SMTMF MHBS-3000-AZF Automatic Brinell Hardness Tester

SMTMF MHBS-3000-AZF Automatic Brinell Hardness TesterSPEC

SMTMF MHBS-3000-AZF Automatic Brinell Hardness TesterDetails

SMTMF MHBS-3000-AZF Automatic Brinell Hardness TesterPacking list

- SKU

- NB015551

- Brinell scale

- HBW2.5/62.5 HBW2.5/187.5 HBW5/125 HBW5/750 HBW10/100 HBW10/1500 HBW10/3000 HBW10/250 HBW10/500 HBW10/1000

- test force

- 62.5 (612.9)、 100 (980.7)、125 (1226)、 187.5 (1839)、 250 (2452)、 500 (4903)、 750 (7355)、 1000 (8907)、 1500 (14710)、3000 (29420) Kgf(N)

- Test force Accuracy

- 0.1%. One order of magnitude higher than 1% of ordinary Brinell hardness Testers (more than 1000Kgf)

- Maximum height of specimen

- 400mm

- Load time

- 5~60s

- Hardness testing range

- 8〜650HBW

- execution standard

- GB/T231.2 national standard JJG150 verification procedures

- Indenter - Outer Wall Distance

- 250mm

- Host Weight

- Approx. 300kg

- Power Supply

- AC220+5%,50〜60Hz

- Dimension

- 550*210*750mm

- Workbench size

- 400*370mm

- Sample lift

- Automatic/manual

- For indentation

- automatic

- image focus

- Automatic/manual

- turret

- automatic

- Camera (pixels)

- 3 million

- Indentation measurement

- Manual/automatic

- Hardness value automatically displayed

- automatic

- Hardness value conversion

- National standard/automatic

- Failure value alarm

- automatic

- Hardness statistical analysis

- Yes.

Introduction

MHBS-3000-AZF touch screen automatic Brinell hardness measurement system is mainly used to measure the Brinell hardness of metals and some non-metallic materials according to the <>. This Hardness Tester has high accuracy and high degree of automation, which is suitable for high-end users with large measurement workload or high accuracy requirements.

Features

●The instrument is controlled by microcomputer;

●Automatic lifting of high-precision large worktable;

●Automatic application of primary and main test force;

●Automatic indentation;

●Automatic turret;

● Autofocus;

●Automatic measurement of indentation diameter;

●Large test space, up to 400mm;

●Automatic conversion of national standard/ASTM hardness;

●Automatic alarm of unqualified value;

●Automatically generate customized inspection reports;

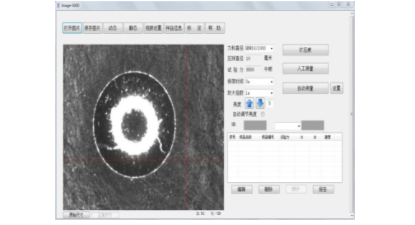

●HB-CCD Brinell hardness measurement system

Main functions

One. Automatic measurement: automatically or manually capture the indentation and measure the indentation diameter and calculate the corresponding Brinell hardness value;

Two. HB2 automatic measurement (German industrial standard DIN1605): automatically or manually measure the indentation diameter of the standard test block and the specimen, and automatically check the table and interpolation to calculate the HB value of the specimen;

Three. Hardness value conversion and effective verification: The system can convert the measured Brinell hardness value HB into other hardness values such as HV, HR, etc.;

Four. Data statistics: the system automatically calculates the average value, variance and other statistical values of the measured hardness;

Five. Alarm of exceeding the standard: automatically indicate the abnormal value, and automatically alarm when the hardness exceeds the specified value;

Six. TEST REPORT: AUTOMATICALLY GENERATE REPORT IN WORD OR EXCEL FORMAT, REPORT TEMPLATE CAN BE CUSTOMIZED;

Seven. Data storage: Measurement data including indentation images and other documents can be stored;

Eight. Other functions: Includes all the functions of the microscopic image processing and measurement system, including image shooting, calibration, image processing, geometric dimensioning, document annotation, album management, and fixed magnification printing, etc.

System features

One. Easy to use: click the interface button to complete all the work; If you need to measure or modify the results manually, you can drag and drop the mouse;

Two. Strong noise immunity: professional and reliable image recognition technology can handle indentation recognition on complex sample surfaces, and two automatic measurement modes to deal with extreme cases;

| Standard Configuration: | ||

| serial number | name | quantity |

| 1 | Fully automatic Brinell Hardness Tester | 1 unit |

| 2 | Fully automatic Brinell hardness measurement system | 1 set |

| 3 | Tungsten carbide ball indenters with diameters of 2.5, 5 and 10mm | 1 bottle each |

| 4 | Standard hardness blocks | 3 pieces |

| 5 | Objective lens (built-in) | 1 set |

| 6 | Power cord | 1 root |

| 7 | Tablet | 1 unit |

| 8 | Industrial Digital Camera (Import, Internal Control) | 1 set |

| 9 | Automatic measurement and image processing system | 1 set |

| 10 | Operation & Maintenance Manual | 1 copy + 1 electronic document |

- 1How to test the hardness of copper?

- 2When to use Brinell and Rockwell hardness tests?

- 3How to test the hardness of copper?

- 4Requirements for Casting Hardness in American Standard ASTM and Selection of Sclerometer

MHBS-3000-AZF

MHBS-3000-AZF