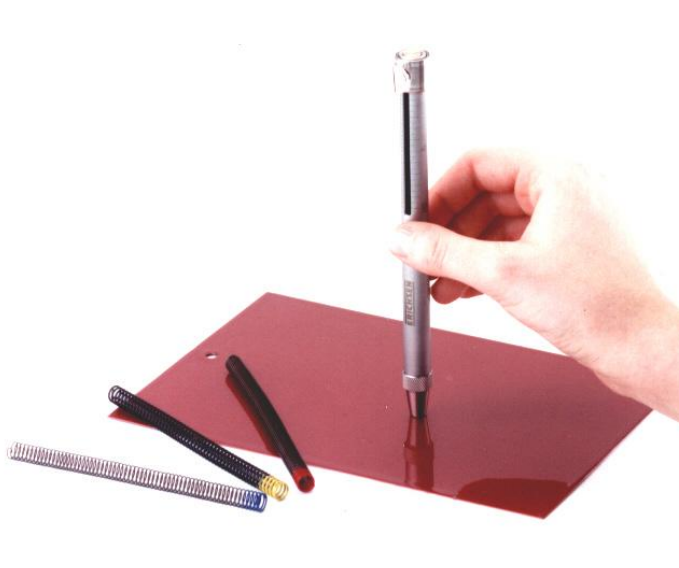

German erichsen318 Hardness test rod Hardness pen 1.0 mm (according to ISO 1518 and DEF)

Erichsen erichsen 318 (1.0mm) Hardness test rodSPEC

Erichsen erichsen 318 (1.0mm) Hardness test rodDetails

Erichsen erichsen 318 (1.0mm) Hardness test rodPacking list

- SKU

- NB016082

- pressure spring

- Spring steel

- Test head material

- tungsten carbide

- Test head diameter

- 1.0Mm (according to ISO 1518 and DEF)

- length

- 160mm

- diameter

- 16mm

- Net Weight

- Approx. 250g

Test principle

The slider allows you to set an estimated or known spring pressure. willErichsen318 hardness test rodPlace it perpendicular to the test surface and draw a straight line of 5~10 mm at a speed of 10 mm/sec. The test head produces a scratch that is only visible to the naked eye. If the spring pressure is too high, the scratches will be clear, and if the spring pressure is too low, no scratches will appear. The required pressure can be controlled each time by locking the slide bar, in Newtons.

Erichsen318 hardness test rodDesigned to measure the hardness of protective coatings. The hardness of paint films and plastic coatings can be accurately measured and recorded by the 318 hardness test rod, and the measured surface can be flat or curved, regardless of size.

The scale engraved on the pen includes 3 pressure ranges:

0-3 N (Blue Mark)

0-10 N (red mark)

0-20 N (yellow mark)

Every oneErichsen318 hardness test rodSprings corresponding to the pressure range have a color code corresponding to the scale.

Maintenance and repairs

A clean instrument produces a clean test result. To clean, loosen the nut and remove the marker. Clean the rod and hole with a soft cloth. In addition, the instrument requires no further maintenance.

Despite the robust construction of the Erichsen318 hardness test rod, the test head cannot tolerate high punches. The box that comes with the instrument provides such a protective feature. When not in use, the slider should be set to the zero position to protect the accuracy of the spring.

- 1Hardness pen of plastic and its application

- 2The Working Principle and Application of Thin Film Hardness Tester

erichsen 318 (1.0mm)

erichsen 318 (1.0mm)