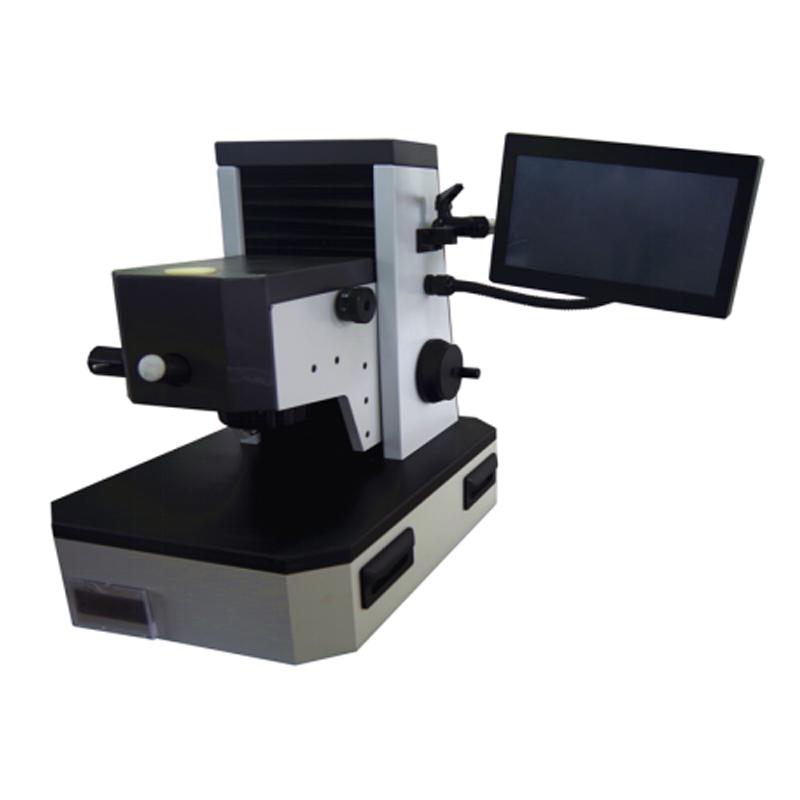

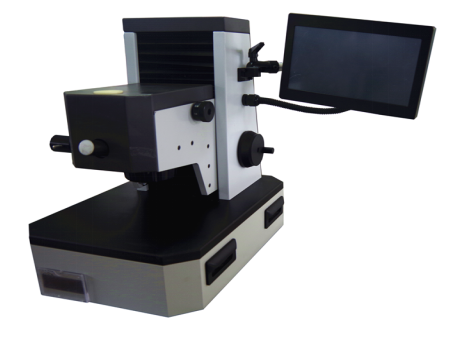

SMTMF JMHVS-1000AT Precision Digital Display Automatic Turret Microscopic Hardness Tester Head Mobile

SMTMF JMHVS-1000AT Precision Digital Display Automatic Turret Microscopic Hardness Tester (Machine Head Mobile)SPEC

SMTMF JMHVS-1000AT Precision Digital Display Automatic Turret Microscopic Hardness Tester (Machine Head Mobile)Details

SMTMF JMHVS-1000AT Precision Digital Display Automatic Turret Microscopic Hardness Tester (Machine Head Mobile)Packing list

- SKU

- NB015590

- test force

- 10gf (0.098N)、25gf (0.245N)、50gf (0.49N)、100gf (0.98N)、200gf (1.96N)、300gf (2.94N)、500gf(4.9N)、1kgf (9.8N)

- execution standard

- GBT4340.1,GBT4340.2,ASTM_E92

- Measurement unit

- 0.0625µm

- Test force application method

- Automatic (loading, retaining, unloading)

- indenter objective lens switching

- automatic

- Microscope magnification

- 100X (for observation) 400X (for measurement)

- Test force holding time

- 5~60s

- X-Y test bench size

- 100*100mm

- Maximum height of specimen

- 210mm

- Maximum width of specimen

- 125mm

- Power Supply

- AC220V+5%,50-60Hz

- Dimension

- 490*320*530mm

- Host Weight

- 60kg

- Hardness testing range

- 5~2500HV

- X-Y test bench itinerary

- 25*25mm

Introduction

JMHVS-1000AT precision touch screen automatic turret microHardness Tester is a new type of microscopic Vickers Hardness Tester using precision mechanical technology and photoelectric technology, Vickers and Knoops hardness testing instrument, the machine has a novel appearance, adopts microcomputer control, and is suitable for determining the microhardness of tiny, thin specimens, surface seepage coating and other specimens and measuring glass and ceramics. The microhardness of brittle materials such as agate and gemstone is a satisfactory hardness testing instrument for material research and testing by scientific research institutions, factories and quality supervision departments.

Features

The intensity of the measuring light source can be adjusted by pressing the button

And can preset the force holding time

The machine adopts a unique indentation measurement conversion and a micrometer eyepiece to measure the reading mechanism at one time

The software has a built-in hardness value conversion table

Easy to use, high measurement accuracy

The Hardness Tester can also be equipped with a photographic device according to the special requirements of the user, and can take pictures of the measured indentation and the metallographic structure of the material

| Standard configuration | |||

| name | quantity | name | quantity |

| Weight shafts | 1 root | weight | 6 pcs |

| Cross test bench | 1 pc | Sheet clamping table | 1 pc |

| Flat clamping table | 1 pc | Filament blessing table | 1 pc |

| screwdriver | 2 handfuls | Horizontal adjustment screws | 4 pcs |

| 10x micrometric eyepieces | 1 pc | Microhardness block | 2 pieces |

| Spare bulb (6V/12W) | 2 pcs | Spare fuse 1A | 2 pcs |

| Spirit level | 1 pc | Product Certificate | 1 serving |

| Instruction manual for the product | 1 serving |

- 1Learn the basics of Vickers hardness testing

- 2The principle and subdivision type of Vickers Hardness Tester

- 3Specific operation methods of microHardness Tester and image measurement system

- 4Requirements for Casting Hardness in American Standard ASTM and Selection of Sclerometer

JMHVS-1000AT

JMHVS-1000AT