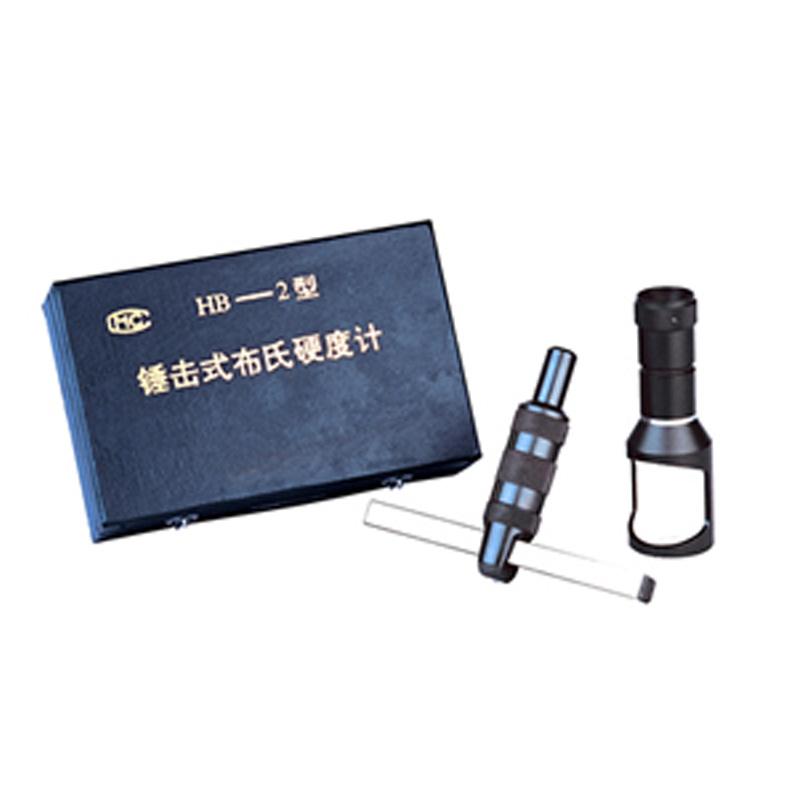

AOLONGXINGDI HB-2 Brinell Hardness Tester

AoLongXingDi HB-2 Brinell Hardness TesterSPEC

AoLongXingDi HB-2 Brinell Hardness TesterDetails

AoLongXingDi HB-2 Brinell Hardness TesterPacking list

- SKU

- NB015419

- Measured object

- The brinell hardness and tensile strength of the steel in the natural state or annealed state, and the brinell hardness and tensile strength of the steel in the refining quenching or quenching and tempering state

- Measured object

- Brinell hardness value of casting, brinell hardness value of brass casting, brinell hardness value of rolling brass, brinell hardness value of red copper, brinell hardness value of tin bronze alloy, brinell hardness value of aluminum alloy casting

Introduction

HB-2 hammered Brinell Hardness Tester is to use a steel ball of a certain diameter after applying an instantaneous impact load, so that the steel ball is trapped in the tested standard hardness test block or the test piece, so as to obtain the indentation, through the measurement of the indentation, obtain the corresponding data, and obtain the hardness value of the test piece by looking up the table. This Hardness Tester is simple in structure, easy to carry and easy to use, and is a Hardness Tester for measuring Brinell hardness in industrial and mining enterprises, production workshops, material warehouses, etc.

Features

●Brinell hardness and tensile strength values of steel in its natural or annealed state (limited to non-austenitic steels)

●Brinell hardness and tensile strength values of steel in refining, quenching or quenching plus tempering (limited to non-austenitic steels)

●Brinell hardness value of casting

●Brinell hardness value of brass castings

● Brinell hardness value of rolled brass

●Brinell hardness value of copper

● Brinell hardness of tin bronze alloy

●Brinell hardness value of aluminum alloy castings

●Before the test, the following preparations should be made, before the test, one end of the large chamfer type of the standard test block (standard hardness test block) is inserted into the spring embedded in the housing between the steel ball indenter, so that the pressure head will press the standard test block on the steel ball.

●On the surface of the tested material, the corrosive layer should be polished to obtain a flat and smooth surface, so that the clear steel ball indentation can be obtained on the test piece during the test, so as to obtain a more accurate value.

- 1How to test the hardness of copper?

- 2Requirements for Casting Hardness in American Standard ASTM and Selection of Sclerometer

- 3What is the Brinell hardness test?

HB-2

HB-2