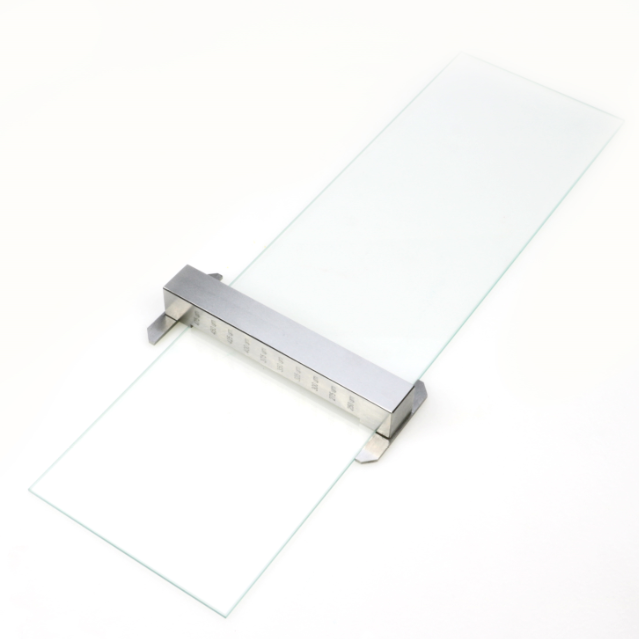

TQC VF2250 sagging resistance Tester Anti-sagging Meter 50~275μm

SETQC sag resistance Tester VF2250 test thickness range of 50~275μm, Sag Applicator made of stainless steel, Spreader total width of 90mm.

$1664.00/piece

PromotionLoading...

Coupon

Model:

Similar products

TQC sheen VF2250 SAG resistance TesterSPEC

TQC sheen VF2250 SAG resistance TesterDetails

TQC sheen VF2250 SAG resistance TesterPacking list

- SKU

- NB016215

- Application width

- 90mm

- Graduation

- 25μm

- Film thickness range

- 50~275μm

VF2250

SAG resistance Tester

The TQC anti-Sag Applicator is designed for anti-sag evaluation. The total film width of 90 mm is divided into 10 gaps in equal parts, and the depth is increased by 25 μm. The spacing between each gap is 1.5mm.

The coating is applied in the same way as that of a standard rod applicator, but the test plate is then lifted and turned at 90 degrees to the horizontal plane, preferably with the thickest coating at the bottom of the sample.

The droop index can be determined by the first track, which does not show signs of sag on the next track below.

The TQC Gloss Anti-Sag Tester has a detachable deflector plate. The deflector ensures direct stretching on glass panels or thicker test panels

Standard:ASTM d4400,ASTM d1084

Serial models

| Model | specification |

| VF2250 | 50~275μm |

| VF2251 | 250~475μm |

| VF2252 | 450~675μm |

| Other parameters | |

| Groove difference | 25μm |

| Coating film width | 90mm |

| standard | ASTM D4400,ASTM D1084 |

FAQ

QWhat is the film width of the VF2250 Sag resistance tester in mm?

A

Hello, the film width is 90mm.

QIs there a JT/T 821.1 standard Sag resistance tester?

A

This TQC Sag resistance tester is fine!

QThere is a Glass plate in the picture. Does TQC's Anti-Sag Meter have a Glass plate?

A

Hello, no, it's just an Anti-Sag Meter.

Knowledge

- 1How to assess the sag resistance of paints and varnishes according to ISO 16862

- 2what is the coating Leveling and Sag resistance

- 3Sag problems and their solutions

- 4Rheological performance of Coating industrial antisagging agent

Standard

- 1 10302-2023《Sag resistance polyurethane waterproofing coating》

- 2 052-2021《Anti-Sag Meter calibrating specification》

- 3GB/T 27806-2011《Tar epoxy anti-corrosion coatings》

- 4HG/T 4340-2012《Epoxy micaceous iron oxide intermediate coatings》

- 5ASTM D7514-2022《Standard Test Method for Evaluating Ink Stainblocking of Architectural Paint Systems by Visual Assessment》

- 6JT/T 821.2-2011《Anti-corrosive coatings for concrete bridge surface.Part 2:Wet-surface tolerant coatings》

- 7JT/T 821.1-2011《Anti-corrosive coatings for concrete bridge surface.Part 1: Solvent based coatings》

- 8ASTM D4400-2018《Standard Test Method for Sag Resistance of Paints Using a Multinotch Applicator》

- 9ASTM D 4400-1999《Standard Test Method for Sag Resistance of Paints Using a Multinotch Applicator》

- 10JB/T 6886-2010《Ventilator painting technical conditions》

VF2250

VF2250