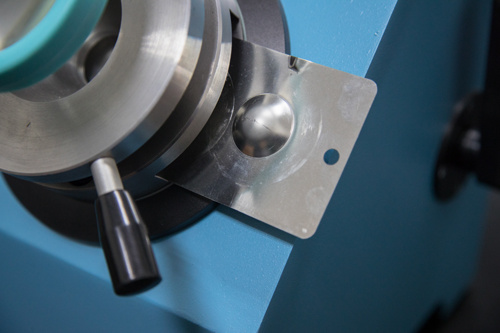

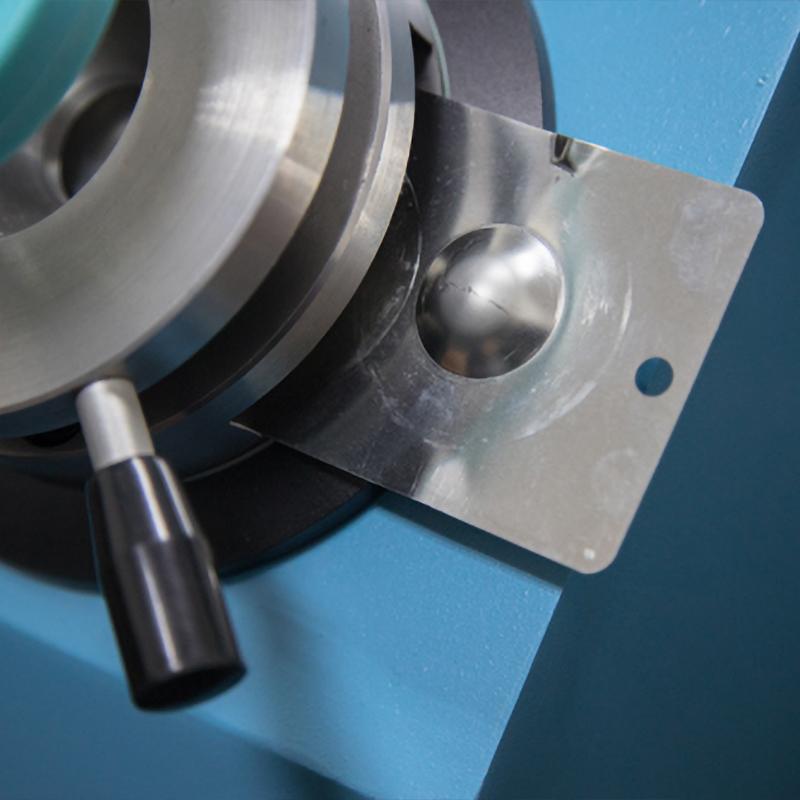

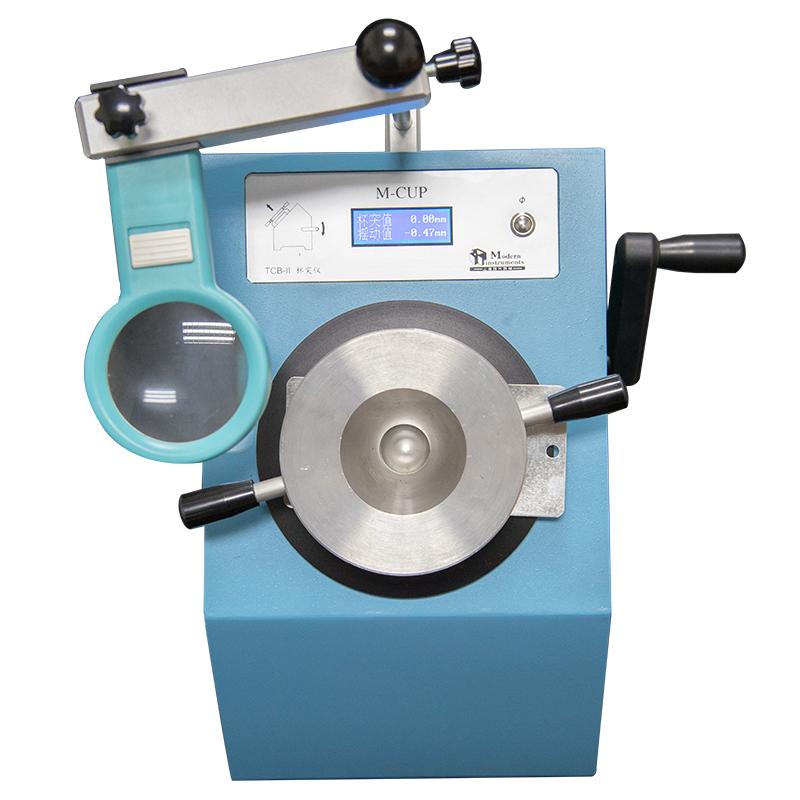

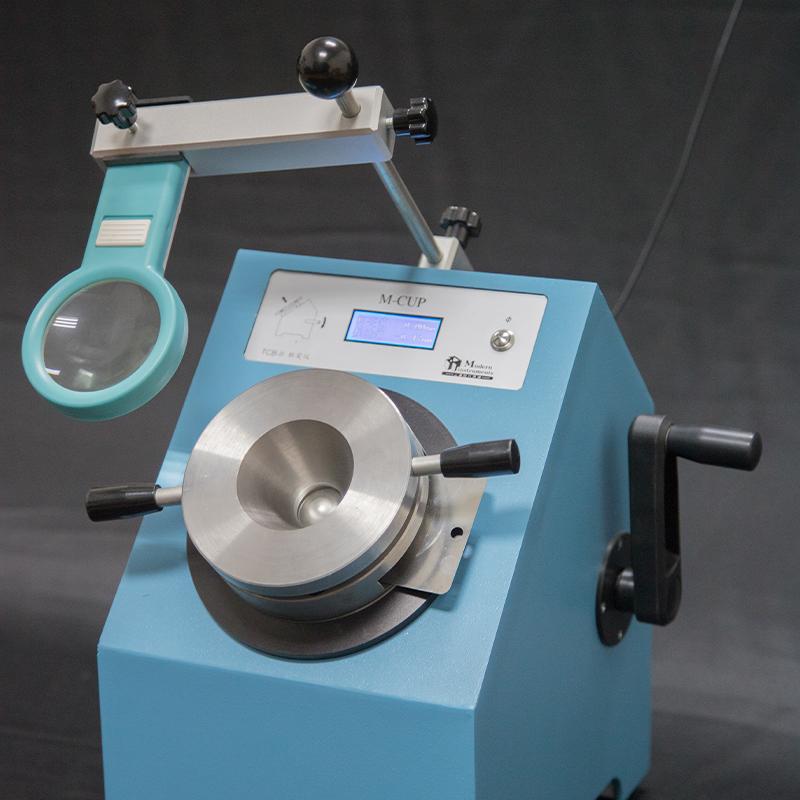

MODERNER TCB-II digital cupping instrument, ball diameter 20mm

SEModerner TCB-II Digital cupping instrumentSPEC

Moderner TCB-II Digital cupping instrumentDetails

Moderner TCB-II Digital cupping instrumentPacking list

- SKU

- NB018634

- Striker Diameter

- F20mm

- Maximum jacking height

- 10mm

- Height display digits

- 00.00mm (division 0.01mm)

- Height display Accuracy

- 0.1mm

- displacement per revolution

- 0.4mm/r

- Test board size

- 70*70mm

- Weight

- 24KG

- Film thickness

- d = 0.30-1.25mm

Introduction

The cupping Tester is commonly used to evaluate the resistance of paints, varnishes and related products to cracking or detachment of the substrate during the process of gradual convex deformation. TCB-II cupping Tester complies with ISO 1520:2006 international standard (the relevant national standard is GB/T 9753-2007), its principle is to press the test plate from above with a fixed ring with an opening; Press the test plate from bottom to top at a slow speed, so that the test plate forms a hemispherical convex deformation in the middle of the fixed ring; visually observe whether the raised test plate is cracked or detached from the substrate through a magnifying glass, and the initial crack or The protrusion height at the time of detachment from the substrate was used as an evaluation index.

The cupping instrument is used in the testing process of chemical raw materials. Users should establish appropriate safety and health protection measures and determine rules and regulations according to relevant safety regulations before use.

Features

1) The operation surface of TCB-II cupping instrument adopts inclined layout, which is convenient for observation;

2) The spherical head is raised and lowered by the side wheel type shaking hand, the operation is more stable, and it can be changed left and right;

3) The display adopts LCD, which simultaneously displays the cupping value (the current maximum jacking value) and the shaking value (using positive and negative values to indicate the current position of the jack);

4) It can be used immediately after turning on the machine. There is no requirement for the test board to conduct electricity, and there is no need to reset the machine every time the machine is turned on.

- 1WJ 2669-2005《Specification for cathode electrophoresis paint for shell》

- 2GB/T 22638.11-2023《Test methods for aluminum and aluminum alloy foils—Part 11: Determination of mechanical properties》

- 3GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 4HG/T 2006-2006《Thermosetting powder coatings》

- 5TB/T 2260-1991《Technical conditions for supply of anti-rust primers for railway rolling stock》

- 6HG/T 5370-2018《Waterborne coatings for bicycles》

- 7HG/T 5367.1-2018《Coatings for rail transit vehicles - Part 1: Waterborne coatings》

- 8GB/T 1981.2-2009《Varnishes used for electrical insulation - Part 2: Methods of test》

- 9GB/T 9271-2008《Paints and varnishes standard panels for testing》

- 10ISO 1520-2006《Paints And Varnishes - Cupping Test》

TCB-II

TCB-II