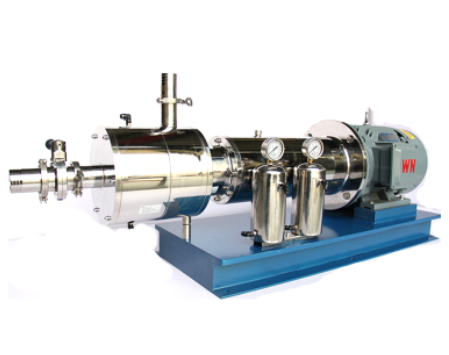

MUXUAN XR-1.5-1 laboratory pipeline emulsification pump

MuXuan XR-1.5-1 Laboratory pipeline emulsification pumpSPEC

MuXuan XR-1.5-1 Laboratory pipeline emulsification pumpDetails

MuXuan XR-1.5-1 Laboratory pipeline emulsification pumpPacking list

- SKU

- NB016920

- Processing Capacity

- 5L

- Speed range

- 0~3000rpm

- Input Power

- 1.5KW

- Power supply Voltage

- 380/220V

- grade

- single stage

Introduction

When the motor rotates at high speed, the multi-layer rotor stator produces strong suction force, and sucks the material into the working cavity, and in the process of the material from the suction port to the discharge port, it is dispersed, sheared and emulsified by the multi-stage and multi-layer rotor stator for many times, and after circulation, continuous dispersion, shearing and emulsification, and finally a stable high-quality product is obtained. It is suitable for mixing, dispersing, dissolving and emulsifying materials with liquid or mutual miscibility.

Scope of application

[Material viscosity]: ≤20000 cps

[Production capacity]: 5-20L for a single time

[Application field]: It is suitable for the dispersion, emulsification and homogenization of product materials in biological, food, coatings, inks, textile auxiliaries, cosmetics, lubricating oils, pesticides and other industries.

[Applicable materials]: solid and liquid, liquid and liquid mixed to form solution, colloid, suspension or emulsion can be used, such as juice, soup, dairy tissue homogenate, cosmetics, surfactants, asphalt, emulsifiers, oilfield chemicals and other more than 1,000 kinds of materials.

Advantages

The operation is simple and convenient

It comes with a circulating barrel, good conveying capacity, convenient solvent self-circulation cleaning, no need to be equipped with an additional transfer pump, double-layer cooling barrel, and low temperature rise of the equipment.

The experimental efficiency is high, and the product quality is stable

The linear speed of the equipment is more than 20m/s, which can quickly distribute one phase uniform material into another or more materials, so as to achieve the effect of refinement, homogenization, dispersion and emulsification, and the final product is stable and not easy to stratify.

High machining accuracy

The rotor stator is processed by forging material and CNC machining center, the rotor stator clearance is very small, the shear limit fineness is good, the emulsification and dispersion efficiency is high, and the double-end mechanical seal design is adopted, which has no leakage and reduces maintenance costs.

Strong non-standard

Materials: SS304, SS316L/titanium alloy/titanium-molybdenum-nickel alloy and other unconventional materials can be customized according to requirements;

Operating Principle

The three-stage emulsion pump in the laboratory adopts a horizontal structure; three groups of rotor stators are installed in the narrow working chamber, and the rotor stator is precisely matched with the coupling; the intermediate shaft is driven by the motor to run at high speed, and the rotor stator forms a vacuum, and the material is sucked into the rotor and stator cavity from the Mixing Tank inlet, and the strong kinetic energy makes the rotor produce extremely high linear velocity, so that the material undergoes strong impact, crushing, centrifugal extrusion, liquid layer friction between the rotor and stator gaps, After the strong shear, it flies out, under the action of a variety of different directional forces, a strong turbulent flow is generated, and the material flows out of the outlet and enters the Mixing Tank circulation, so that the immiscible solid phase, liquid phase, gas phase and other media are evenly fine, dispersed and emulsified in an instant, so that the product can achieve stable and high-quality products.

XR-1.5-1

XR-1.5-1