Muxuan MXR-4D LABOratory Electric Lifting High Shear Mulser All Stainless Steel Rack 20-40L

SEMuXuan MXR-4D Laboratory Electric Lifting High Shear MulserSPEC

MuXuan MXR-4D Laboratory Electric Lifting High Shear MulserDetails

MuXuan MXR-4D Laboratory Electric Lifting High Shear MulserPacking list

- SKU

- NB016918

- Standard throughput

- 20~40L

- Speed range

- 0~3000rpm

- output power

- 4KW

- Lifting method

- Electric lift

- Lifting stroke

- 400mm

- Power

- 220V

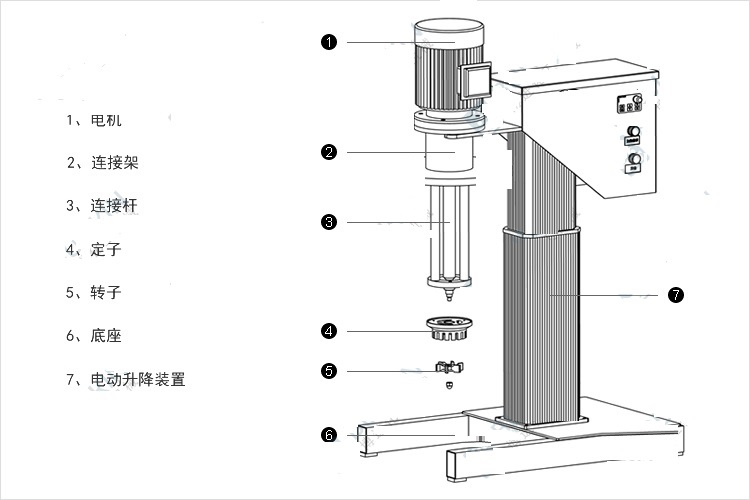

Equipment introduction

The laboratory electric lifting high shear emulsifier is a laboratory equipment designed for small laboratory experiments. Through the method of mechanical external force, the particle size of liquid-liquid and solid-liquid materials is narrowed, so that one phase is evenly distributed into another or multiple phases, so as to achieve the effect of refinement, homogeneity, dispersion and emulsification, thus forming a stable The state of liquid-liquid and solid-liquid dispersion systems. A variety of products with different specifications of working heads can be customized.

Advantages

High efficiency, good product quality

Quickly distribute one phase uniform material to another or multiple materials to achieve the effect of fine homogeneity, dispersion and emulsification, and the product is stable and not easy to delaminate.

High processing precision and long service life

The rotor stator is made of forging material and CNC numerical control processing. The rotor stator gap is small, the shearing fineness is good, the emulsification and dispersion efficiency is high, and the cooling Mixing Tank is selected. The equipment can run for a long time with low temperature rise, and can be automatically emulsified according to the process timing. Shutdown settings.

Modular design, easy maintenance

The equipment is compact in structure, adopts modular design, electric lifting, beautiful atmosphere, labor-saving, free of installation, according to the viscosity of the material, select the appropriate single-layer/double-layer material tank to meet different Operating Conditions.

Strong non-standard

Various types of non-standard products can be customized, such as explosion-proof type, airtight type, manual lifting type, etc. The material can be customized according to requirements such as SS304/SS316L/Hastelloy/titanium-molybdenum-nickel alloy and other materials. At the same time, different emulsifying heads can be customized according to the viscosity of the material to meet the various needs of the laboratory or small batches.

Application

【Material viscosity】:≤8000 cps(mPas)

【Production capacity】:2L-40L

[Applications]: It is suitable for dispersing, emulsifying, and homogenizing product materials in industries such as biology, medicine, food, paint, ink, textile auxiliaries, cosmetics, lubricants, and pesticides.

[Applicable materials]: It can be used in the process of mixing solid and liquid, liquid and liquid to form a solution, colloid, suspension or emulsion; such as juice, soup, dairy products, tissue homogenate, cosmetics, surfactants, Asphalt, emulsifier, oilfield chemicals and other materials.

Applicable process

It is suitable for dispersion, homogenization, emulsification, pulverization, polymerization, suspension and dissolution of small batches and materials.

native features

High-performance motor, strong torque output, capable of dispersing, emulsifying, homogenizing and other functions in the laboratory.

Frequency conversion speed display, claw-type two-way working head, two-way suction, higher emulsification quality.

Models

| model | power | Processing capacity | Lifting stroke |

| MXR-0.75D | 0.75KW | 2-5L | 250mm |

| MXR-1.1D | 1.1KW | 2-5L | 250mm |

| MXR-1.5D | 1.5KW | 5-10L | 300mm |

| MXR-2.2D | 2.2KW | 10-20L | 350mm |

| MXR-4D | 4KW | 20-40L | 400mm |

| Other parameters | |||

| Lifting method | electric | ||

| input power | 220V | ||

| Rotating speed | 0-3000rpm | ||

Principle

The powerful motor of the laboratory homogeneous emulsifier rotates at high speed to form a vacuum between the rotor and the stator, and the material is sucked from the upper and bottom of the rotor and stator. The strong kinetic energy makes the rotor produce a higher linear speed, so that the material is thrown out after strong impact, crushing, centrifugal extrusion, liquid layer friction, and shearing between the rotor and the stator gap. , resulting in strong turbulence. Under the appropriate amount of emulsifier and mature technology, the material undergoes repeated depolymerization, dispersion, homogenization, refinement and shearing to produce a stable emulsion after a certain period of time.

MXR-4D

MXR-4D