PHASE II 900-391D Vickers Hardness Tester

PhaseII 900-391D Vickers Hardness TesterSPEC

PhaseII 900-391D Vickers Hardness TesterDetails

PhaseII 900-391D Vickers Hardness TesterPacking list

- SKU

- NB016755

- test range

- 1HV~2967HV

- test force

- 0.098N(10g)、0.246N(25g)、0.49N(50g)、0.98N(100g) 1.96N(200g)、4.90N(500g)、9.80N(1000g)

- The maximum height of the sample that can be tested

- 70mm

- The maximum distance from the center of the indenter to the outer wall

- 95mm

- Switching of indenter

- Manual turret

- Test force application method

- Automatic (load/hold/unload)

- Microscope magnification

- 100X、400X

- Test force holding time

- 5~60s

- Minimum Graduation of micrometer drum

- 0.25um

- The size of the cross platform

- 100×100mm

- Movement range of the cross platform

- 25×25mm

- Light source/Power Supply

- 110/220V, 60/50Hz/cold light

- Gross Weight

- 41.5kg

- Net Weight

- 35kg

- Packaging Dimensions

- 425×245×490mm

The Micro Vickers Hardness Tester is a precise testing system for the hardness analysis of metal samples in metallographic laboratories or production halls

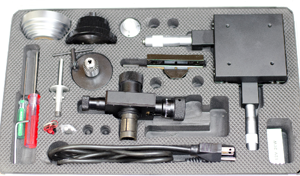

Annex:

Main unit with automatic turret

Word platform

Sheet clamp platform

Filament clamp platform

Flat clamp platform

Camera and adapter lenses

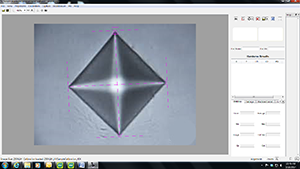

Test the software

USB cable

Optional models

Model: 900-391A Vickers Hardness Tester

Includes camera, adapter glasses and manual measurement software

Model: 900-391B Vickers Hardness Tester

Includes camera, adapter glasses and automatic measurement software

Model: 900-391C Vickers Hardness Tester

Includes camera, adapter glasses, automatic turret and manual measurement software

Model: 900-391D Vickers Hardness Tester

Includes camera, adapter glasses, automatic turret and automatic measurement software

The state-of-the-art PHASE II Micro Vickers Hardness Tester is a state-of-the-art measuring system for the hardness analysis of metal samples in metallographic laboratories or production workshops.

The PHASE II Micro Vickers Hardness Tester is an all-rounder Hardness Tester with a user-friendly system designed for accurate measurement of the depth and gradient hardness of small precision parts, laminated metals, surface coatings, cables and hardened layers. The PHASE II 900-391 series Vickers Hardness Tester consists of an automatic turret, camera, adapter glasses, USB output cable and four optional measurement software. The 900-391 series Vickers Hardness Tester contains test forces from 10g to 1kg.

Following the ASTM E-384/92 Vickers Hardness Tester standard, the 900-391 series Vickers Hardness Tester will provide excellent repeatability. The Micro Vickers Hardness Tester is also capable of measuring Knoop hardness with an optional Knoop indenter. The PHASE II Vickers Hardness Tester is a good product for any environment, with a 5-year warranty and long-term free technical support

- 1Learn the basics of Vickers hardness testing

- 2The principle and subdivision type of Vickers Hardness Tester

- 3What is Vickers Hardness?

- 4Measurement Principle of PhaseII PTG Coating Thickness Gauge

- 5What is the difference between Rockwell hardness and Vickers hardness?

- 6What are the specific advantages of Brinell Hardness Tester testing?

- 7Why use the Vickers hardness test?

- 8Which hardness test is suitable for stainless steel?

- 9Microindentation Hardness Testing Principle and Its Typical Applications

- 10What is the Vickers hardness test? How to test Vickers hardness?

900-391D

900-391D