MODERNER CDS-2 laboratory horizontal sand mill 2L

Moderner CDS-2 Laboratory horizontal sand millSPEC

Moderner CDS-2 Laboratory horizontal sand millDetails

Moderner CDS-2 Laboratory horizontal sand millPacking list

- SKU

- NB018633

- Simplified Capacity area

- 2L

- Motor Power

- 3Kw、380V x 50HZ x 3P

- Speed regulation range

- 0~2000rpm

- conveyor pump

- 1/2 diaphragm pump

- compressed air

- ≥0.3Mps

- Fineness of ground

- 0.5~10μm

- Dimensions

- 850x680x750mm

- Weight

- 100Kg

- Grinding medium

- Pure zirconia beads

- Speed regulation mode

- Frequency conversion speed regulation

Introduction

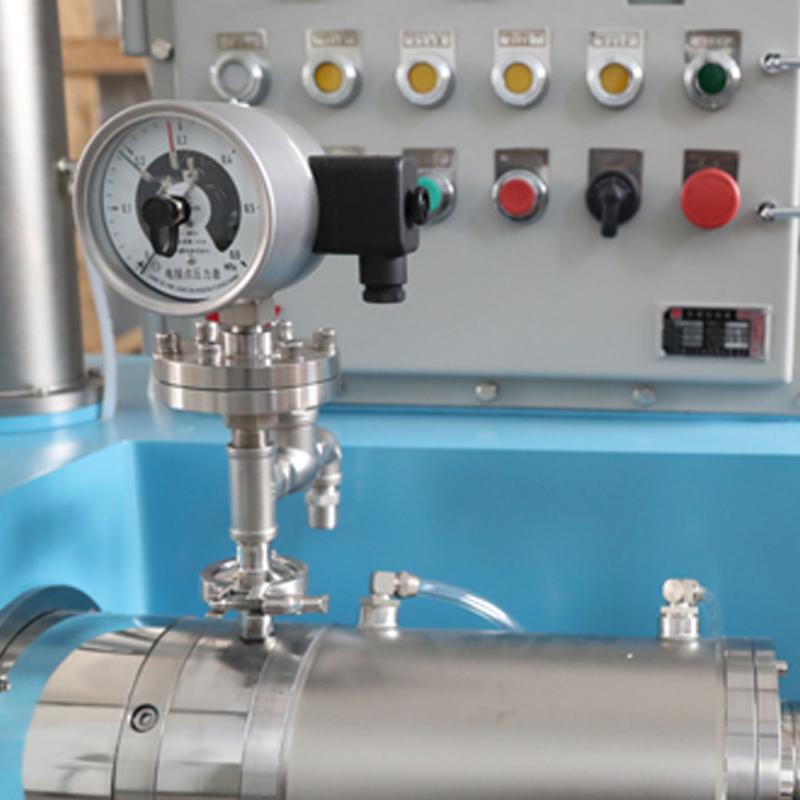

The CDS-2 laboratory horizontal sand mill is a grinding and dispersing equipment with a horizontal grinding cylinder and a rotor pin-type Grinder. It is suitable for ultra-fine grinding of solid-liquid two-phase suspensions. It is widely used in industrial sectors such as coatings, inks, ultrafine powders of non-metallic minerals, dyes, and magnetic recording materials, as well as in laboratories of scientific research institutes in universities and colleges. This machine is easy to use and is the ultrafine grinding test equipment needed in laboratories. .

Principle

The main motor drives the main shaft rotor to rotate at high speed through the V-shaped belt, and the dispersing device (grinding rod) on the rotor drives the grinding medium to move at high speed, thereby generating great impact, friction and shearing force, so that the material can be fully ground and dispersed .

The machine adopts precision and reliable mechanical seal, which has extremely high reliability and durability. The grinding cylinder is completely sealed, which can avoid the mixing of air, the generation of bubbles, the volatilization of solvents and reduce environmental pollution.

This machine uses a dynamic separator to separate the grinding media and the materials to be ground. Due to the self-cleaning function of the device, the grinding media will not be blocked in the gaps, which can extend the service life of the equipment and expand the Application for high-viscosity materials.

CDS-2

CDS-2