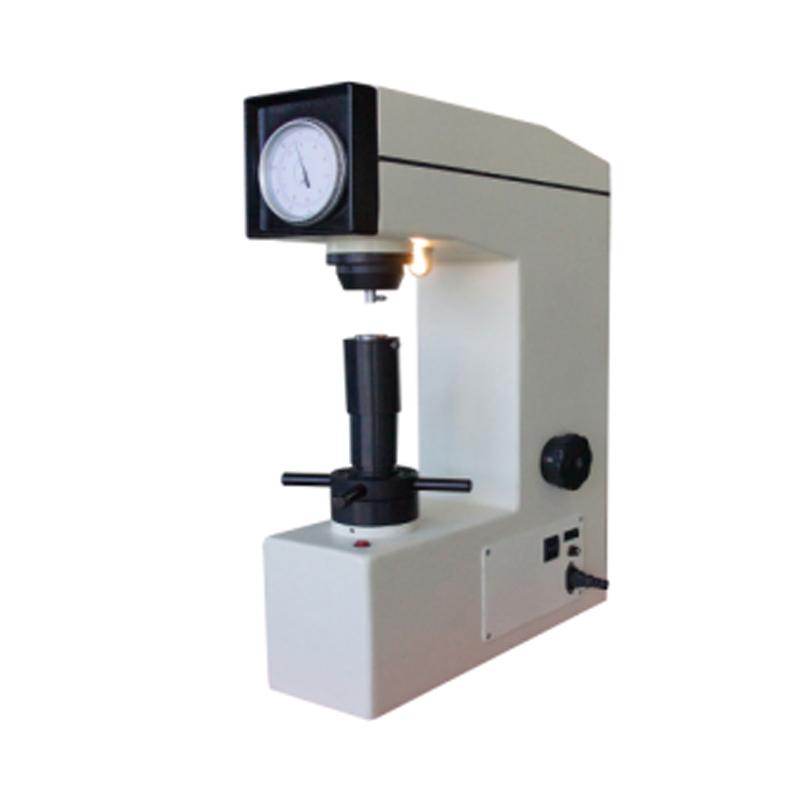

SMTMF HRM-45DT Electric surface Rockwell Hardness Tester Initial test force 29.42N

SMTMF HRM-45DT Rockwell Hardness TesterSPEC

SMTMF HRM-45DT Rockwell Hardness TesterDetails

SMTMF HRM-45DT Rockwell Hardness TesterPacking list

- SKU

- NB015552

- initial test force

- 3kgf(29.42N)

- Total test force

- 15kgf、30kgf、45kgf(147.1N、294.2N、441.3N)

- Hardness testing range

- HR15N:70-94、HR30N:42-86、HR45N:20-77 HR15T:67-93、HR30T:29-82、HR45T:10-72

- Indenter Specifications

- Diamond Rockwell indenter, φ 1.5875mm cemented carbide steel ball indenter

- Hardness reading method

- Dial reading

- execution standard

- ISO 6508、ASTM E18、、GB/T230.2

- Maximum height of specimen

- 170mm

- Distance from the center of the indenter to the fuselage

- 165mm

- Dimension

- 510*212*750mm

- Weight

- 85kg

Introduction

A Hardness Tester is a testing instrument used to determine the hardness of a material, while a hardness test is a means to judge the quality of a metal material or product part. The so-called hardness is the ability of a material to resist the press-in of another object that does not have residual deformation itself under certain conditions. The greater the resistance, the higher the hardness, and vice versa, the lower the hardness.

In the mechanical property test, measuring hardness is the easiest, most economical, and fastest method, and it is also one of the measures to check the quality of products in the process of machinery manufacturing. Since the hardness of metals corresponds to other mechanical properties, most metal materials can be approximated by determining hardness to deduce other mechanical properties, such as strength, fatigue, creep, wear, and internal damage.

Features

Precise, reliable and durable

Sturdy structure with good rigidity

Hardness resolution 0.5 Rockwell units

Dial direct reading: HR15N, HR30N, HR45N, HR15T, HR30T, HR45T

External test force selection knob, easy to operate

Precision oil shock absorber, loading speed adjustable

Large test space allows for larger specimens

Wide range of application, easy to operate, good economy and practicability

Accuracy in accordance with GB/T230.2 ISO 6508 and American ASTM E18

Complete standard configuration, which can meet the test requirements of all scales

External illumination light source, can clearly see the test point

Scope of application

It is suitable for surface quenched steel, material surface heat treatment and chemical treatment layer, copper, aluminum alloy, thin plate, galvanized, chrome-plated, tin-plated materials, bearing steel, cold hard castings, etc.

| Standard configuration | |||

| name | quantity | name | quantity |

| Diamond Rockwell indenter | 1 pc | φ1.5875mm steel ball indenter | 1 pc |

| Large, medium and "V" type test benches | 3 pcs | weight | 1 set |

| Rockwell standard hardness block | 3 pieces | Dust-proof plastic bag | 1 pc |

| Product Certificate of Conformity | 1 serving | Instruction manual for the product | 1 serving |

- 1ASTM -2023《Standard Test Method for Rockwell and Brinell Hardness of Metallic Materials by Portable Hardness Testers》

- 2JJG 2067-2016《Measuring Instruments for Metallic Rockwell Hardness》

- 3JJG 2092-1995《Measuring Instruments for Plastic Rockwell Hardness》

- 4GB/T 713.7-2023《Steel plate,sheet and strip for pressure equipments—Part 7:Stainless steel and heat resisting steel》

- 5GB/T 713.1-2023《Steel plate,sheet and strip for pressure equipments—Part 1:General requirements》

- 6GB/T 42670-2023《Test method for Rockwell hardness of carbon materials》

HRM-45DT

HRM-45DT