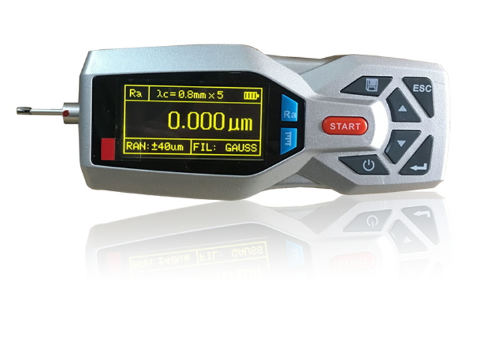

BOTECH botech BC-190 surface roughness meter, imported motor

BoTech BC-190 Surface roughness MeterSPEC

BoTech BC-190 Surface roughness MeterDetails

BoTech BC-190 Surface roughness MeterPacking list

- SKU

- NB017229

- Display mode

- digital display

- Measurement parameters

- Ra、Rz、Rq, Rt, Rp, Rv, R3z, R3y, RzJIS, Rsk, Rku, Rsm, Rmr

- Measurement range

- Ra、Rq:0.005μm~16μm;Rz、R3z、Ry、Rt、Rp、Rm:0.02μm~160μm;Sk:0~100%;S、Sm:1mm

- Resolution

- 0.001

- Error of indication

- ±(7~10)%

- Indication variability

- <6%

- Sampling length

- 0.25mm, 0.8mm, 2.5mm

- evaluation length

- 1L~ 5L optional (L is the sampling length)

- Stroke length

- 17.5mm/0.7inch

- Minimum drive stroke length

- 1.3mm/0.052inch

- filter

- RC、PCRC、Gauss、ISO13565四种

- Measurement profile

- Asperity, ripple, original contour

- Data storage

- 100 original data sources

- Interface

- USB1.0

- Power Supply

- Built-in lithium-ion rechargeable battery/external power adapter

- Dimensions

- 141*55*40mm

- Product Weight

- 400g

- graphics

- Linear dispersion, asperity profile, direct profile

Overview

BC-190 roughness Tester is also known as surface roughness Tester, roughness Tester, roughness Tester and other names. It has the characteristics of high measurement accuracy, wide measurement range, easy operation, easy to carry, stable work, etc., and can be widely used in the detection of various metal and non-metal processing surfaces. The shape is designed with aluminum mold, which is durable and durable, and has remarkable anti-electromagnetic interference ability, which is in line with today's new design trends.

Features

DSP chip is used for control and data processing, with fast speed and low power consumption

It is compatible with ISO, DIN, ANSI, JIS national standards, and is used for surface roughness testing of metal and non-metal processing

Large range, multi-parameter Ra, Rz, Rq, Rt, Rp, Rv, R3z, R3y, RzJIS, Rsk, Rku, Rsm, Rmr

160 μm large range measurement range

128×64 OLED dot matrix display, digital/graphic display, bright and no dead ends

The display is informative and intuitive, and all parameters and graphs can be displayed

The high-speed DSP processor is used for data processing and calculation, which is fast and has higher accuracy

Reliable anti-motor run-off circuit and software design

Built-in lithium-ion rechargeable battery and charging control circuit, high capacity, no memory effect

The remaining battery indicator icon shows the charging process and knows the charging level at any time

The continuous working time is more than 20 hours

Ultra-large capacity data storage, which can store 100 sets of raw data and waveforms

Real-time clock setting and display for easy data recording and storage

It has power-saving functions such as automatic sleep and automatic shutdown

Various prompt information such as measurement information, menu prompt information, error information, and power on and off is displayed

Ergonomic all-metal housing design, sturdy, compact, portable, and reliable

Chinese/English language selection

It can be connected to a computer and printer

All parameters can be printed or any parameters set by the user can be printed

The calibration sample is made of optical glass matrix, which has high precision, is not easy to scratch, and has a long service life

Complete accessories, optional curved surface sensor, deep groove sensor, small hole sensor, very small hole sensor, tooth surface sensor, small column, trim platform, extension rod, lateral adapter rod and other accessories

Applications

Machining and manufacturing industry, mainly metal processing and manufacturing

With the progress and development of science and technology, more and more new materials are applied to processing technology, such as ceramics, plastics, polyethylene, and so on

The roughness of the coupling on the switch, integrated circuit semiconductor, etc. is also required to be evaluated in the production and processing process

Operating Conditions

Ambient temperature: operating temperature -20°C~+40°C

Storage temperature: -30°C~+70°C

Relative Humidity≤90%

There is no strong vibration, no strong magnetic field, no corrosive medium and no serious dust in the surrounding environment

- 1Parameter analysis of surface roughness meter

- 2Specific measurement method of needle type surface roughness meter

- 3What are the surface finish measurement tools?

BC-190

BC-190