FUSHENG FuSheng TA-100 Single Pole (air-cooled) Piston Air Compressor 950L/7.5kW

FuSheng TA-100 piston machineSPEC

FuSheng TA-100 piston machineDetails

FuSheng TA-100 piston machinePacking list

- SKU

- NB016565

- type

- Single pole (air-cooled) piston air compressor

- compression method

- reciprocating

- exhaust pressure

- 0.8Mpa

- Displacement

- 950L/min

- Bore × number of bars

- Φ100mm*3

- Rotation speed

- 900rpm

- Air interface

- 3/4'’

- Dimension

- 1560*620*1240mm

- Weight

- 360Kg

- Input Power

- 7.5kw

Type A - Air-cooled reciprocating Air Compressor

Heavy load, low speed

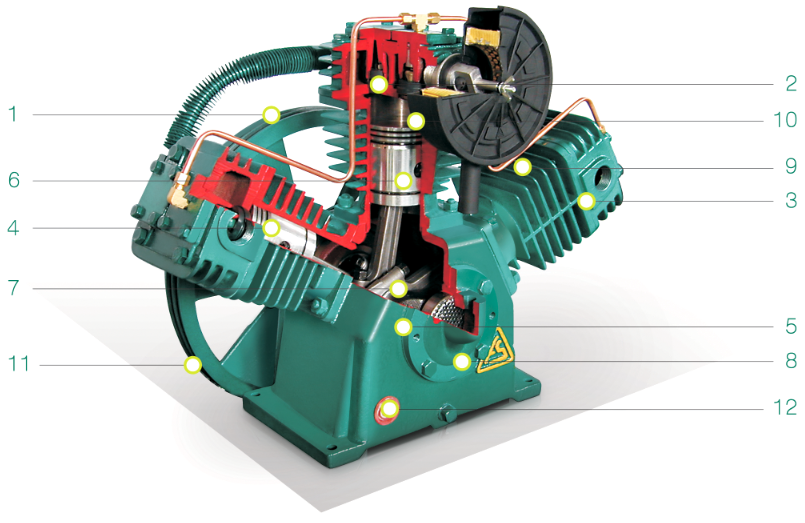

Internal structure of an air-cooled reciprocating Air Compressor

1. Cool the copper pipe

With an effective heat sink, it can effectively reduce the gas temperature and make the air compression efficiency high.

2. Suction and exhaust valves

The valve plate is made of special valve plate steel imported from Sweden. After precision turning, grinding and stress relief, it has good strength, toughness and impact resistance at high temperatures.

3. a cylinder head

Dense streamlined air channels for good heat dissipation

4. a cylinder

The inner diameter is ground by precision CNC machining, which is wear-resistant and durable

5. a crankshaft

It is forged from good steel, with high strength, and all wear parts have been surface hardened, and the wear resistance is very good. With the counterweight, the vibration is small.

6. a piston ring

The compression ring and oil ring are precision machined, and the lubricating oil consumption is very small, and it is not easy to burn the carbon deposit and oil loss of the valve group.

7. a connecting rod

With special machine precision machining, boring and parallelism are kept in the satisfactory design requirements, so that the compressor runs more smoothly and smoothly.

8. a bearing

High-quality imported bearings are used to ensure long-term use.

9. an air filter

Effective filtration of inhaled air has a high degree of sound dampening.

10. Automatic unloading device

The compact and sensitive construction ensures safe operation.

11. Air Compressor pulley

After strict dynamic balance correction, the operation of the Air Compressor is better and smoother.

12. a crankcase

The center hole of the bearing, each plane is processed by the same CNC comprehensive processing machine at one time to ensure balance and verticality.

Product Features

Suction and exhaust valve manifold

Using Swedish special valve steel, after precision turning grinding and internal stress relief, at high temperature, high strength, toughness, impact resistance, long service life.

Cylinder head

The dense streamlined air channel increases the contact surface with the cold air and has a good heat dissipation effect.

piston ring

The compression ring and oil ring have been carefully inspected, the lubricating oil consumption is very small, and the valve group is not easy to carbonize.

cylinder

It is made of high-grade cast iron, and the inner wall is precision polished, which is wear-resistant and durable, and has a long life.

Connecting rod

High-strength ductile cast iron is used for precision machining with special machines, and the parallelism of the boring holes is kept within a certain standard, so that the compressor runs more smoothly and smoothly.

crankshaft

The use of steel steel, after strict material testing, high strength, friction parts are applied surface hardening, good wear resistance. Corrected with detailed calculations

The counterweight minimizes the vibration of the compressor when it is running, with high safety and long mechanical life.

crankcase

The center hole of the bearing is maintained by maintaining a high degree of parallelism, and the processing of each plane is completed at one time, so the error is very small and the quality is stable.

Air Compressor pulleys

After a rigorous power balance test, the machine runs extremely smoothly.

TA-100

TA-100