SMTMF MHRS-150-Z Automatic Rockwell Hardness Tester tests 15 kinds of rockwell hardness scales

SMTMF MHRS-150-Z Rockwell Hardness TesterSPEC

SMTMF MHRS-150-Z Rockwell Hardness TesterDetails

SMTMF MHRS-150-Z Rockwell Hardness TesterPacking list

- SKU

- NB015564

- initial test force

- 3kgf、10kgf

- main test force

- 15kgf、30kgf、45kgf、60kgf、100kgf、150kgf

- rockwell hardness

- HRA、HRB、 HRC、HRD、HRE、HRF、HRG、HRH、HRK、HRL、HRM、HRP、HRR、HRS、HRV

- LCD display

- Rockwell Ruler, Hardness Value, Force Value Linear dispersion, Depth Linear dispersion, Total test force, Maximum indentation depth, indentation permanent variable, Temperature, Humidity, Operating state, Load holding time, Upper and lower limit setting values GO/NG indication, etc

- add and uninstall method

- Ultra High Response Speed Closed Loop Load Control Technology (Loading, Loading, Unloading)

- Ruler selection

- Touch screen selection

- Ruler conversion

- HR、HB、HV

- Load time

- 0~99s

- Interface

- Built-in printer, RS232 interface

- execution standard

- ASTM E18、ISO6508、GB/T230.2

- Allowable specimen height

- 300mm

- Specimen placement

- Outer surface placement

- Power Supply

- 110/220V AC、60~50Hz

Introduction

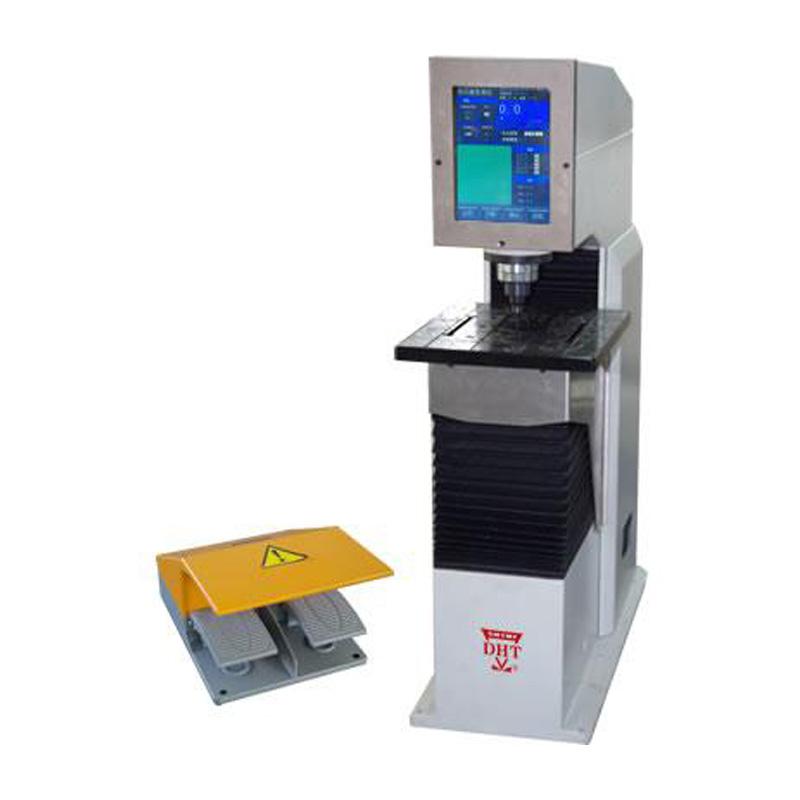

Shanghai Aolong Xingdi Testing Equipment Co., Ltd. newly launched "Aolongxin" large platform automatic Rockwell Hardness Tester MHRS-150-Z, using international professional closed-loop sensor control technology, to achieve fully automatic control and hardness testing process. The loading system adopts a high-precision force value sensor and a central controller to form a closed-loop loop to realize the whole process of microsecond tracking and control of afterburner.

THE BATHYMETRY SYSTEM USES A HIGH-PRECISION DISPLACEMENT SENSOR, WHICH RESULTS IN A MINIMUM HARDNESS VALUE WITH A RESOLUTION OF 0.1 HR. The position of the indenter is fixed, and the hardness test is carried out by the movement up and down the platform. The overall movement of the large platform eliminates the gap generated when the lead screw is lifted, greatly improves the accuracy and repeatability of the test, and also increases the stability and efficiency of the machine. The new foot switch function, one-button measurement, saves a lot of manpower, and is convenient for on-site use.

Features

●Comply with ASTM E18, ASTM E384, ISO 6508, GB/T230;

●The frame structure is firm and rigid;

●Fully automatic closed-loop sensor loading;

●It can test 15 kinds of Rockwell hardness scales;

●High precision, international contrast is less than 0.5HR;

●High-speed step control, extremely fast test speed;

●With foot switch design, the overall automatic lifting of the large platform saves manpower, and one-button automatic measurement;

●High-precision loading system, effectively avoiding force overload, and greatly improving the loading speed;

●The test process curve display can visually display the material characteristics, which is convenient for observation and learning;

●It can be continuously measured in and out of the fixed workbench through the automatic withdrawal function of the indenter;

●The automatic lifting platform and the automatic load initial test force can ensure the stable generation of the force;

●High-definition LCD, touch screen operation, menu-based operation interface;

●Automatic loading and unloading, holding time adjustable;

●GO/NG tolerance judgment;

●Correction of test values of cylinders and spheres;

●The force measurement selection is linked with the hardness scale selection;

●Ruler conversion HR, HB, HV;

● Built-in printer;

| Standard configuration | |||

name | quantity | name | quantity |

| host | 1 unit | Diamond indenter | 1 stick |

| Ф1.588 steel ball indenter | 1 stick | Ф1.588 steel balls | 5 capsules |

| Sample stage | 1 pc | V-shaped stage | 1 pc |

| A scale standard hardness block | 1 piece | B scale standard hardness block | 1 piece |

| C scale standard hardness block | 3 pieces | 15N standard hardness block | 1 piece |

| 30N standard hardness block | 1 piece | 30T standard hardness block | 1 piece |

| 15T standard hardness block | 1 piece | Power cord | 1 root |

| Indenter locking screws | 1 pc | Product Certificate | 1 serving |

| Instruction manual | 1 serving | Dust cover | 1 pc |

- 1ASTM -2023《Standard Test Method for Rockwell and Brinell Hardness of Metallic Materials by Portable Hardness Testers》

- 2JJG 2067-2016《Measuring Instruments for Metallic Rockwell Hardness》

- 3JJG 2092-1995《Measuring Instruments for Plastic Rockwell Hardness》

- 4GB/T 713.7-2023《Steel plate,sheet and strip for pressure equipments—Part 7:Stainless steel and heat resisting steel》

- 5GB/T 713.1-2023《Steel plate,sheet and strip for pressure equipments—Part 1:General requirements》

- 6GB/T 42670-2023《Test method for Rockwell hardness of carbon materials》

MHRS-150-Z

MHRS-150-Z