PhaseII 900-356 High digital display electric Brinell Hardness Tester

PhaseII 900-356 Brinell Hardness TesterSPEC

PhaseII 900-356 Brinell Hardness TesterDetails

PhaseII 900-356 Brinell Hardness TesterPacking list

- SKU

- NB016736

- test force

- 29400N, 14700N, 9800N, 7355N, 4900N, 2452N, 1839N, 1226N,980N, 612.9N

- Test force holding time

- 2S~ 99s, can be set

- Carbide ball indenter diameter

- 10mm, 5mm, 2.5mm

- Measurement range

- 3.18HBW~ 658HBW

- Microscope magnification

- 20X

- Microscope drum Graduation

- 0.005mm

- error of indication

- 2%~3%

- Indication Repeatability

- 2%~3%

- Maximum test space in the vertical direction

- 430Mm (large sample platform) 450mm (small sample platform)

- Horizontal indenter axis from front wall

- 200 mm

- Dimension

- 600*300*1000mm

- Power Supply

- 220/110 V, 50/60 Hz, 4A

- Net Weight

- 205kg

The load cell is used to accurately control the test force;

Direct digital readings;

High sensitivity and accurate value indication;

Suitable for laboratories, workshops, tool rooms, testing rooms, etc.;

Measuring range: 3.18-650HBW;

specification

Innovative closed-loop technology. The Hardness Tester uses a new sensor technology to load the test force through closed-loop sensor control, DC motors, electronic measurement and control units. The accuracy of all force measurement results can reach 0.5%, which solves the overload and underload phenomena that are common in traditional static load and open-loop systems. The elimination of mechanical weights not only eliminates friction problems, but also reduces the impact of vibration excursions on the instrument's measurements.

The weight of the whole machine is reduced by 50% compared to the traditional weight Brinell Hardness Tester.

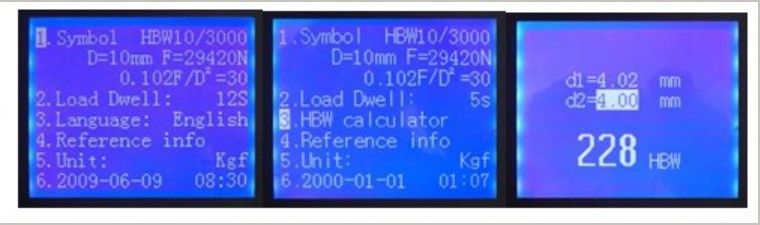

The selection of the test force is done by means of a keyboard and is displayed on the LCD screen.

Fully automated measurements. The Brinell Hardness Tester realizes automatic measurement, and the test force loading, load protection, and unloading are all completed automatically, eliminating the influence of human factors, and greatly improving the repeatability of the indication value.

The retaining time is selected through the screen. The large LCD screen clearly displays the type of indenter, loading force and other test information.

The LCD screen shows how to select the 0.102F/D2 ratio parameter according to the material type and hardness range.

Equipped with a 20X optical microscope to read the Brinell indentation diameter.

The Brinell Hardness Calculator is simple and convenient to calculate hardness values.

- 1Measurement Principle of PhaseII PTG Coating Thickness Gauge

- 2How to test the hardness of copper?

- 3Hardness testing of metal lame plating

- 4How to test the hardness of copper?

- 5When to use Brinell and Rockwell hardness tests?

- 6Which hardness test is suitable for stainless steel?

900-356

900-356