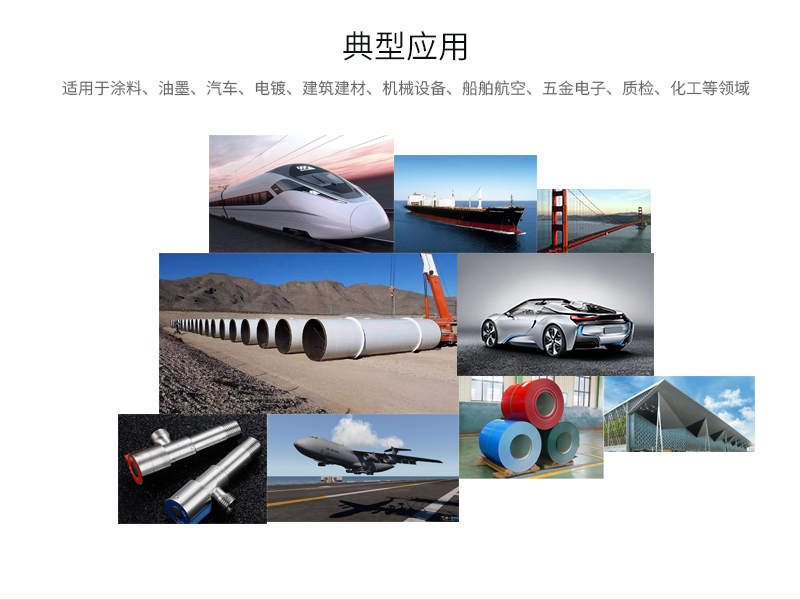

US Defelsko PosiTector 6000 FNDS1 Composite Coating Thickness Gauge measurement paints and galvanized layer thickness

SE-

PHYNIX Surfix SX-FN1.5 dual-use Coating Thickness Gauge 1500μm

PHYNIX Surfix SX-FN1.5 dual-use Coating Thickness Gauge 1500μm -

IPRE CT400 magnetic Induction eddy Current Coating Thickness Gauge Measurement range 0~1500μm$ 254.00SE

IPRE CT400 magnetic Induction eddy Current Coating Thickness Gauge Measurement range 0~1500μm$ 254.00SE -

IPRE CT150 Coating Thickness Gauge Measurement range 0~1500μm$ 234.00SE

IPRE CT150 Coating Thickness Gauge Measurement range 0~1500μm$ 234.00SE -

IPRE CT300 paints film thickness Measurement Instrument magnetic Induction/eddy Current dual-use$ 371.00SE

IPRE CT300 paints film thickness Measurement Instrument magnetic Induction/eddy Current dual-use$ 371.00SE

Defelsko PosiTector 6000 FNDS1 Coating Thickness GaugeSPEC

Defelsko PosiTector 6000 FNDS1 Coating Thickness GaugeDetails

Defelsko PosiTector 6000 FNDS1 Coating Thickness GaugePacking list

- SKU

- NB015814

- Measurement principle

- Magnetic Induction + eddy Current

- Measurement range

- 0~1500μm

- margin of error

- ±1%

- Resolution

- 0.1μm

- probe

- 6000 FNDS Cabled Probe

- statistical function

- Measurement times, MAX Maximum, MIN Minimum, Average, Standard deviation

- icon function

- without

- Power Supply

- 3 * AAA alkaline battery

- Standards

- ISO 2178/2360/2808、PrEN ISO 19840、ASTM B499/D1186/D1400/D7091/E376/G12、BS3900-C5、SSPC-PA2等

- Calibrated Certificate

- Yes.

- Language

- Chinese, English

- Display screen

- LCD screen

- Interface

- USB

- supporting software

- Yes.

- Machine Weight

- 140G (without battery)

- Machine size

- 137*61*28mm

- Data storage

- 1000 Measured values

- Defelsko calibrated standard

- STDS1、STDA1

- Minimum zinc layer thickness

- 0.5 mil (13 um)

- Coating Accuracy

- +(1μm+1%)0~50μm +(2μm+1%)>50μm

- Zinc layer Accuracy

- +(2μm+1%)13~50μm +(4μm+1%)>50μm

- Probe size

- 16mm

- Probe height

- 30mm

PosiTector 6000 FNDS

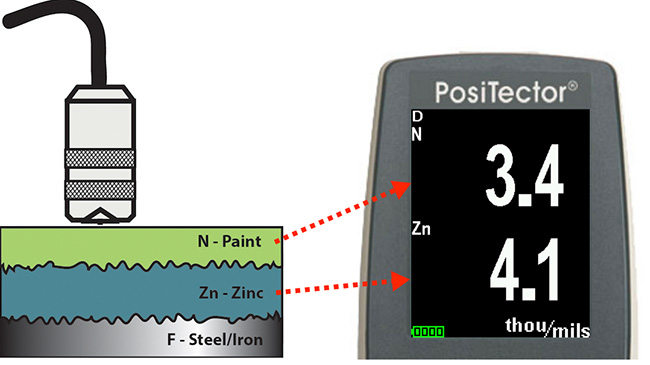

The PosiTector 6000 FNDS probe simultaneously measures the thickness of paint and zinc layers in a composite coating system in a single readout.

Composite coating systems use a combination of two corrosion protection systems – typically painted or powder coated on galvanized steel (thermal, electrical, or zinc-sprayed metal). synthetic corrosion protection due to any individual protection system.

In composite mode, the positector 6000 FNDS uses the principles of magnetic induction (ferrous) and eddy current (non-ferrous) to simultaneously calculate and display individual coating and zinc layer thicknesses. The magnetic induction principle is used to measure the total thickness of the lacquer/zinc layer on a ferrous substrate, while the eddy current Thickness Gauge principle is used to measure the thickness of the paint layer on a non-ferrous zinc layer. The zinc layer thickness is calculated by subtracting the thickness of the paint layer from the total lacquer/zinc layer thickness. The schematic diagram is as follows,

When not available, the gauge is like a traditional ferrous/non-ferrous dual-function gauge (similar to the positector 6000 FNS transducer). It is suitable for measuring non-magnetic properties on steelCoating thicknessThe thickness of the non-conductive coating on a non-ferrous metal substrate.

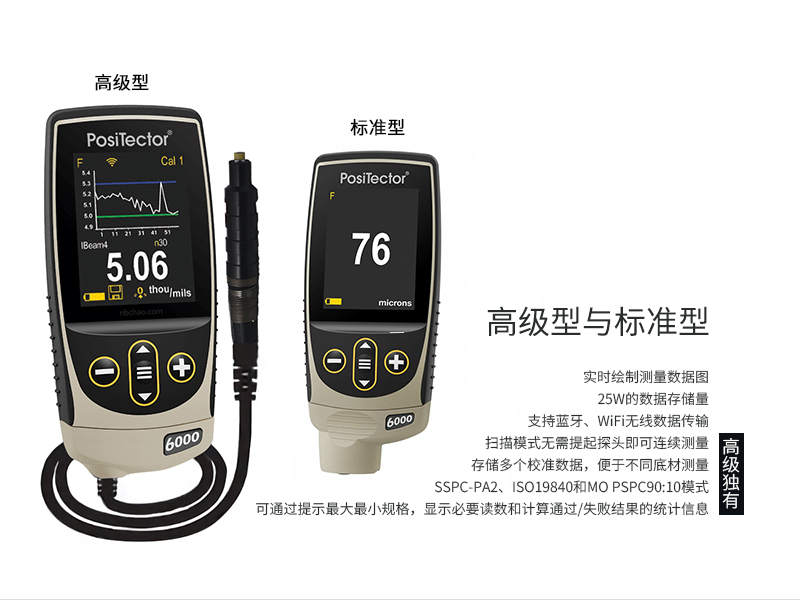

Positicctor Advanced (serial number 730000+) and color LCD are compatible with the Positicctor standard gage. A simple Thickness Gauge update is required.

Recommended reading

★《How do you choose the Defelsko PosiTector 6000 Coating Thickness Gauge?》

★Defelsko PosiTector 6000 Series Coating Thickness Gauge Details (Text Version)

- 1GB/T 44757-2024《Anodizing coating on titanium and titanium alloys》

- 2QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 3NF EN ISO 2808-2007《Paints and varnishes - Determination of film thickness.》

- 4JJG 818-2018《Magnetic and Eddy Current M easuring I nstrument for Coating Thickness》

- 5GB/T 1727-2021《General methods for preparation of coating films》

- 6HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 7HG/T 5367.1-2018《Coatings for rail transit vehicles - Part 1: Waterborne coatings》

- 8ASTM B244-2021《Standard Test Method for Measurement of Thickness of Anodic Coatings on Aluminum and of Other Nonconductive Coatings on Nonmagnetic Basis Metals with Eddy-Current Instruments》

- 9ASTM B499-2021《Standard Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis Metals》

- 10 B530-2014《》

PosiTector 6000 FNDS1

PosiTector 6000 FNDS1