mill is started, the power is transmitted to the reducer. The shaft end of the reducer is equipped with a base for grinding discs, and a sample is placed between the two discs. The required pressure can work after the thallium sheet is installed.

QPM flat Grinder display

- 1GB/T 17001.3-2025《Anti-counterfeiting printing ink—Part 3:Thermochromic anti-counterfeiting printing ink》

- 2ISO 8781-1《Pigments and Extenders - Methods of Assessment of Dispersion Characteristics - Part 1: Assessment from the Change in Tinting Strength of Coloured Pigments First Edition》

- 3ISO 8780-5《Pigments and Extenders - Methods of Dispersion for Assessment of Dispersion Characteristics - Part 5: Dispersion Using an Automatic Muller; (CEN EN ISO 8780-5: 1995)》

- 4ISO 787-17《General methods of test for pigments and extenders — Part 17: Comparison of lightening power of white pigments》

- 5ISO 787-16《General Methods of Test for Pigments and Extenders - Part 16: Determination of Relative Tinting Strength (or Equivalent Colouring Value) and Colour on Reduction of Coloured Pigments - Visual Comparison Method》

- 6HG/T 3239-2009《Technical specifications of plane grinding machine》

- 7HG/T 3854-2006《Determination of mobility of pigments》

- 8HG/T 3853-2006《Determination of resistance to heat of dry power of pigments》

- 9GB/T 7052-2012《Colour carbon black - Determination of flow characteristic》

- 10GB/T 7048-2012《Colour carbon black - Determination of blackness》

QPM

QPM